Flushed with success after building a Keychain Pill Tube with orange PETG, I tried dark gray carbon-fiber PETG with the same settings:

In real life, it’s a much darker gray.

It’s not only furry, it’s overstuffed: the threads didn’t engage at all.

Running a few single-thread calibration squares suggested an Extrusion Multiplier around 0.6 would produce the proper thread width. Making it so and trying again worked perfectly:

Not only did the cap screw on easily enough, the exterior finish improved and most of the stringing went away.

However, the Mighty Dragorn of Kismet (who nerd-sniped me into getting the MK4 in the first place) observed that he’d been running PETG-CF with stock PETG settings and getting good dimensional results without further tuning.

After a few more gyrations, I did what I should have done first:

The label on the spool suggests a 230 °C to 250 °C extrusion temperature and 235 °C seems like the sweet spot between overly stringy and terrible bridging, although I’d never expect PETG to cross that kind of gap without some support. The 35° overhangs on the left look surprisingly good at any temperature.

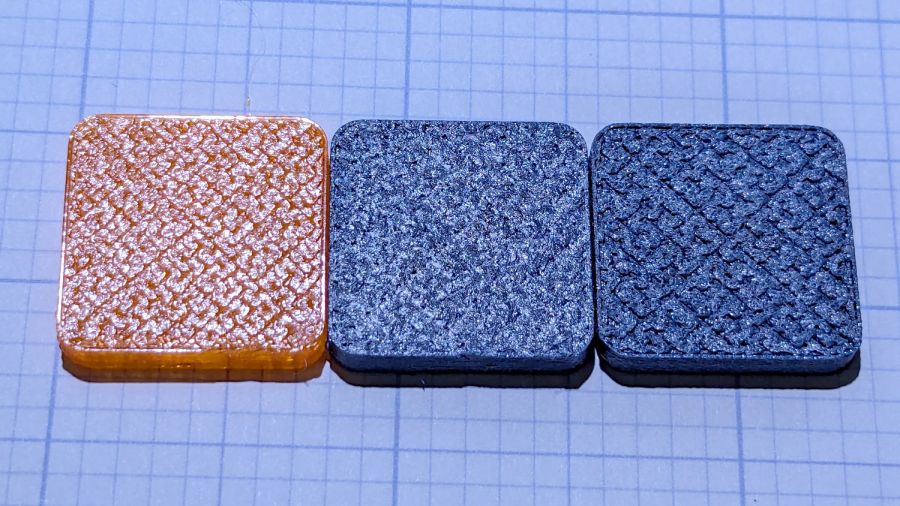

With that set up, running solid calibration squares showed Dragorn was right: 1.0 EM works the way you’d expect and 0.65 EM produces under-filled surfaces:

The hand-knitted surface is more visible at a more oblique angle:

The 0.2 mm layers look about the same on both squares.

Comparing plain PETG at 1.0 EM with those:

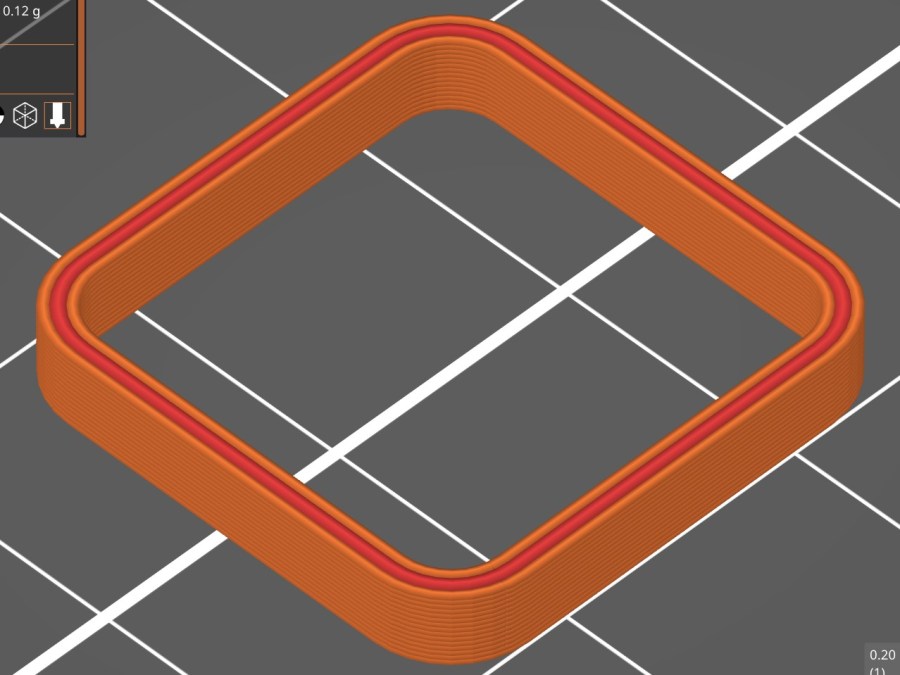

Set up a square with walls three threads thick:

With PrusaSlicer set to produce 0.45 mm thread widths, the walls should measure exactly 1.35 mm = 3×0.45 mm thick:

- PETG = 1.30 mm (1.29 to 1.30)

- PETG-CF = 1.40 mm (1.37 to 1.40)

While I think you could tweak the EM for both materials, it’s unlikely to make any practical difference on typical objects.

So it looks like a slightly lower temperature with 1.0 EM will produce good outside dimensions for the carbon fiber filaments, while models with precise thin sections will require careful tuning.

Comments

4 responses to “Prusa MK4 vs. PETG-CF”

Keep in mind that CF is abrasive to a brass nozzle. You should use a steel nozzle for it.

Got the super-whoopie Obxidian hardened nozzle:

https://www.prusa3d.com/product/prusa-nozzle-obxidian-0-4-mm-2/

Which came in a separate package and added nearly a week onto the delivery because … customs?

Apparently carbon fiber cuts the lifetime of a brass nozzle to hours, which was enough to get my attention. I should probably stock up on spare steel nozzles, even though I have plenty of ordinary PETG to use up.

[…] gray bearing is PETG-CF and has maybe 1 mm of axial play, which agrees with my original observation that an Extrusion Multiplier of 1.0 results in slightly overstuffed carbon fiber parts. It’s […]

[…] in gray PETG-CF (carbon fiber) with Extrusion Multiplier = 1.0 based on the Pill Tube tests and and slightly lower temperatures based on the temperature tower. It definitely looks overstuffed […]