|

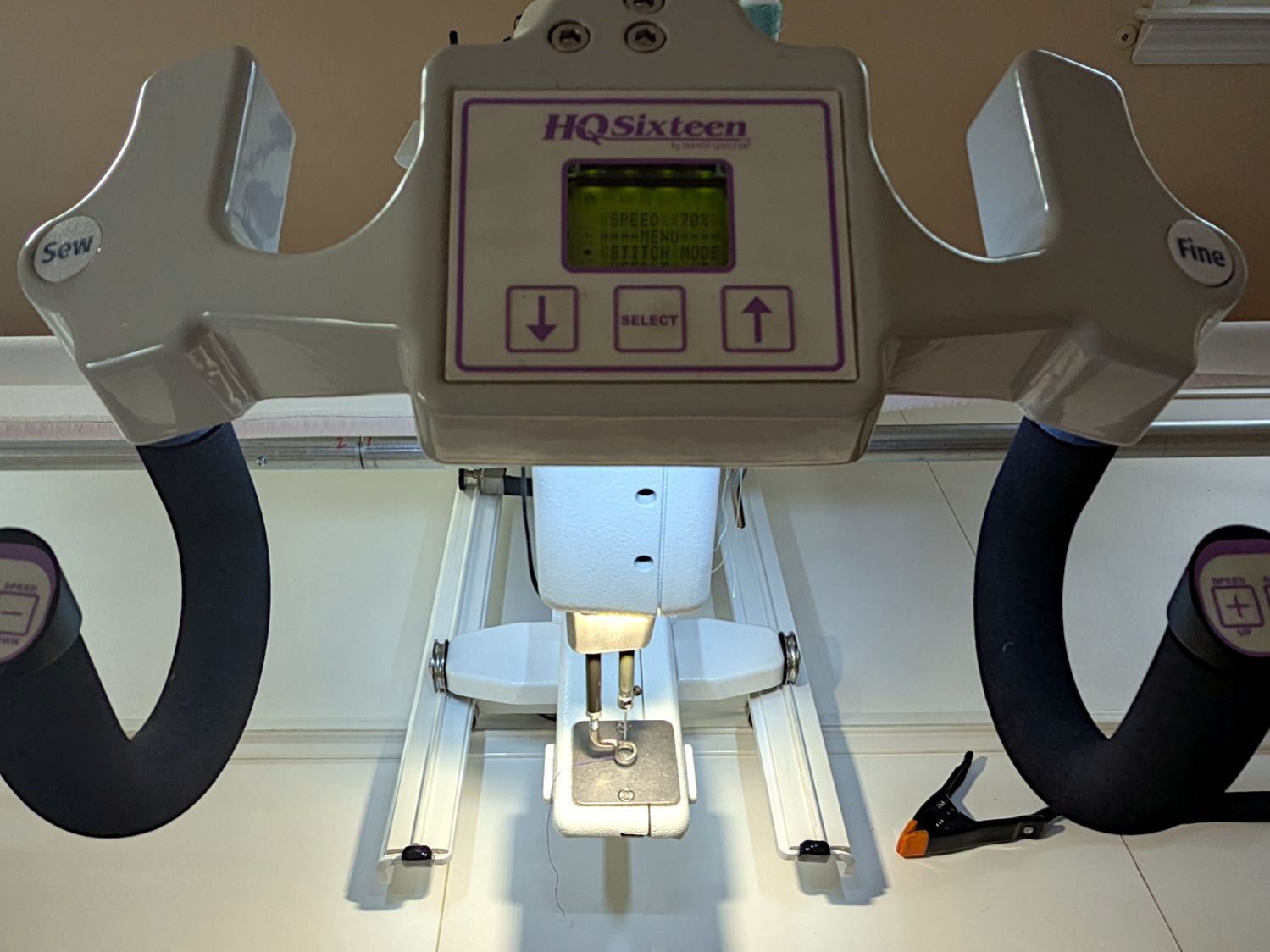

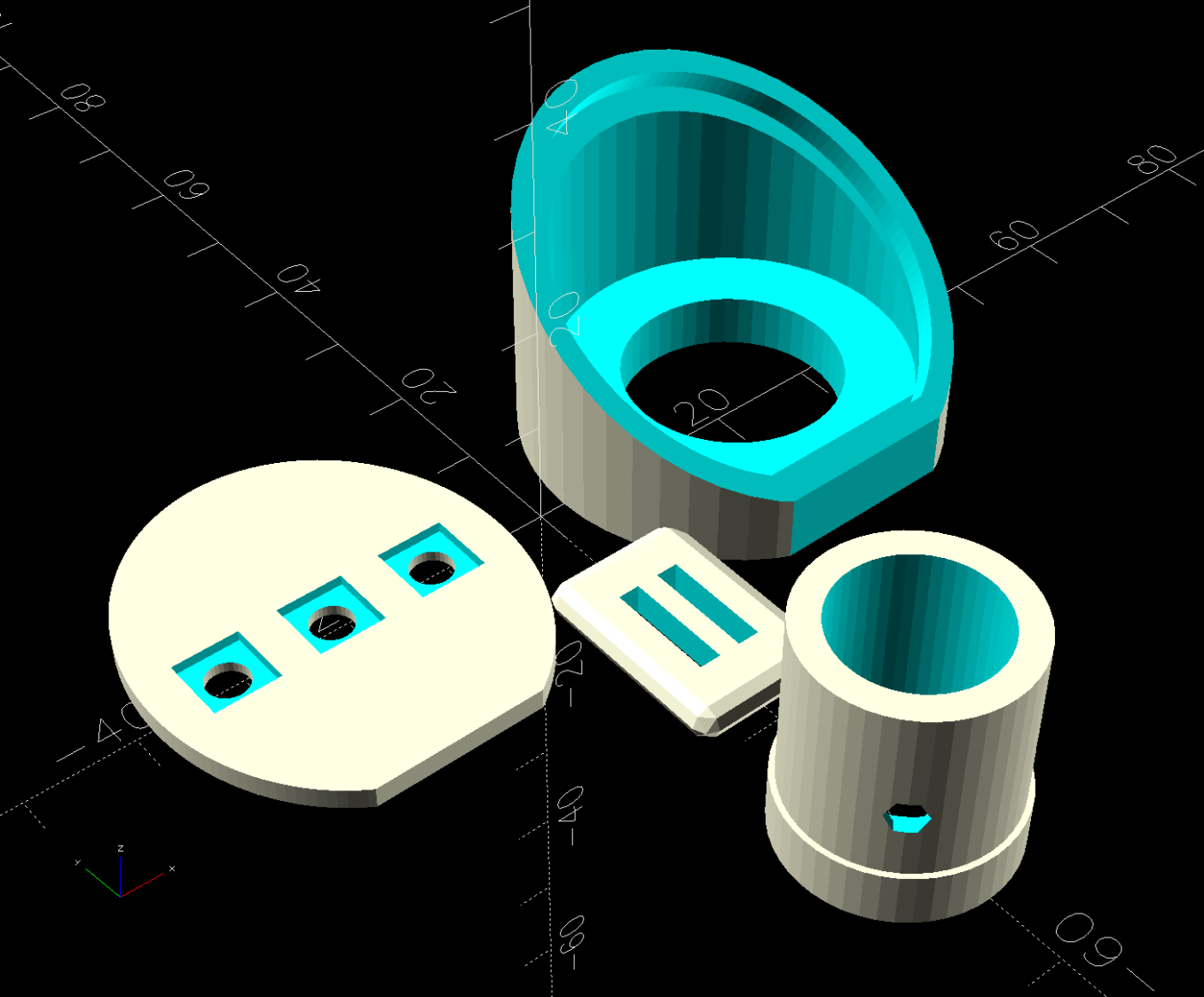

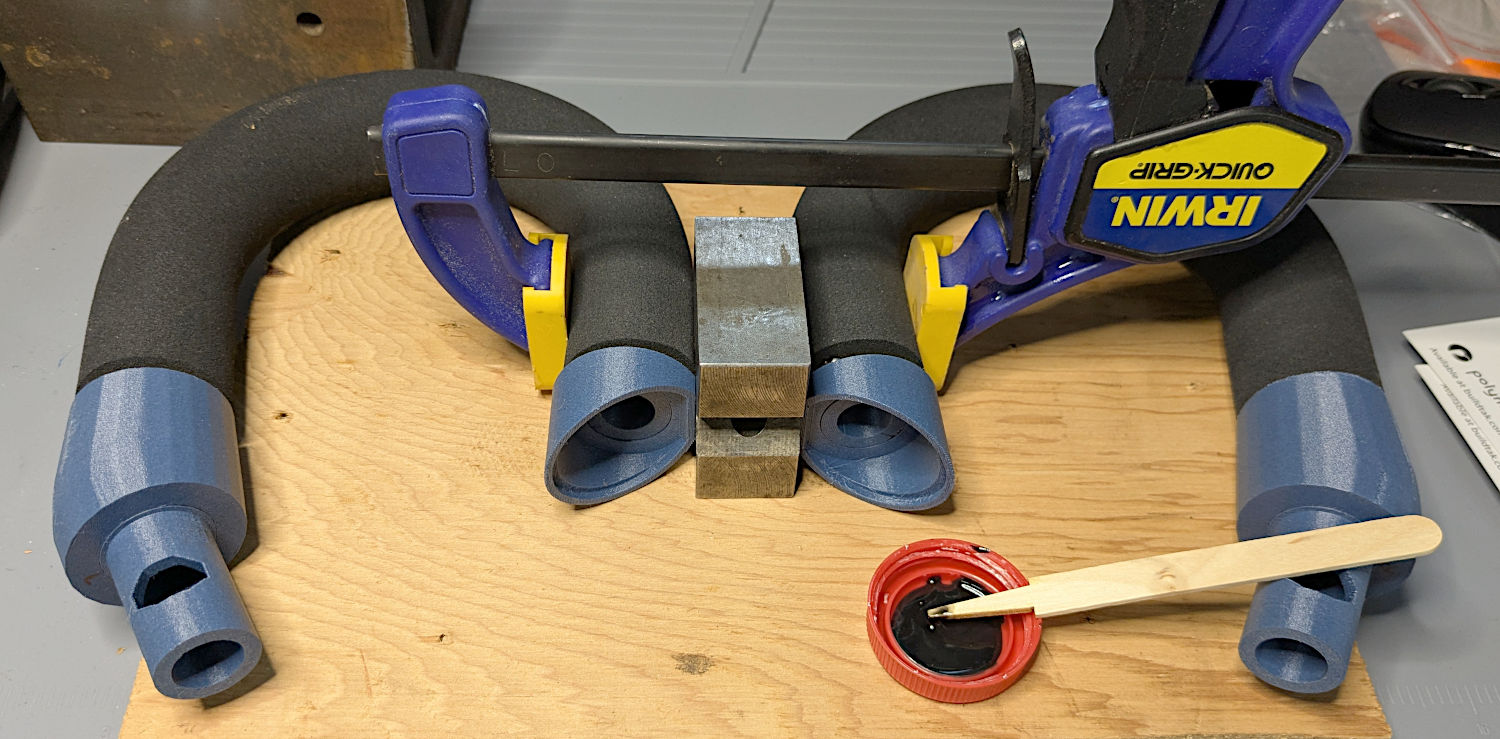

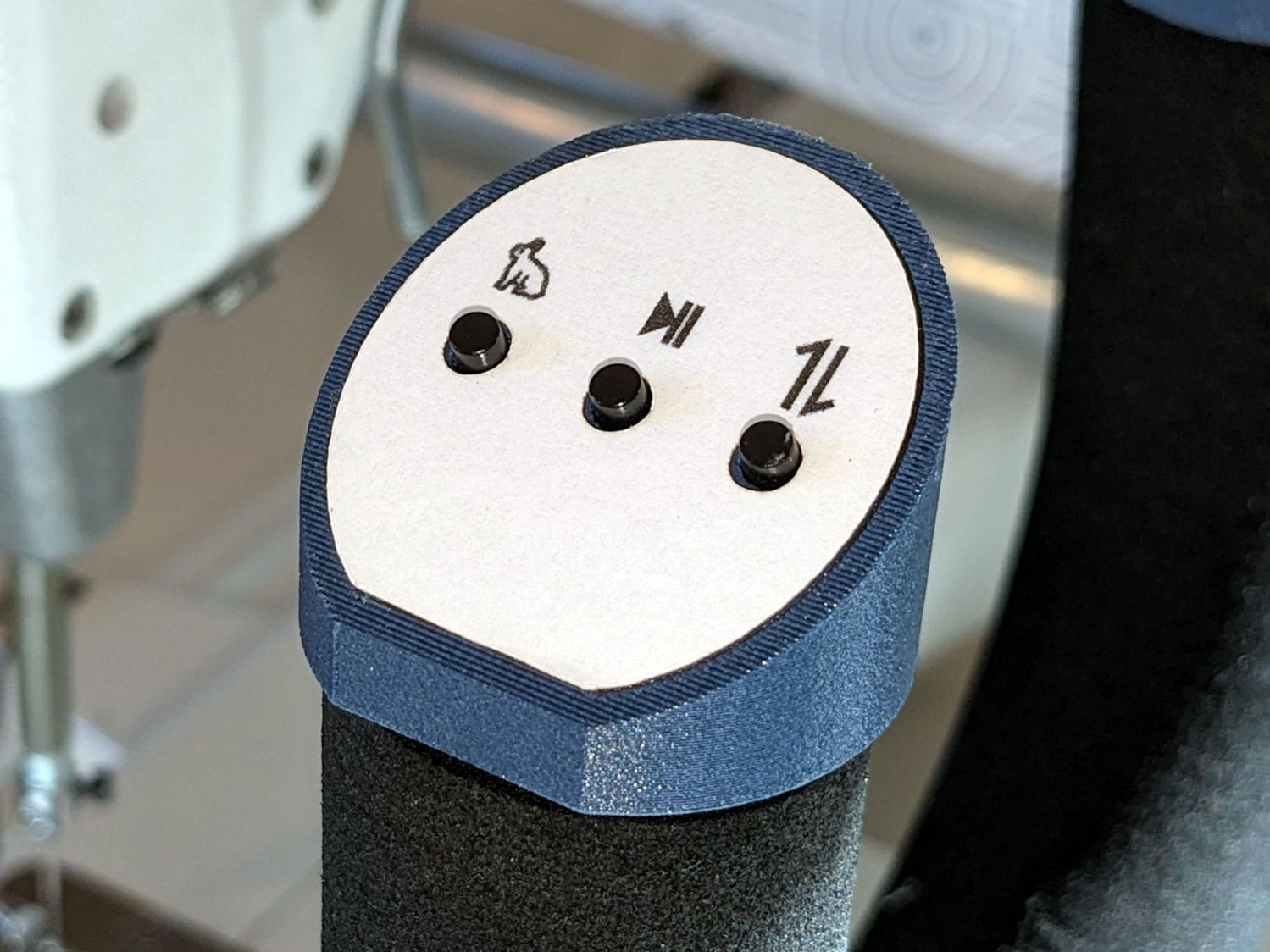

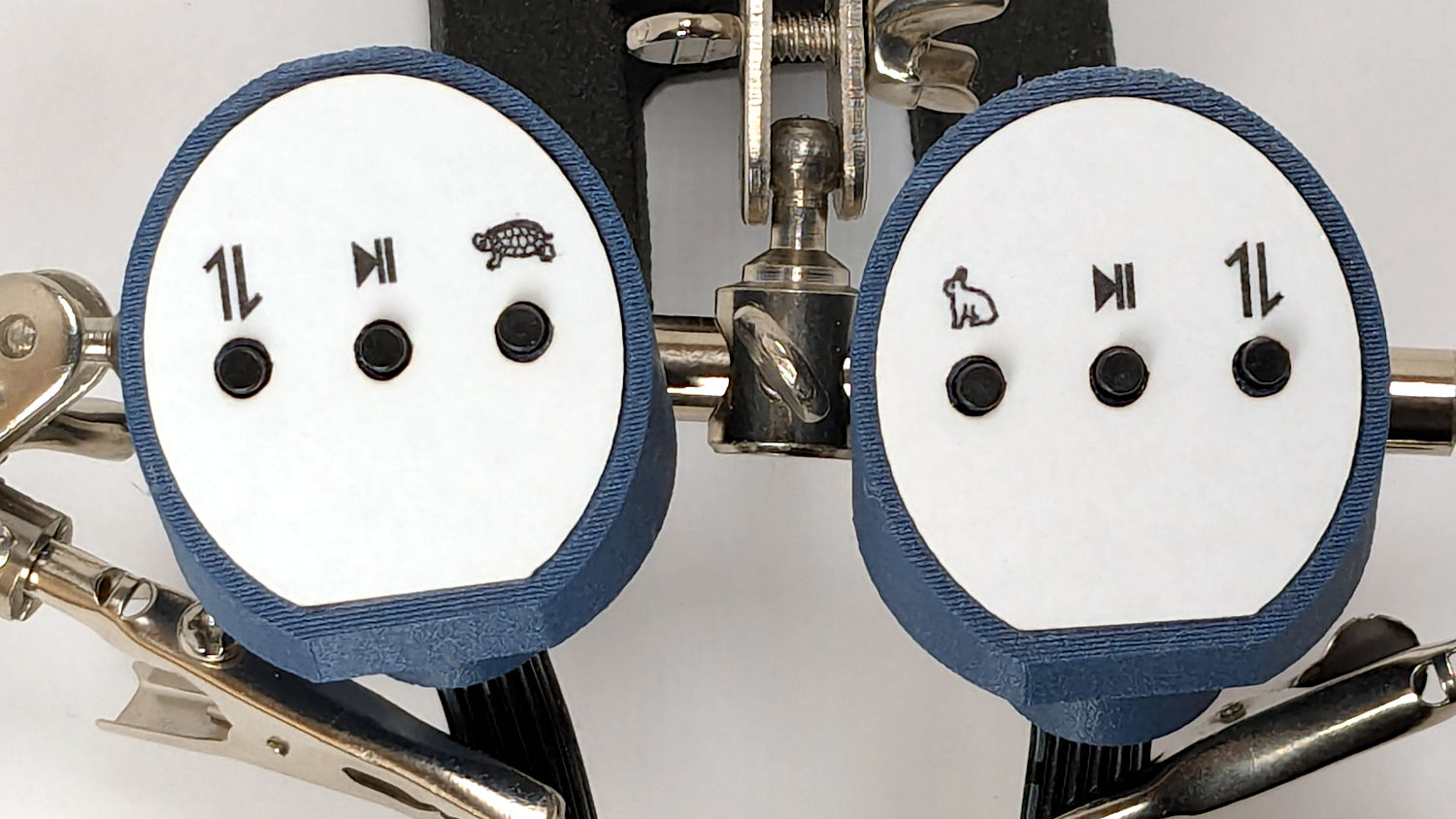

