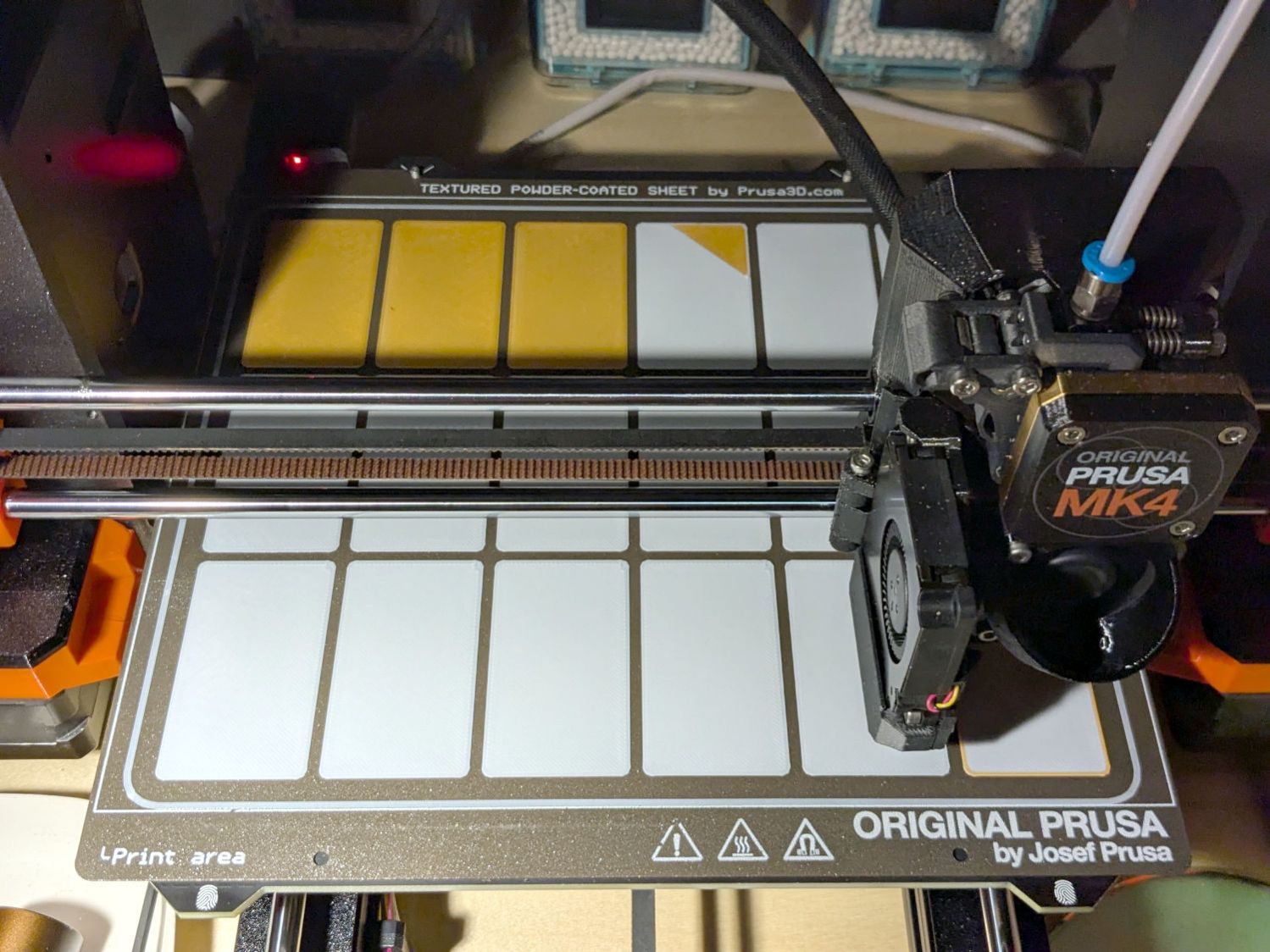

Because nobody will ever see the Radiator Sleds, I started a batch with the tail end of the white PETG spool and set up the Spool Join function to switch to the retina-burn orange PETG when the white filament ran out.

The two colors combined nicely on that layer:

Unfortunately, the Spool Join didn’t work out quite right and I had to extricate the white filament from the MMU3, then coerce the orange filament into position.

The key section of the MMU3 looks like this:

The Selector assembly rides on the smooth rods, driven by the stepper motor on the far end of the leadscrew. It stops at one of the five filament tubes (visible to the left of the upper smooth rod, with filament tips showing), whereupon a drive gear pushes the filament into the Selector, under the FINDA sensor (the threaded fitting sticking out of the top), into the PTFE tube, down to the Nextruder, through the idler to trip the Filament Sensor, then into the extruder’s planetary drive gear.

I think this happened:

- The rear end of the white filament passed through the FINDA sensor

- The MK4 reversed the Nextruder to drive the filament back into the MMU3

- The rear end of the filament didn’t reenter its filament tube and escaped out to the side

- The MMU3 drive gear couldn’t pull the filament backward, because the back end was misplaced

- The Extruder planetary drive gear couldn’t pull the filament forward, because the front end was now above the gear

- Both the FINDA and the Filament Sensor showed the filament was present, so the MK4 knew something was wrong

Fortunately, I was watching the whole operation and could intervene.

The MMU3 works well when the filament behaves properly, but it’s very sensitive to bends in the filament and misshapen ends. In this case, the white filament had the usual tight curve due to being would around the spool hub, which was enough to mis-align its end with the MMU3 tube while backing out.

Trust, but verify.

Spam comments get trashed, so don’t bother. Comment moderation may cause a delay.