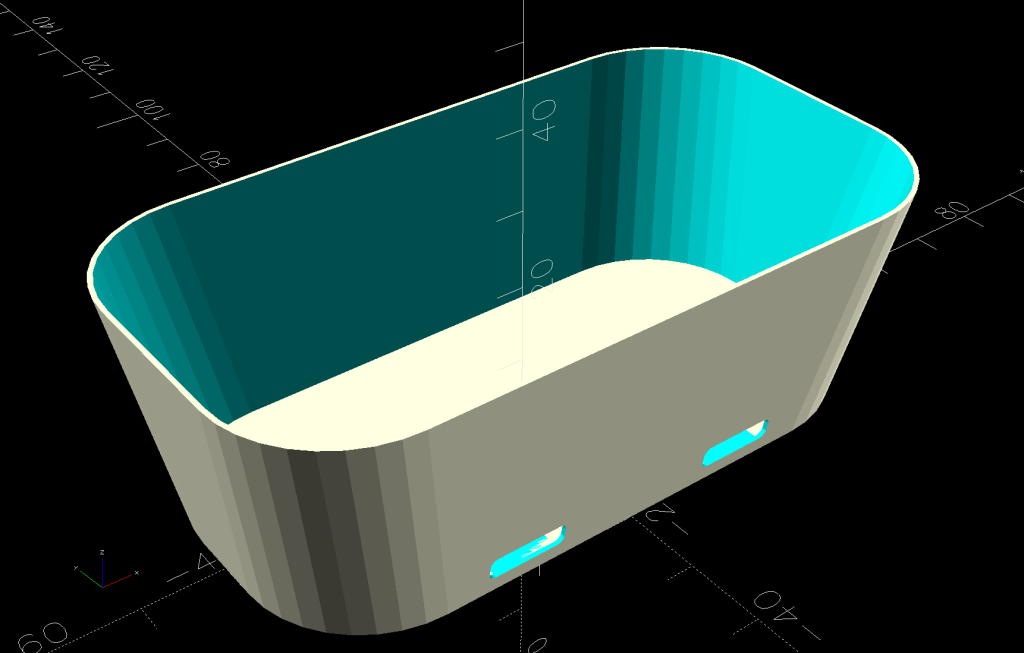

A SquidWrench meeting discussion about printing transparent objects prompted me to conjure a soap dish from the vasty digital deep:

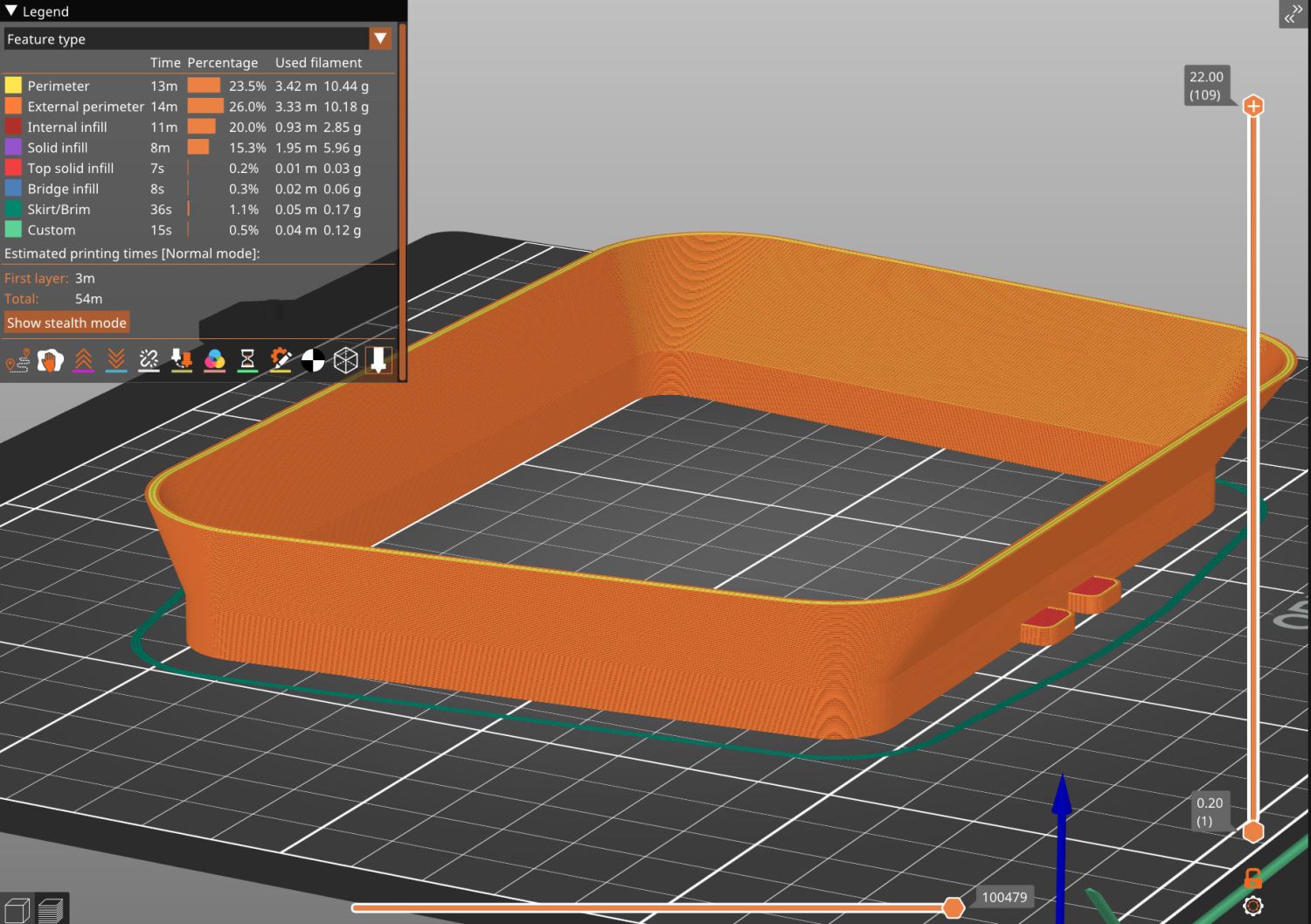

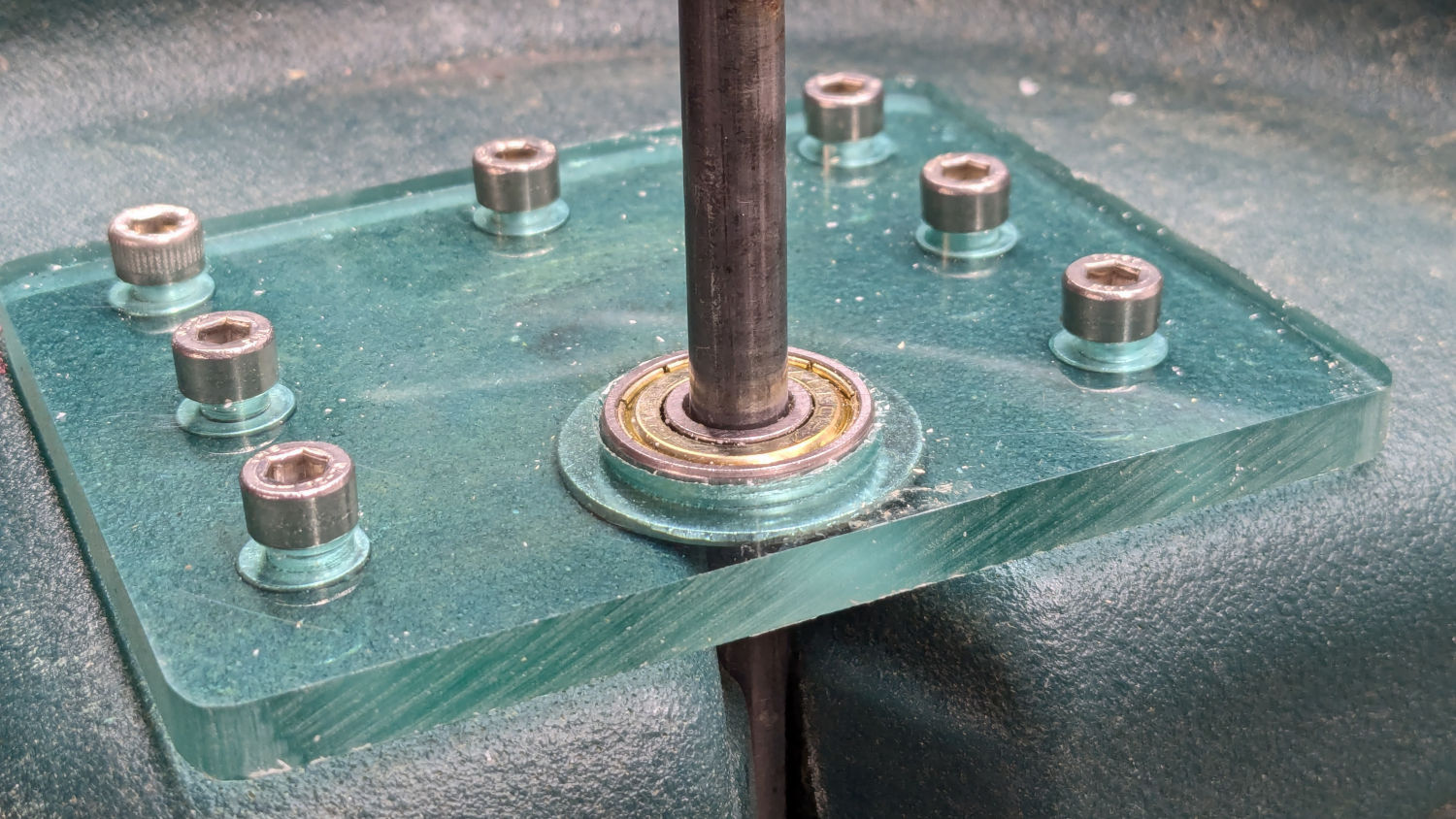

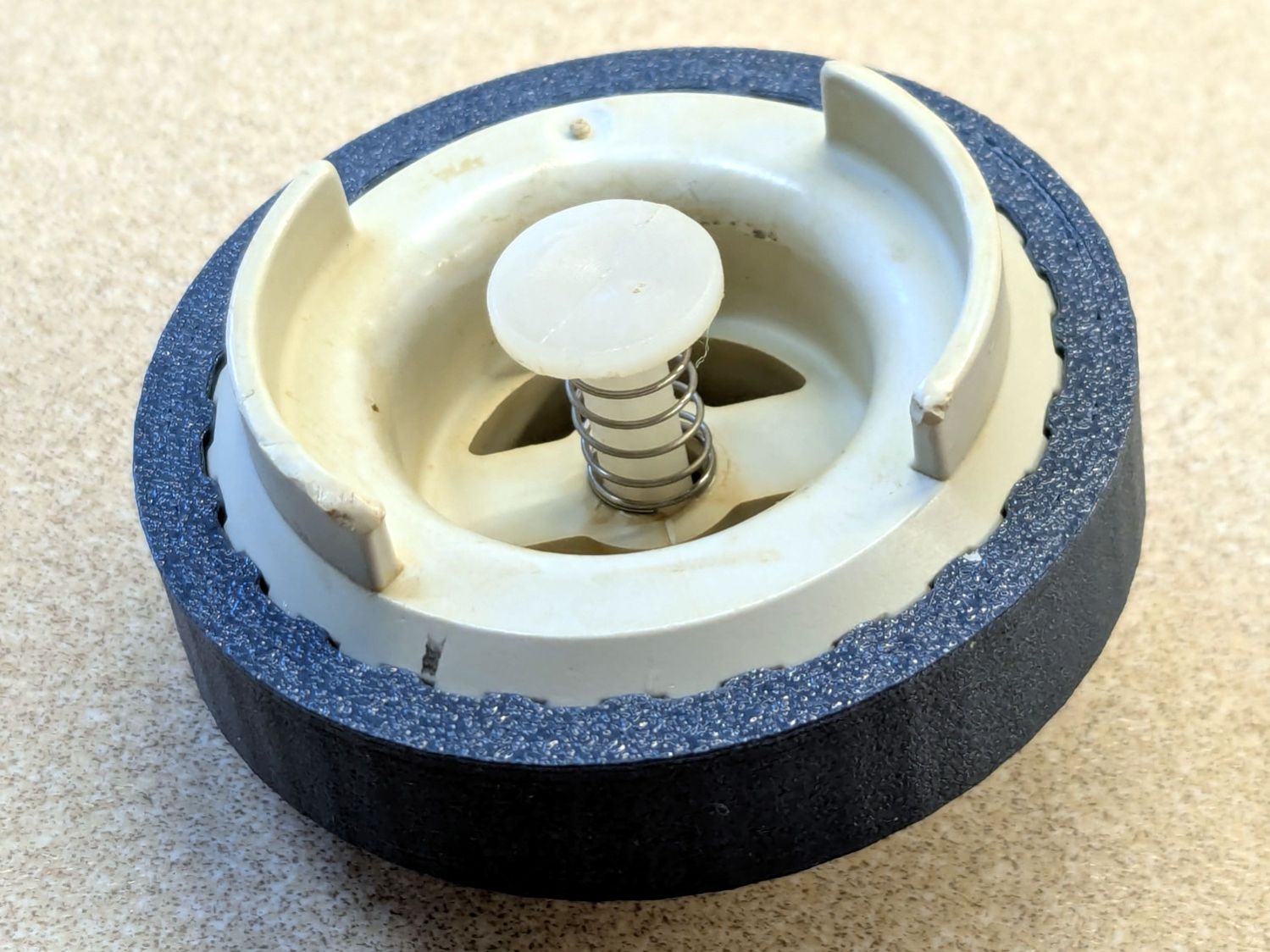

They’re all done in “natural” PETG with sufficient variations in speed, temperature, extrusion multiplier, and fill pattern to stock the shower & tub:

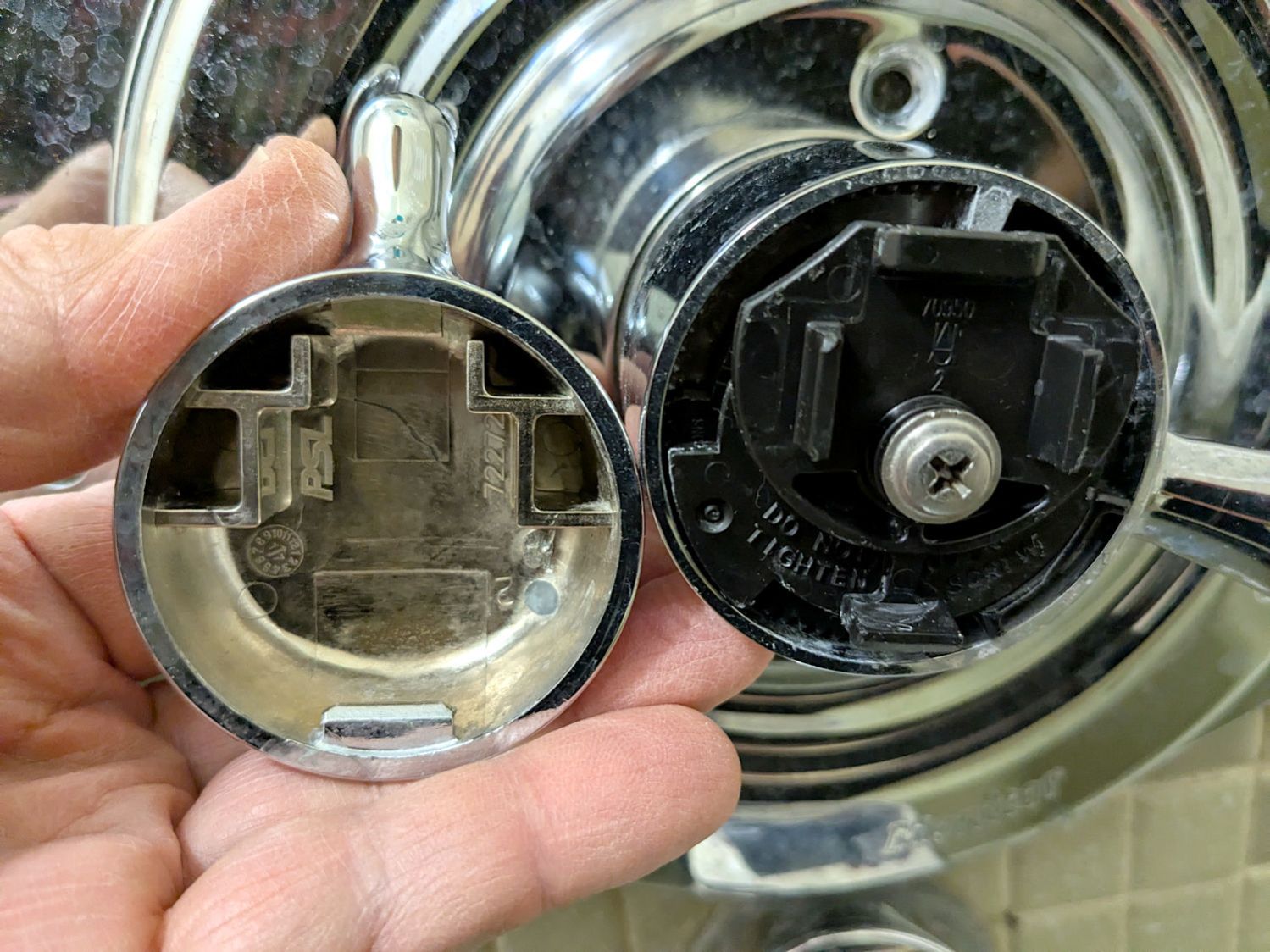

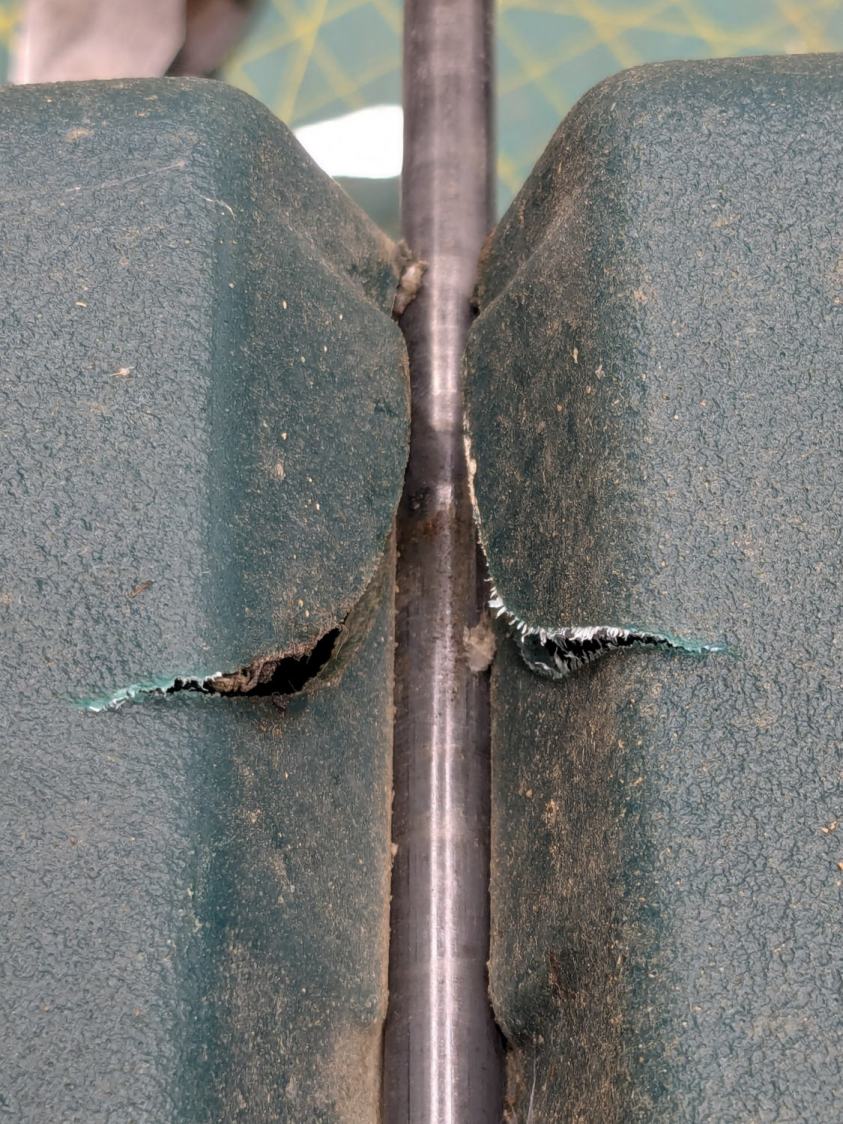

The single-thread sidewalls came out reasonably translucent in all the variations, but the baseplate remained stubbornly white-ish, even at 20 mm/s and 250 °C with 100% infill. The seams where the extruder retracts and lifts to the next layer remain conspicuous, with a scarf joint forming the white slab in the left-rear dish.

Quite a while ago, I’d considered making soap dishes with shattered-glass bottoms, but came to my senses. These have some key advantages:

- Exactly the right size for narrow shower shelves

- Light enough to not damage anything when it inevitably falls off

- Reasonably unbreakable when that happens

- Easily replaced

They’re also test pieces for the whole transparency thing, so it’s all good.