// Handiquilter HQ Sixteen handlebar control button caps |

|

// Ed Nisley – KE4ZNU |

|

// 2025-04-05 |

|

|

|

include <BOSL2/std.scad> |

|

|

|

Layout = "Show"; // [Show,Build,Grip,Body,Face,FaceBack,Plug,CableLock] |

|

|

|

// Angle w.r.t. handlebar |

|

FaceAngle = 30; // [10:45] |

|

|

|

// Separation in Show display |

|

Gap = 5; // [0:20] |

|

|

|

/* [Hidden] */ |

|

|

|

HoleWindage = 0.2; |

|

Protrusion = 0.1; |

|

NumSides = 2*3*4; |

|

|

|

WallThick = 3.0; |

|

|

|

ID = 0; |

|

OD = 1; |

|

LENGTH = 2; |

|

|

|

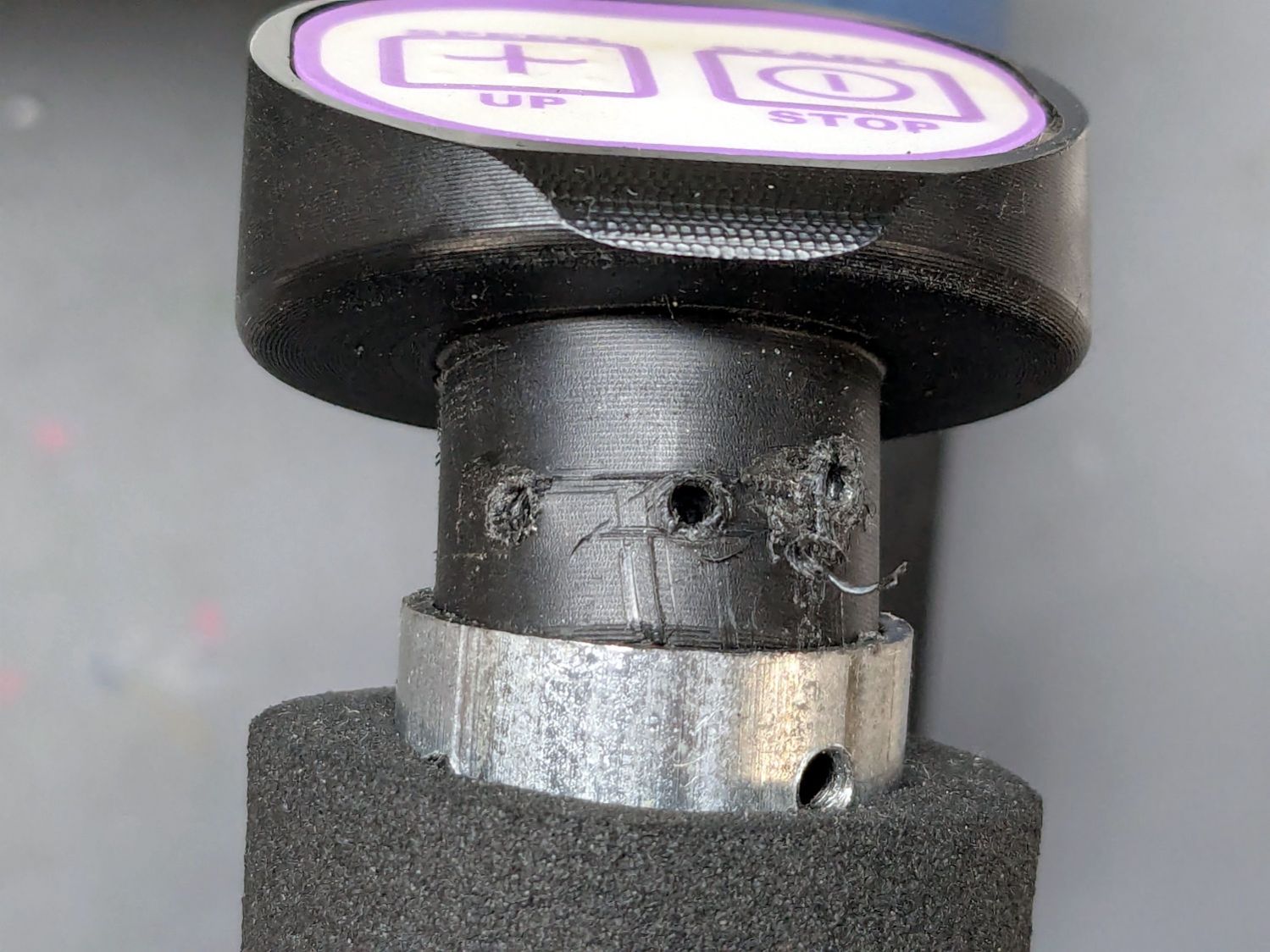

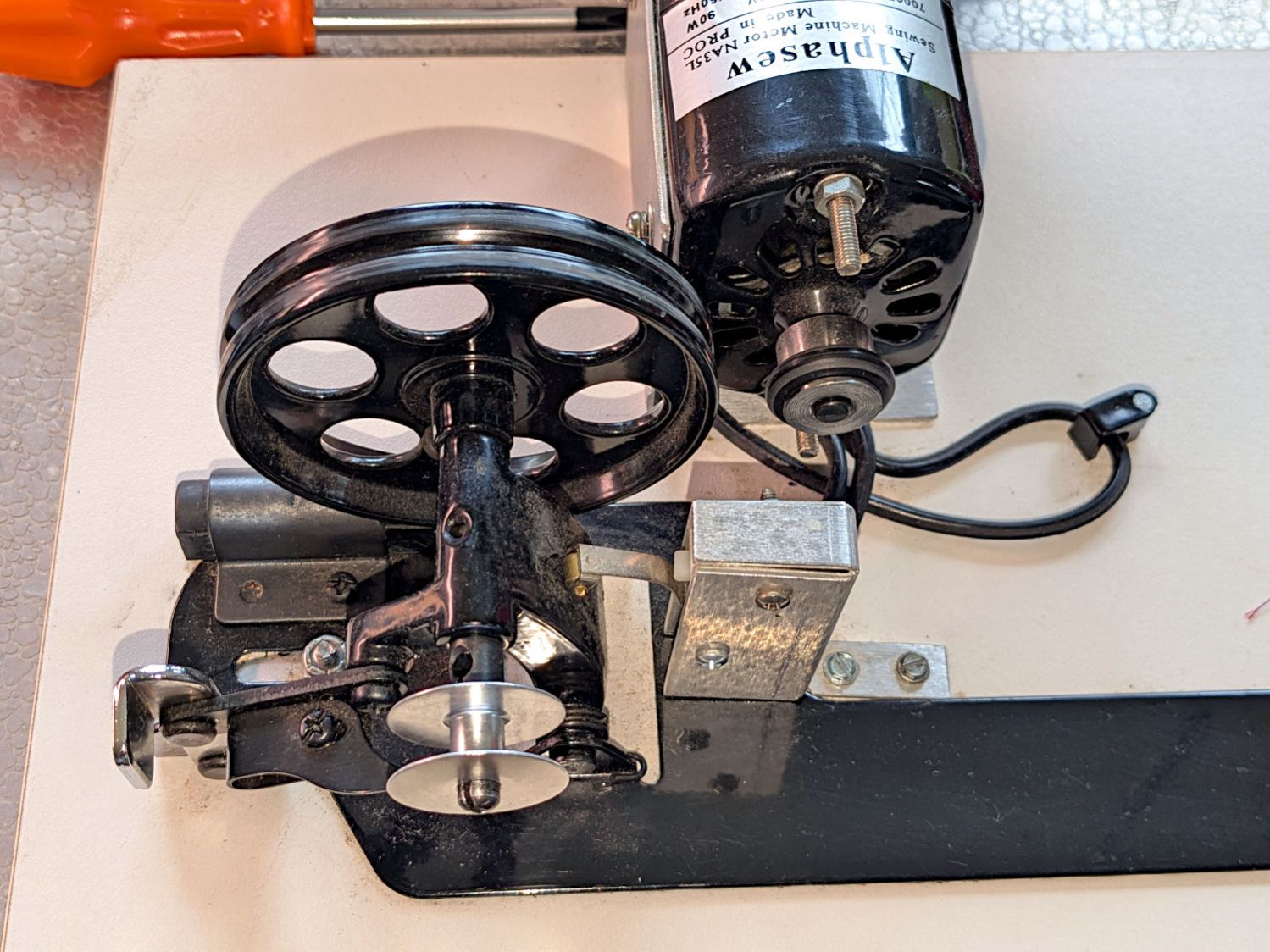

Grip = [19.7,22.4,15.0]; // (7/8)*INCH = 22.2 mm + roughness, LENGTH=OEM insertion depth |

