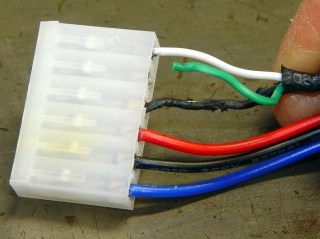

At one point along the way, the Control Panel reported the ABP temperature as 1024 °C, which seemed excessive. A bit of poking around revealed this situation on the ABP connector:

The connector just barely clears the top of the X axis homing switch board and the loose wires tended to rub on the top of the cable connector. I’d been meaning to fix that for a while, but now I had a real reason.

A bit of soldering and some self-vulcanizing tape later:

Also: notice the discoloration on the connector shell surrounding the Black wire? That’s the contact leading back to the MOSFET from the platform heater: a single pin carrying far more than its rated current. The shell around the contact on the Red wire (which carries the same current) isn’t discolored, which suggests the Black connector is a bit loose / poorly crimped / whatever. It looked OK to me, so I left it alone.

While I had the cable on the bench, I added a set of those right-angle pins to eliminate the risk of loose wire ends getting into the wrong places.

Comments

3 responses to “ABP Connector Chafing”

When you’re working with crimp pins do you crimp-and-solder or just crimp? It seems like there’s a tradeoff: soldering means they never come loose but makes the wire much more likely to break if it’s flexed, and I’m having trouble figuring out how to judge that tradeoff.

If the truth be known, I don’t have crimpers for all possible pins, so I generally solder the wire and mash the tabs out of the way.

For this one, I soldered the wire atop the already-crimped connector, slipped some heatshrink over the joint, added the rubber boot, and hoped for the best.

Even crimped joints, as these were, require some strain relief. None of the connectors inside the TOM have any strain relief at all and I’ve been adding it as I rebuild bits & pieces. I built most of the box as instructed to see how it all worked out… now I know.

[…] shell over that pin connecting the MOSFET to the heater has been getting crispier despite my attention, cleaning, and occasional DeoxIT application. Burned-out HBP […]