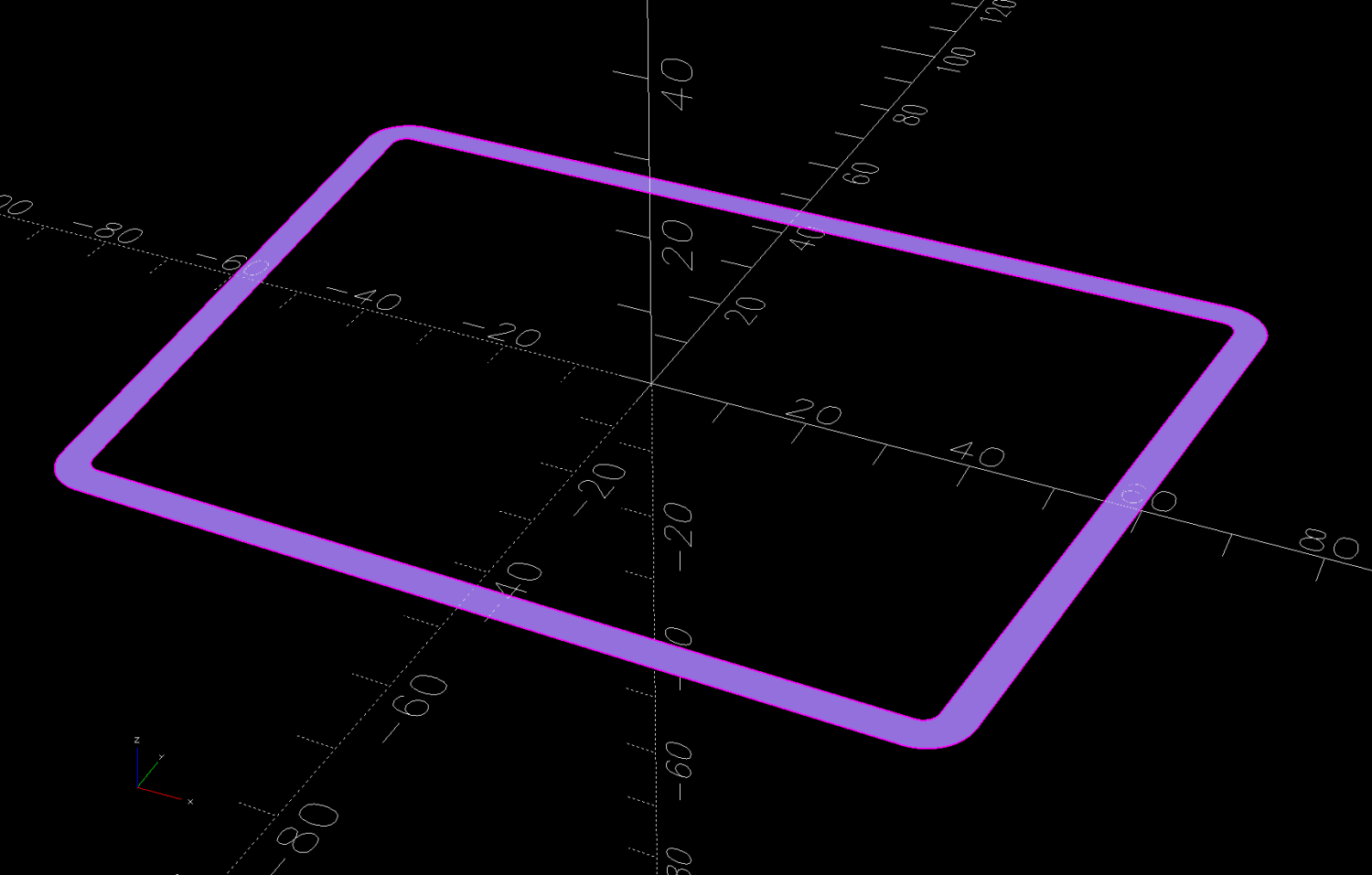

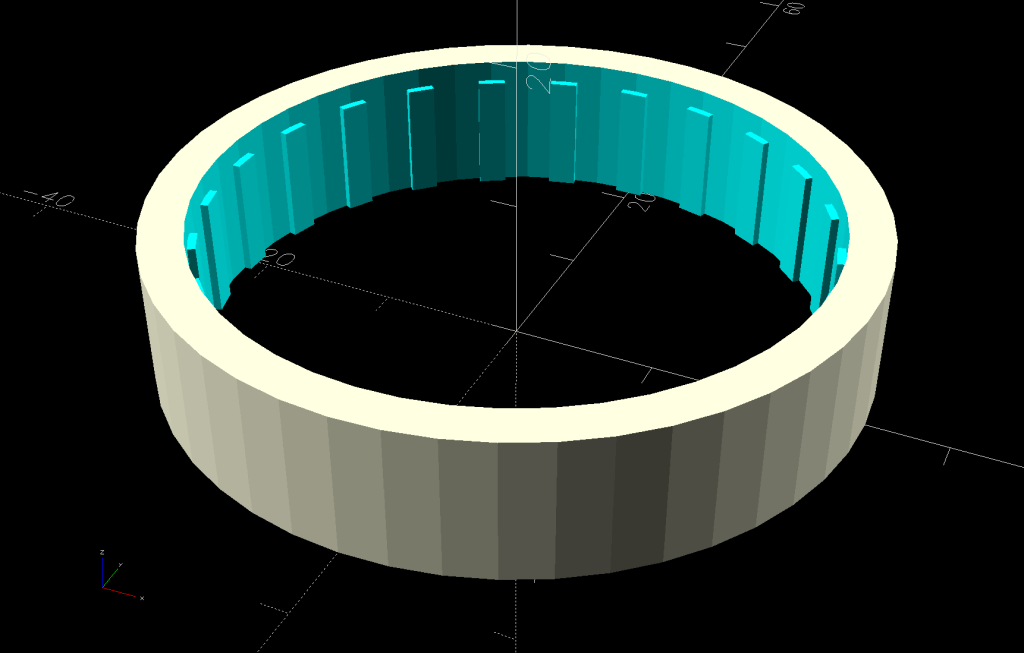

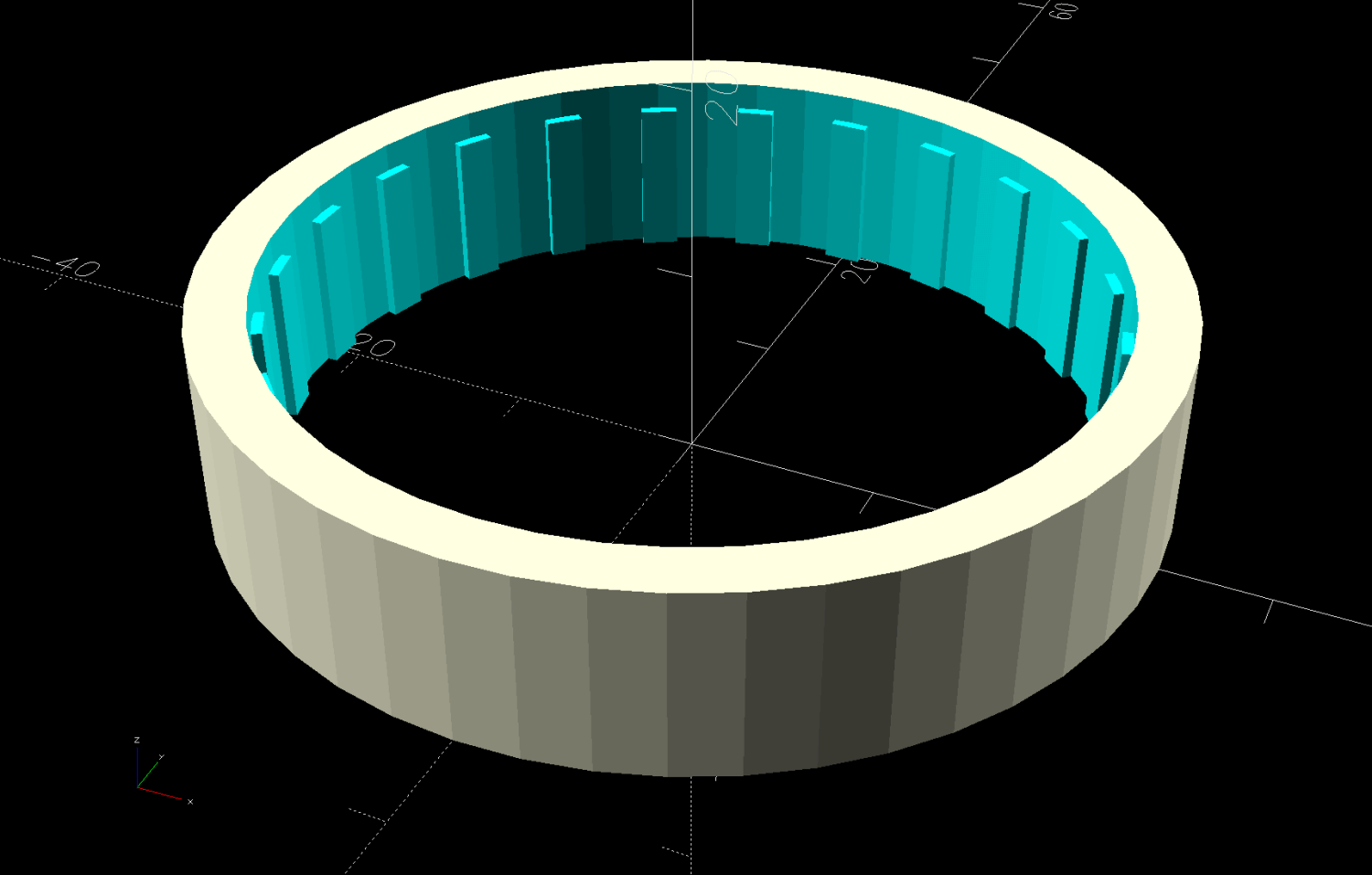

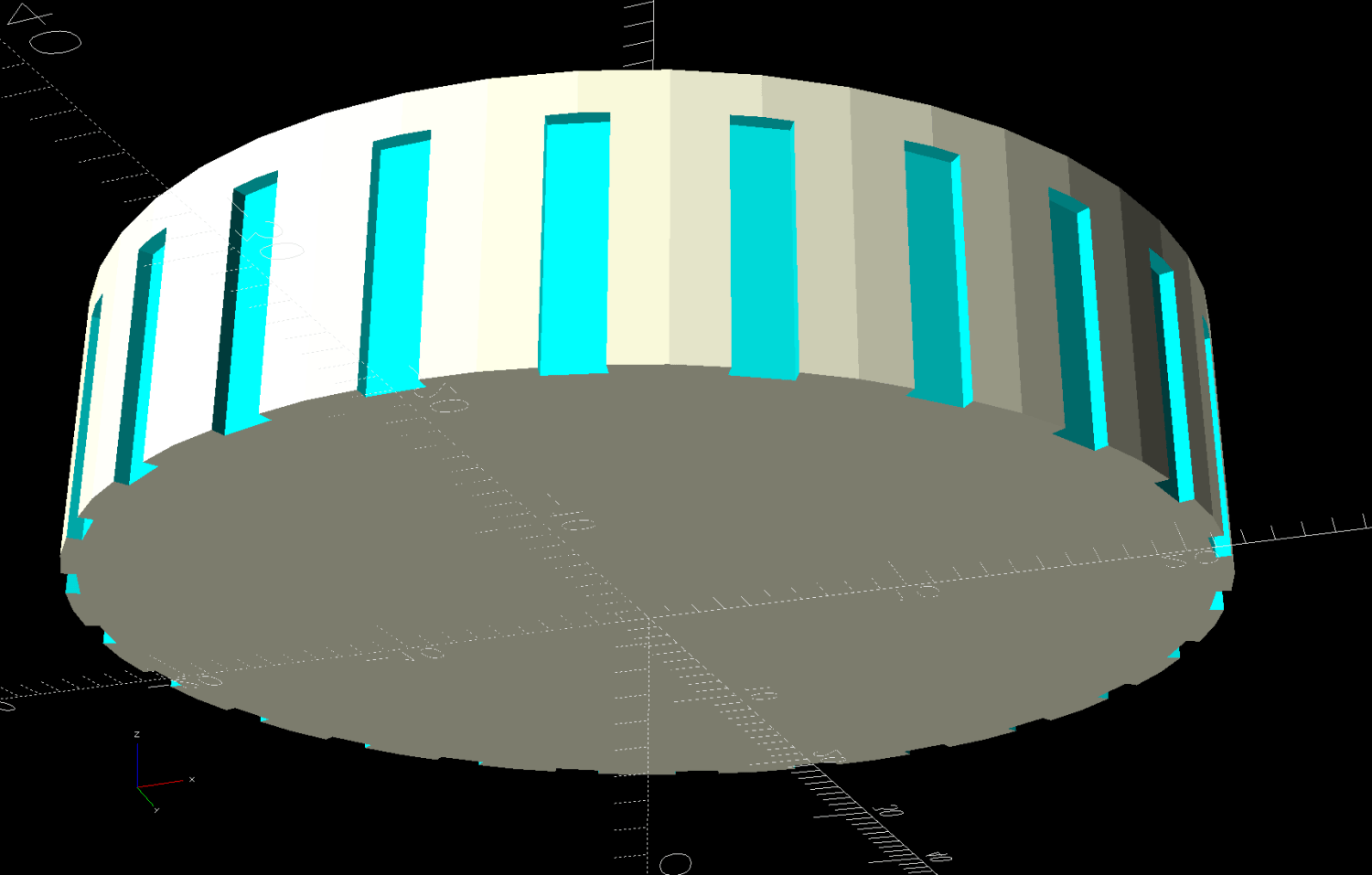

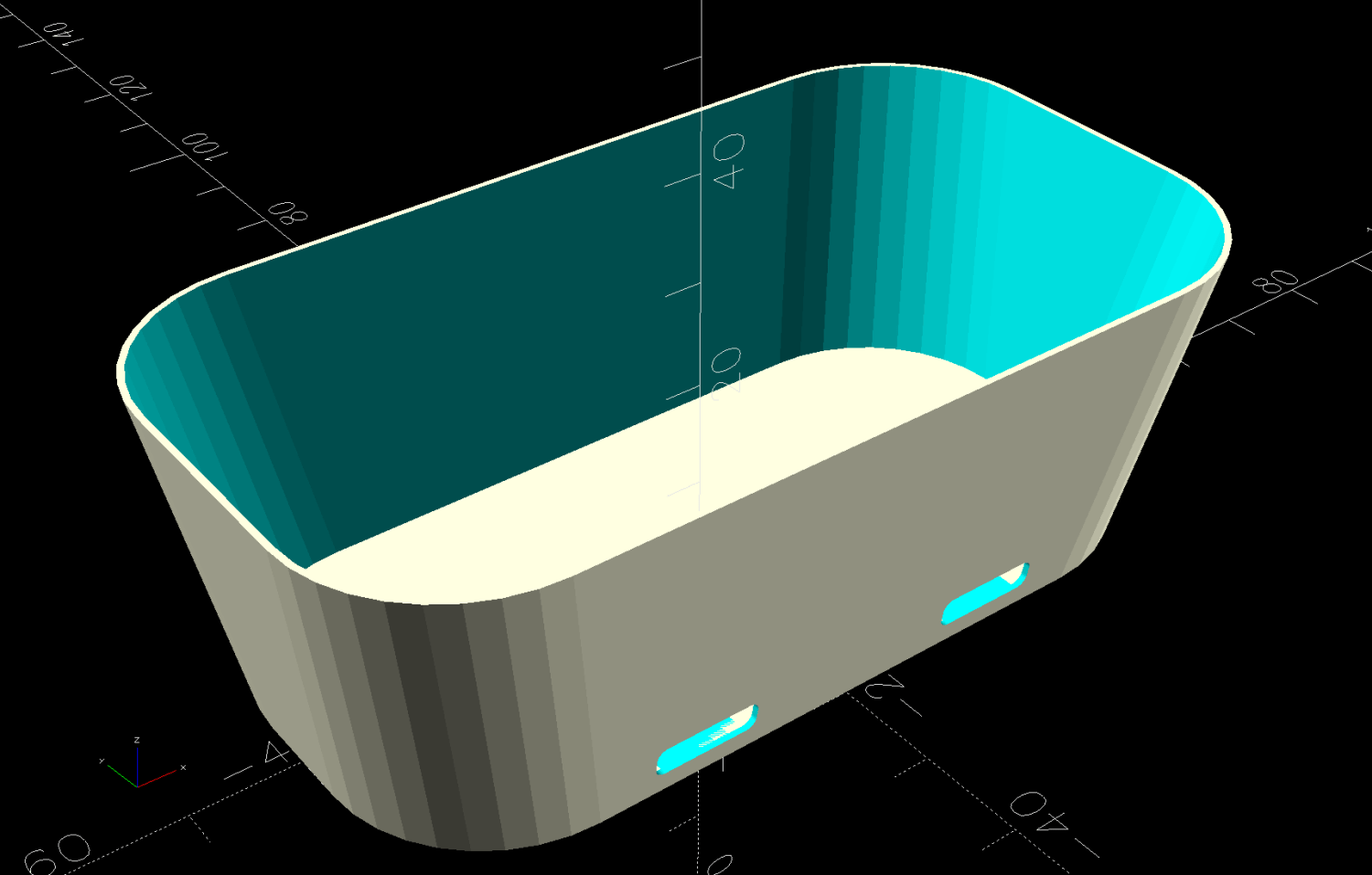

The OpenSCAD source code as a GitHub Gist:

| // Shower soap dish | |

| // Ed Nisley – KE4ZNU | |

| // 2026-01-13 | |

