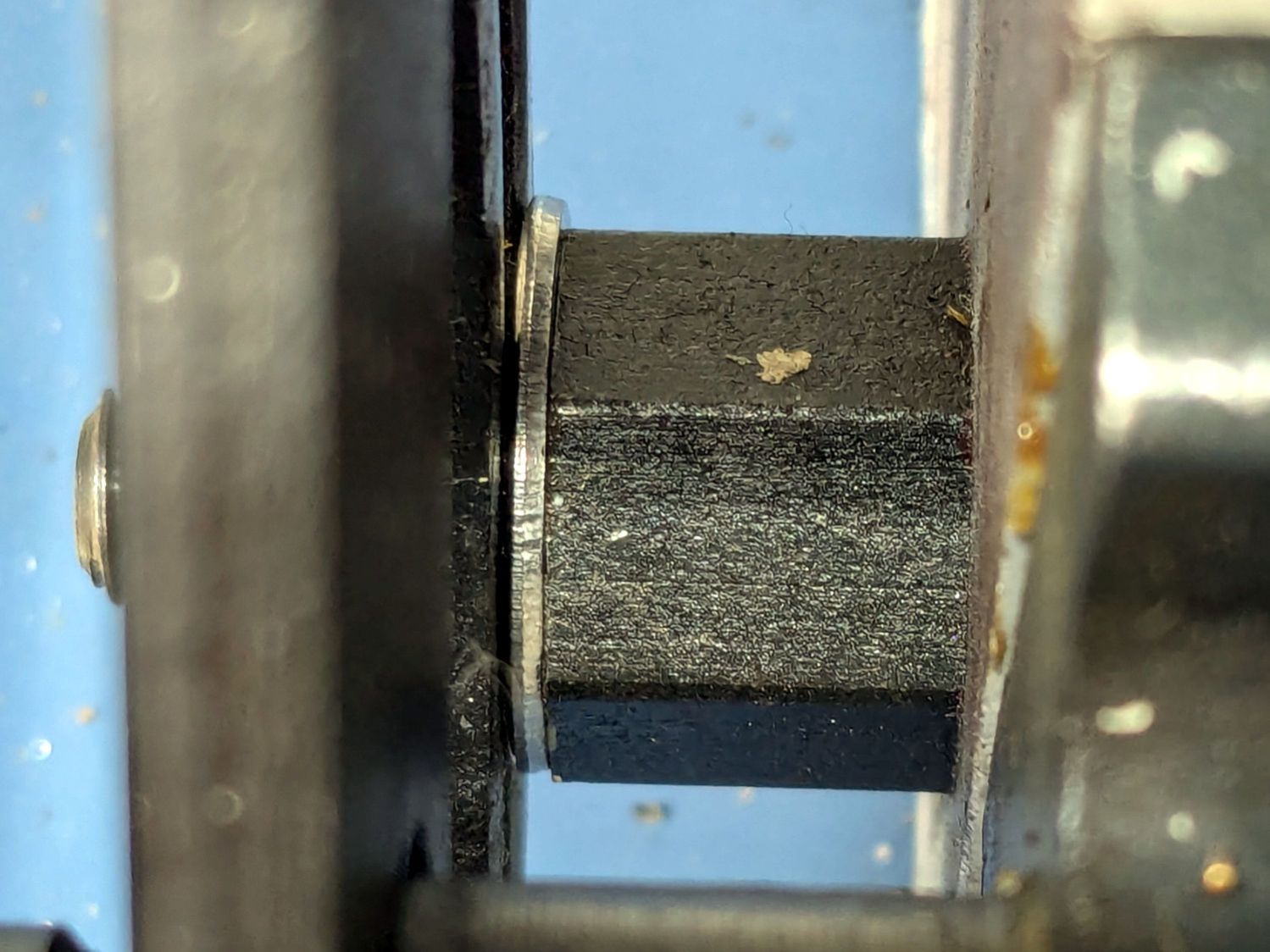

I intended to single-point a few turns on an 8 mm axle to ease running an M8-1.25 die over it, thus making a thread for a nut securing a wheel (about which, more later). This required selecting the change gears for a 1.25 mm thread pitch, the installation of which proved sufficiently awkward to give me the opportunity to discover a washer spacing the banjo just a little farther outward would improve the gear alignment:

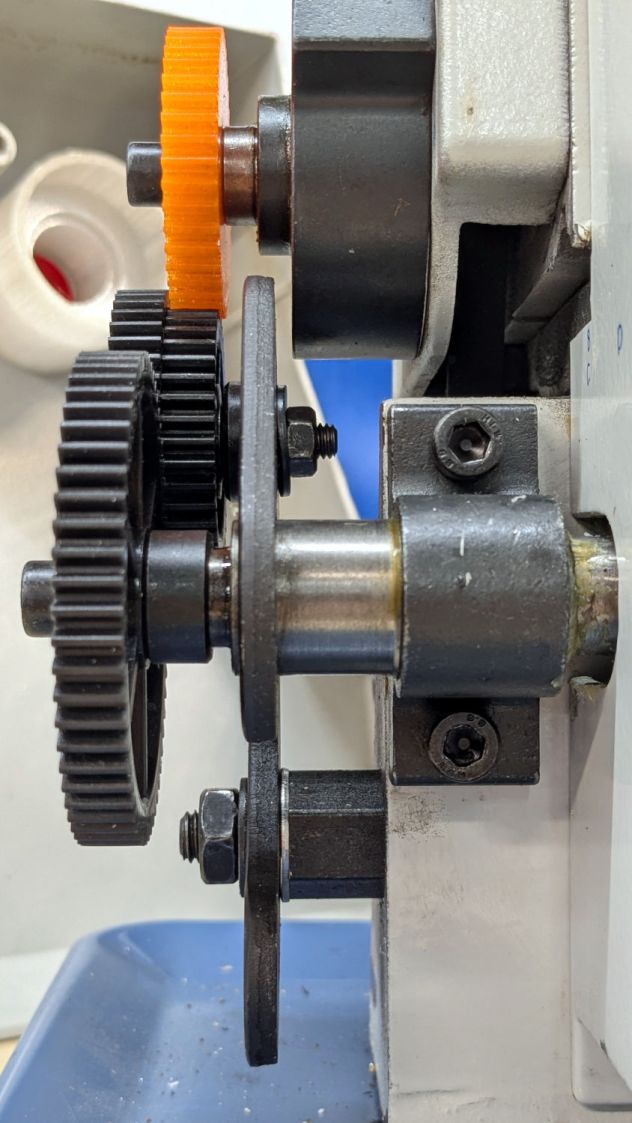

The overview shows how moving the whole banjo just a bit leftward better aligned black Gear B with respect to orange Gear A:

From A to D, a 1.25 mm pitch uses 42 40 45 60 tooth gears. The 42 tooth gear supplies the magic required to convince a hard-inch 16 TPI leadscrew to produce good-enough metric pitches.

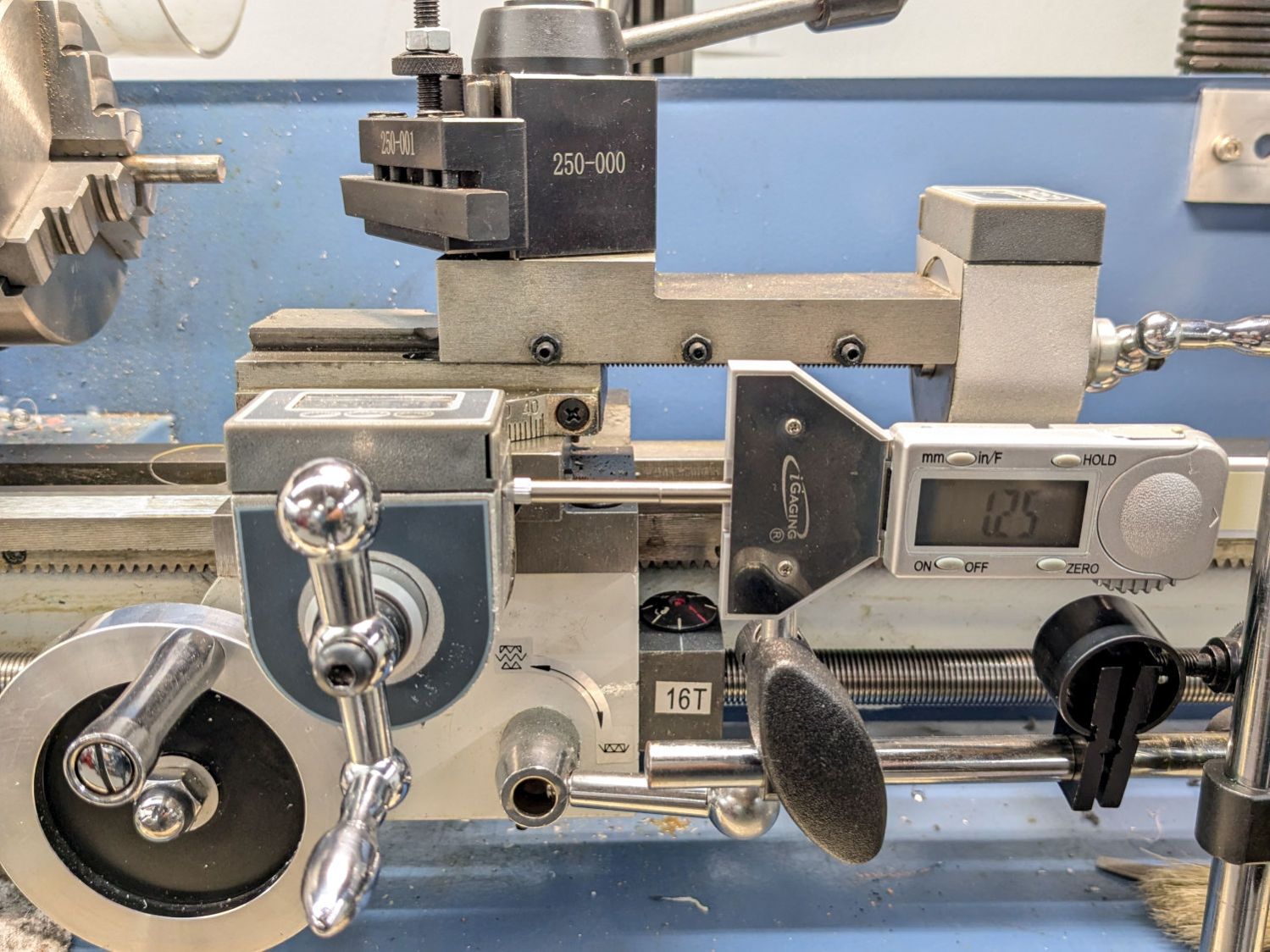

In addition to the usual hassle, the main reason the process took so long is doing having to do it twice. After I swapped Gear C and Gear B on the jockey shaft in the middle, the leadscrew produced the correct 1.25 mm motion for one turn of the chuck:

Measure twice, cut once …

Spam comments get trashed, so don’t bother. Comment moderation may cause a delay.