|

// Power Supply Brick brackets |

|

// Ed Nisley KE4ZNU 2024-08-19 |

|

|

|

Layout = "Show"; // [Show,Build] |

|

|

|

//– Extrusion parameters |

|

|

|

/* [Hidden] */ |

|

|

|

ThreadThick = 0.20; |

|

ThreadWidth = 0.45; |

|

|

|

HoleWindage = 0.3; // enlarge hole dia by this amount |

|

|

|

function IntegerMultiple(Size,Unit) = Unit * ceil(Size / Unit); |

|

|

|

Protrusion = 0.1; // make holes look good and joints intersect properly |

|

|

|

//– Useful sizes |

|

|

|

ID = 0; |

|

OD = 1; |

|

LENGTH = 2; |

|

|

|

//– Bracket Dimensions |

|

|

|

Brick = [115.0,51.0,32.0]; // overall size, add details in module |

|

|

|

Socket = [20.0,10.0]; // binocular power socket |

|

Cable = [5.0,12.0]; // DC output cable ID=wire OD=strain relief |

|

|

|

//Socket = [30.0,24.0]; // IEC power socket |

|

//Cable = [6.0,15.0]; // DC output cable ID=wire OD=strain relief |

|

|

|

WallThick = 3.0; // default wall thickness |

|

BaseThick = 4.0; |

|

|

|

Screw = [5.1,10.0,3.0]; // screw size, more-or-less 10-32, OD & LENGTH for head |

|

|

|

NumSides = 3*4; |

|

|

|

//———————- |

|

// Useful routines |

|

|

|

module PolyCyl(Dia,Height,ForceSides=0) { // based on nophead's polyholes |

|

|

|

Sides = (ForceSides != 0) ? ForceSides : (ceil(Dia) + 2); |

|

|

|

FixDia = Dia / cos(180/Sides); |

|

|

|

cylinder(r=(FixDia + HoleWindage)/2, |

|

h=Height, |

|

$fn=Sides); |

|

} |

|

|

|

//———————- |

|

// Models |

|

|

|

module BrickMount(End="Both") { |

|

|

|

difference() { |

|

union() { |

|

hull() // main block |

|

for (i=[-1,1], j=[-1,1], k=[0,1]) |

|

translate([i*(Brick.x/2 + WallThick – WallThick), |

|

j*(Brick.y/2 + WallThick – WallThick), |

|

k*(Brick.z + WallThick – WallThick)]) |

|

sphere(r=WallThick,$fn=NumSides); |

|

hull() // screw flanges |

|

for (i=[-1,1], j=[-1,1]) |

|

translate([i*(Brick.x/2 + WallThick – BaseThick), |

|

j*(Brick.y/2 + WallThick + 2*Screw[OD] – BaseThick), |

|

0]) |

|

sphere(r=BaseThick,$fn=NumSides); |

|

} |

|

for (i=[-1,1], j=[-1,1]) // remove screw holes |

|

translate([i*(Brick.x/2 + WallThick – Screw[OD]), |

|

j*(Brick.y/2 + WallThick + Screw[OD]), |

|

-Protrusion]) |

|

rotate(180/6) |

|

PolyCyl(Screw[ID],2*WallThick,6); |

|

|

|

translate([0,0,Brick.z/2]) // remove center part to leave ends |

|

cube([(Brick.x + 2*WallThick – 4*Screw[OD]),2*Brick.y,2*Brick.z],center=true); |

|

|

|

if (End == "Socket") |

|

translate([Brick.x/2,0,Brick.z/2]) // remove cable end to leave socket |

|

cube([(Brick.x + 2*WallThick – 4*Screw[OD]),2*Brick.y,2*Brick.z],center=true); |

|

|

|

if (End == "Cable") |

|

translate([-Brick.x/2,0,Brick.z/2]) // remove socket end to leave cable |

|

cube([(Brick.x + 2*WallThick – 4*Screw[OD]),2*Brick.y,2*Brick.z],center=true); |

|

|

|

translate([0,0,Brick.z/2 – Protrusion/2]) // remove power supply brick from interior |

|

cube(Brick + [0,0,Protrusion],center=true); |

|

|

|

translate([0,0,-Brick.z]) // remove below XY plane |

|

cube(2*Brick,center=true); |

|

|

|

translate([0,0,Brick.z/2]) // remove AC socket |

|

rotate([0,-90,0]) |

|

rotate(90) |

|

linear_extrude(height=Brick.x,convexity=2) |

|

square(Socket,center=true); |

|

|

|

translate([0,0,Brick.z/2]) // remove DC cable |

|

rotate([0,90,0]) |

|

rotate(180/8) |

|

PolyCyl(Cable[OD],Brick.x,8); |

|

|

|

translate([Brick.x/2,0,Brick.z/4 – Protrusion/2]) // … and wire slot |

|

cube([Brick.x,Cable[ID],Brick.z/2 + Protrusion],center=true); |

|

} |

|

|

|

} |

|

|

|

//———————- |

|

// Build it |

|

|

|

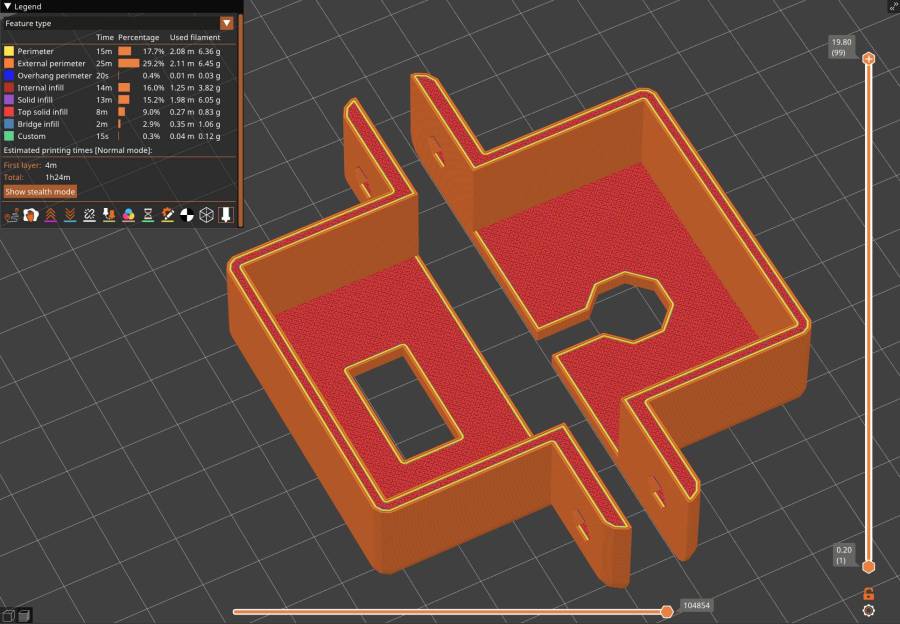

if (Layout == "Show") |

|

BrickMount("Both"); |

|

|

|

if (Layout == "Build") { |

|

translate([5,0,Brick.x/2 + WallThick]) |

|

rotate([0,90,0]) |

|

BrickMount("Cable"); |

|

translate([-5,0,Brick.x/2 + WallThick]) |

|

rotate([0,-90,0]) |

|

BrickMount("Socket"); |

|

} |

|

|