The measurements:

| 2025-11-04 | 2025-11-11 | 2025-11-19 | ||||

| Filament | %RH | %RH | Weight – g | Wt gain – g | Gain % | %RH |

| PETG White | 39 | 39 | 27.4 | 2.4 | 9.6% | 23 |

| PETG Black | 25 | 26 | 26.7 | 1.7 | 6.8% | 14 |

| PETG Orange | 30 | 23 | 26.5 | 1.5 | 6.0% | 23 |

| PETG Blue | 18 | 23 | 27.0 | 2.0 | 8.0% | 10 |

| PETG-CF Blue | 25 | 25 | 26.5 | 1.5 | 6.0% | 18 |

| PETG-CF Black | 22 | 22 | 26.3 | 1.3 | 5.2% | 14 |

| PETG-CF Gray | 28 | 28 | 26.5 | 1.5 | 6.0% | 18 |

| Empty → PETG Clear | 31 | n/a | 26.8 | 1.8 | 7.2% | 18 |

| TPU – Clear | 28 | 29 | 26.3 | 1.3 | 5.2% | 14 |

| W empty → TPU – K | 23 | 27 | 26.8 | 1.8 | 7.2% | 18 |

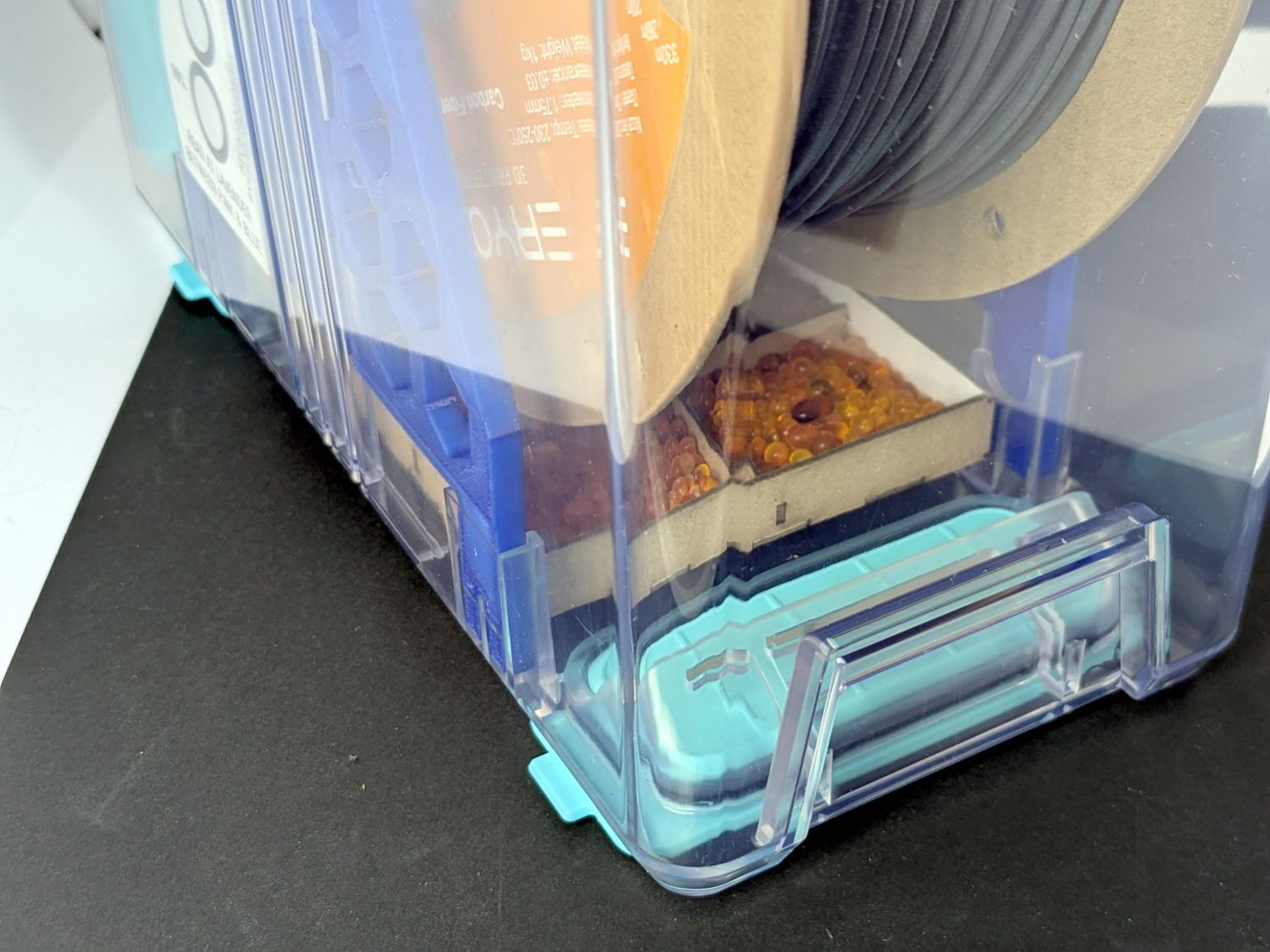

All the boxes now have filament spools and 50 g of silica gel divided equally between the humidity meter and the tray in the bottom of the box:

The PETG White in the first row is the new spool loaded last month. I think the 39 %RH indicates the spools do not necessarily arrive bone-dry in their vacuum-sealed bags with a tiny desiccant packet.

Conversely, both the PETG Clear and TPU K filaments are new spools that seem reasonably dry out of their bags.

The auto-rewind spindle in the PETG Orange filament hasn’t been working quite right, so I opened the box a few times. It now has a new PETG-CF spindle.

Spam comments get trashed, so don’t bother. Comment moderation may cause a delay.