| include <BOSL2/std.scad> | |

| /* [Hidden] */ | |

| HoleWindage = 0.2; | |

| Protrusion = 0.1; | |

| NumSides = 3*3*4; | |

| $fn=NumSides; | |

| ID = 0; | |

| OD = 1; | |

| LENGTH = 2; | |

| WallThick = 0.6; | |

| BaseThick = 2.0; | |

| //DishOA = [80.0,40.0,20.0]; // standing used Dove | |

| DishOA = [90.0,50.0,30.0]; // standing Dove | |

| //DishOA = [100.0,65.0,30.0]; // half-bar | |

| DishTaper = [10.0,10.0]; | |

| CornerRadius = 15.0; | |

| DrainOA = [10.0,DishOA.y,3.0]; | |

| DrainOC = DishOA.x/3; | |

| //———- | |

| // Build it | |

| difference() { | |

| union() { | |

| linear_extrude(BaseThick) | |

| rect([DishOA.x,DishOA.y] – DishTaper,rounding=CornerRadius); | |

| rect_tube(DishOA.z,wall=WallThick, | |

| size1=[DishOA.x,DishOA.y] – DishTaper,size2=[DishOA.x,DishOA.y], | |

| rounding=CornerRadius,anchor=BOTTOM); | |

| } | |

| for (j=[-1,1]) | |

| right(j*DrainOC/2) | |

| up(BaseThick) | |

| cuboid(DrainOA,rounding=1.0,anchor=BOTTOM+BACK); | |

| } |