|

GripRadius = Grip[OD]/2; |

|

|

|

FoamOD = 34.0; // handlebar foam |

|

FoamRadius = FoamOD/2; |

|

|

|

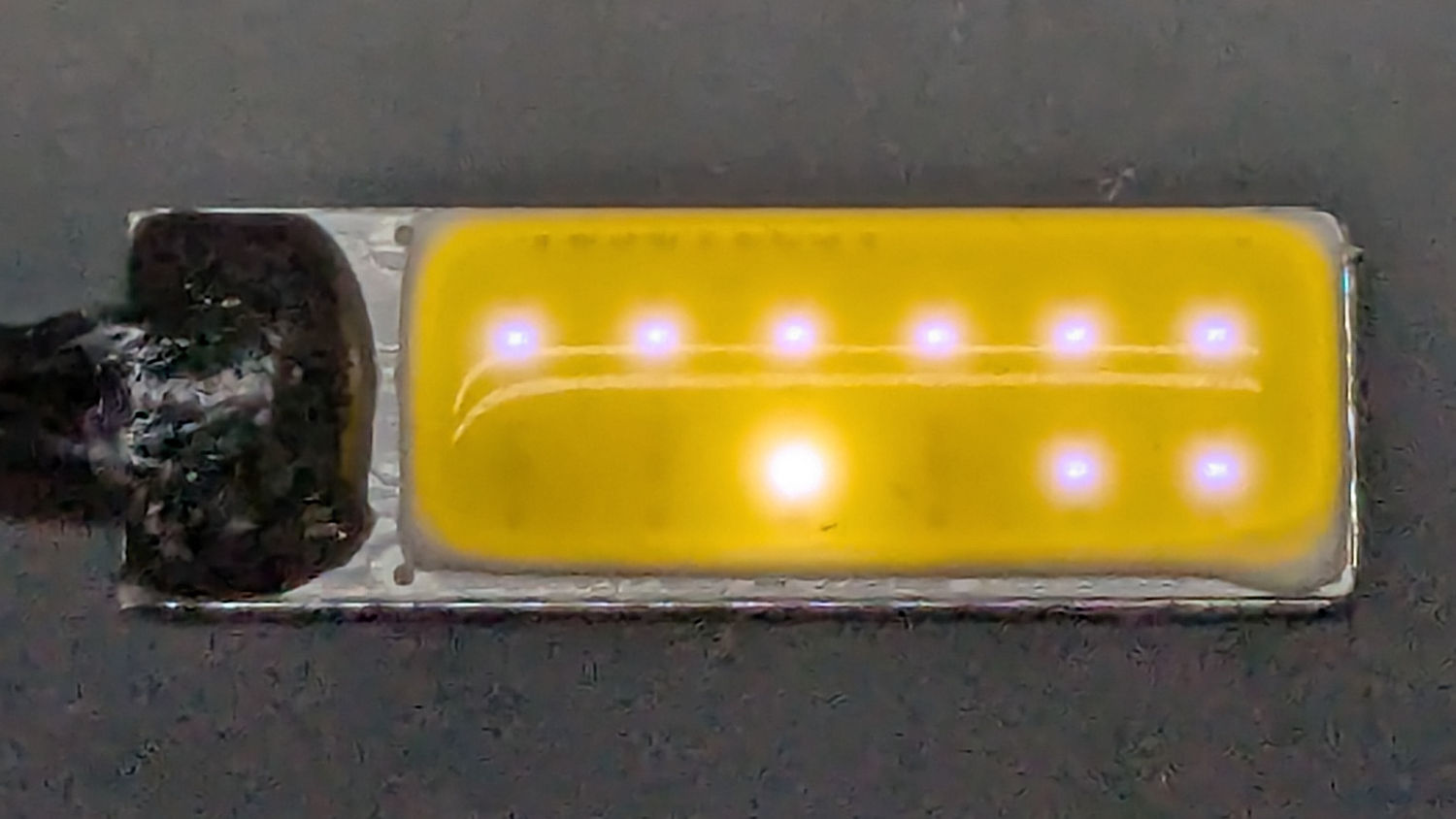

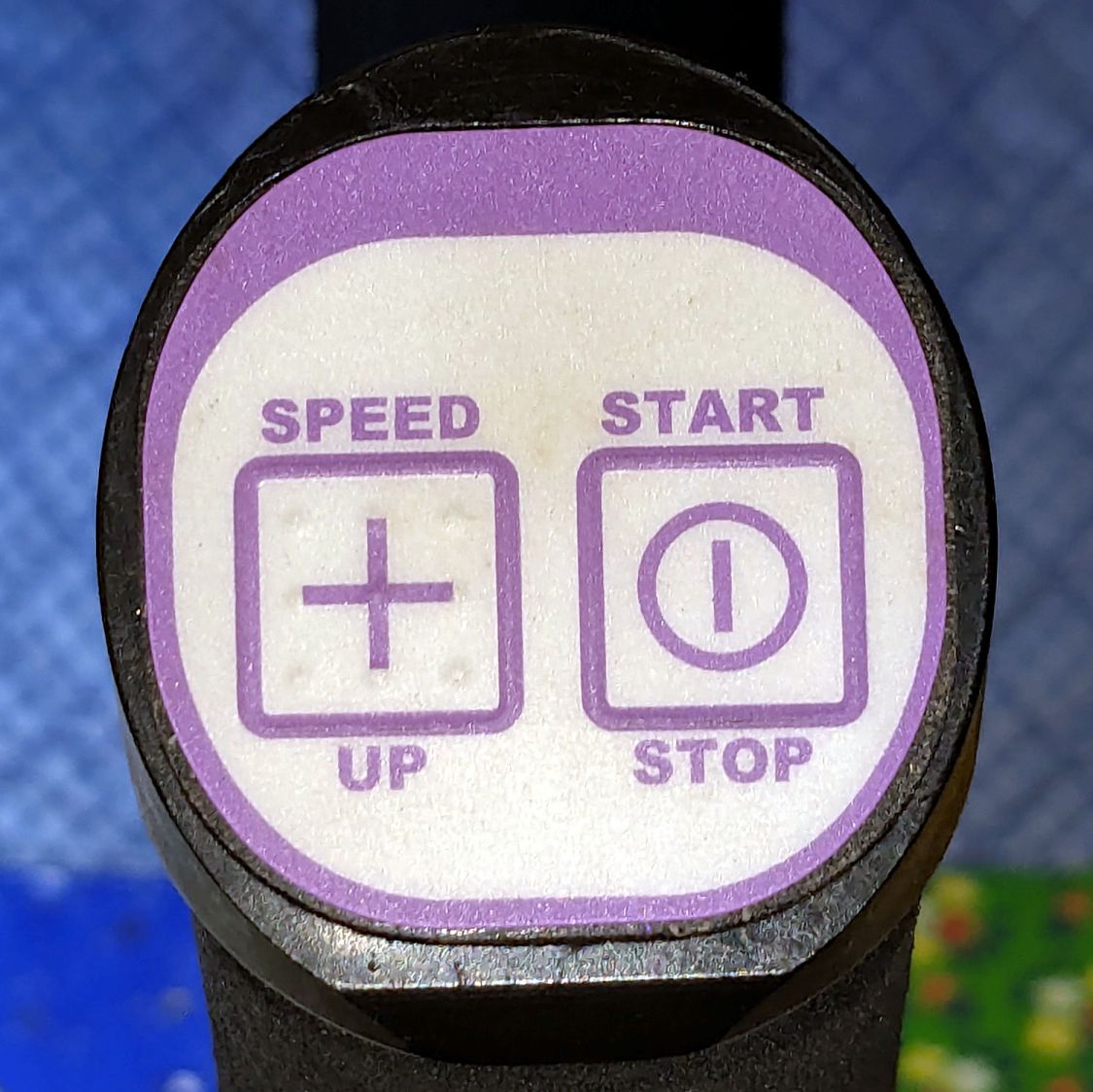

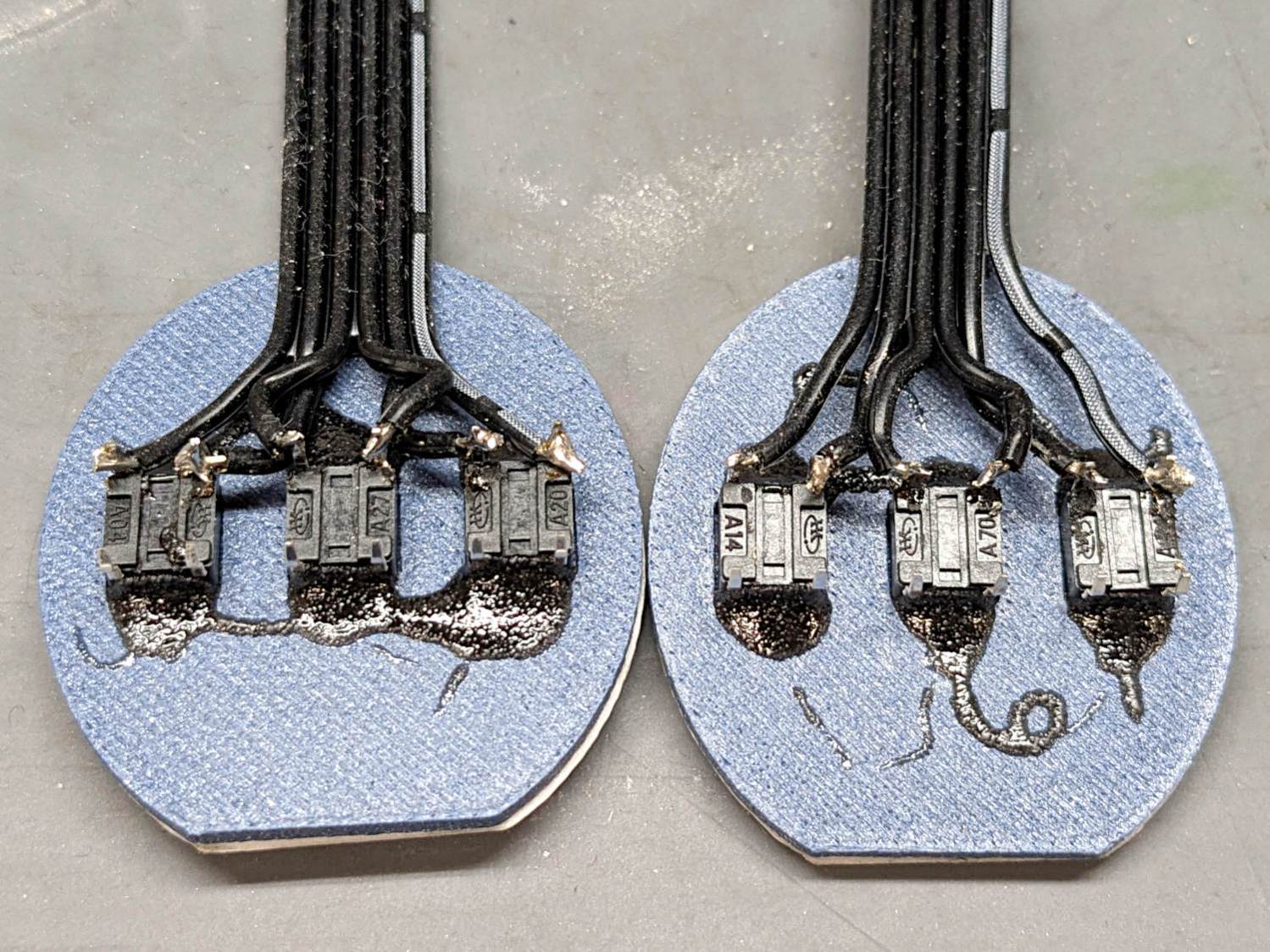

SwitchBody = [6.3,6.3,4.0]; // does not include SMD leads |

|

SwitchStemOD = 3.5 + 2*HoleWindage; |

|

SwitchOC = 10.0; // center-to-center switch spacing |

|

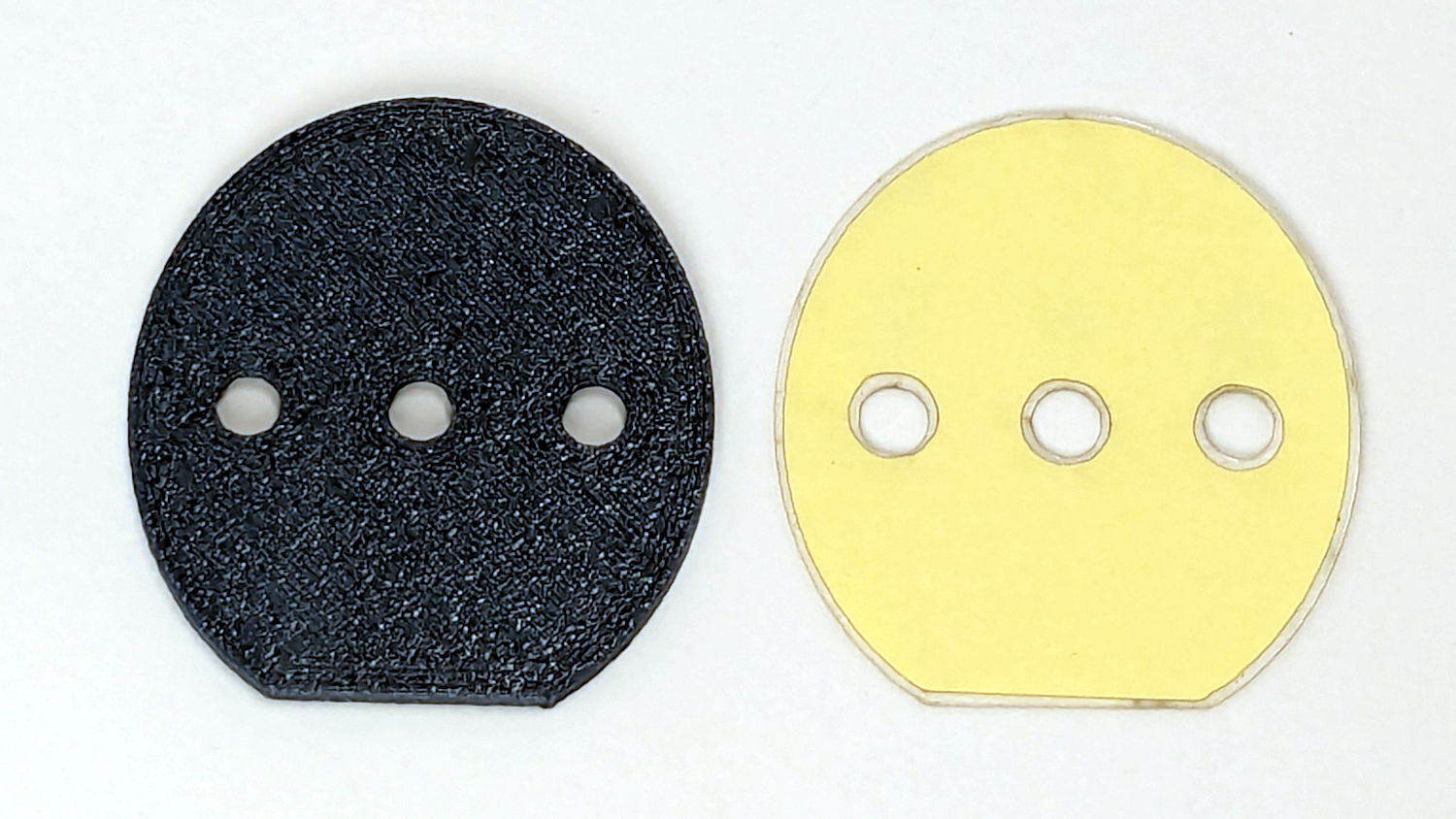

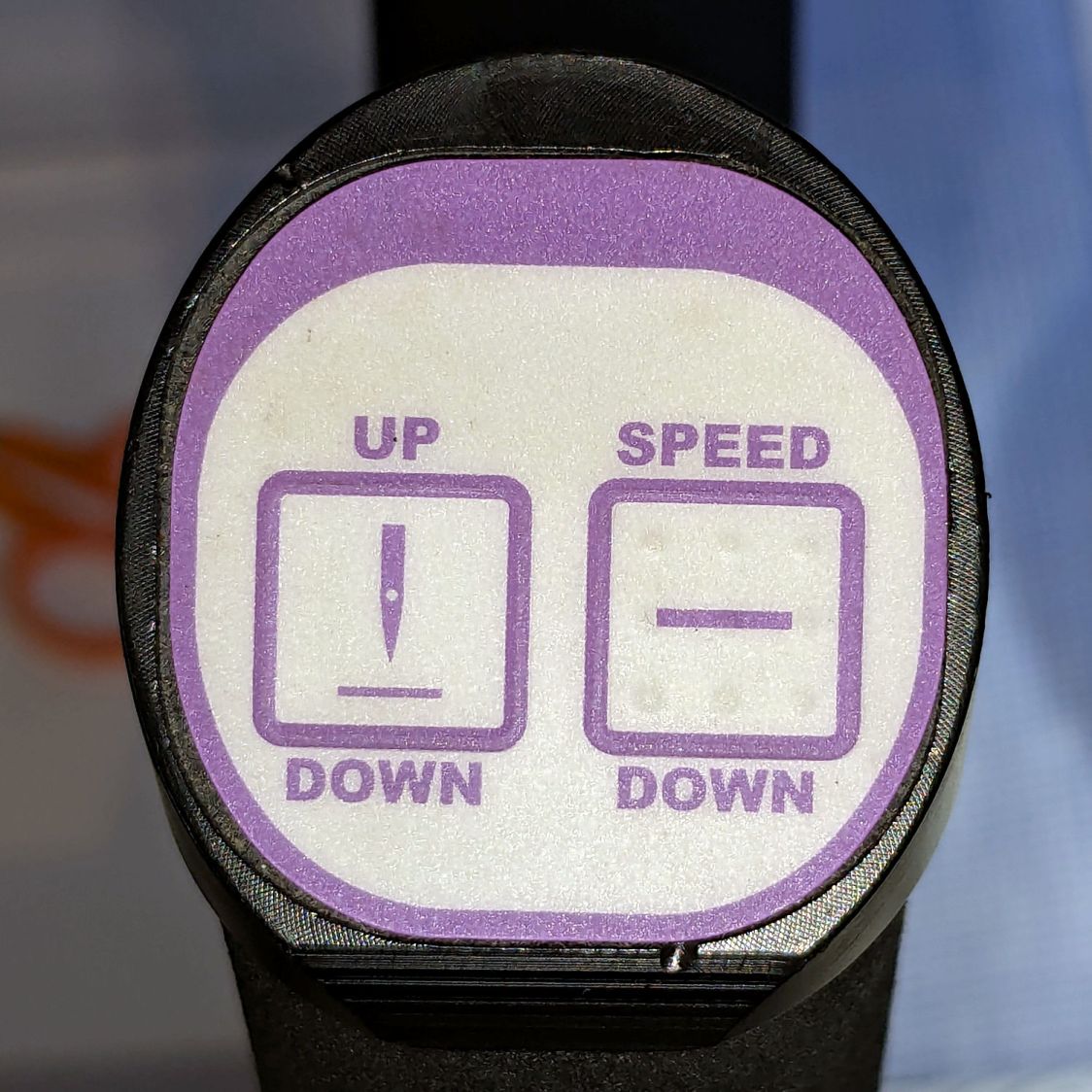

LabelThick = 0.5; // laminated overlay |

|

|

|

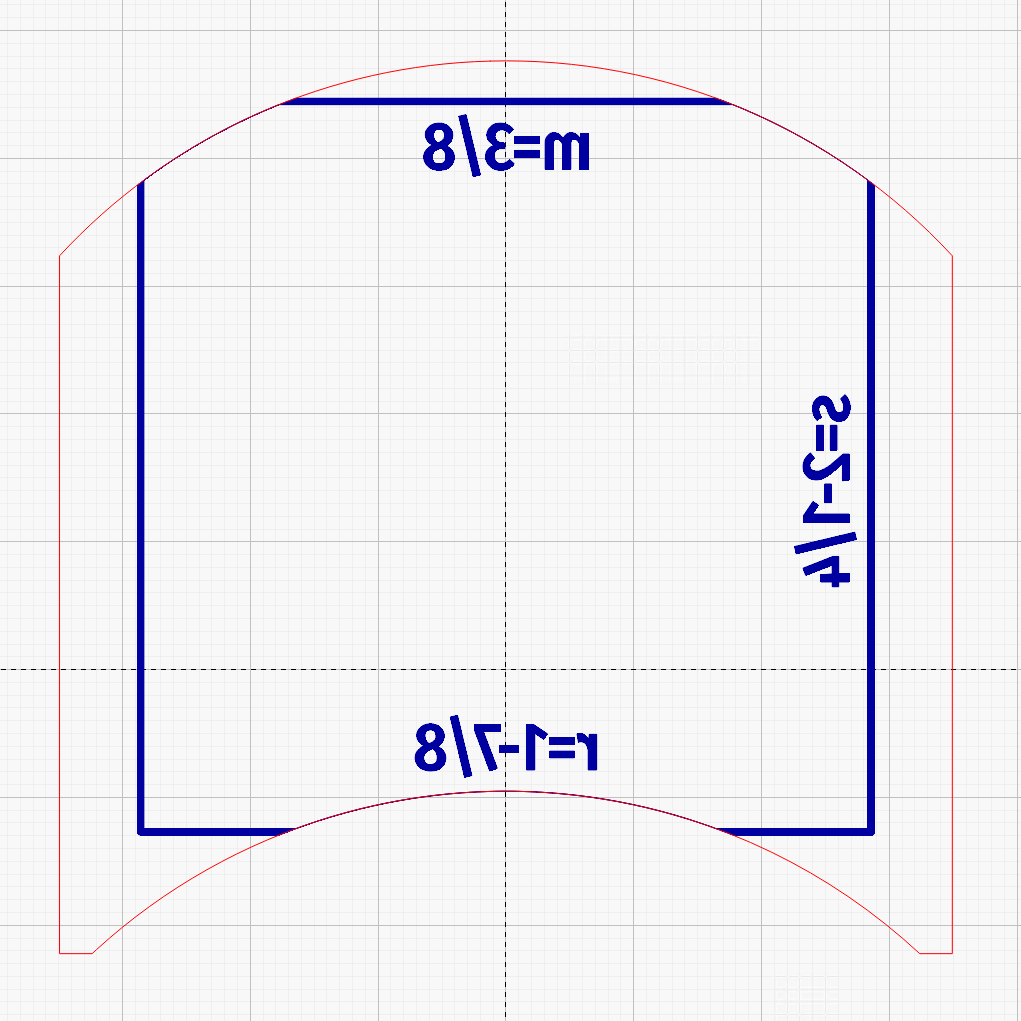

FaceRim = 2.0; // rim around faceplate |

|

FaceThick = 2.0; // … plate thickness |

|

FaceDepth = FaceThick + LabelThick; // inset allowing for faceplate label |

|

|

|

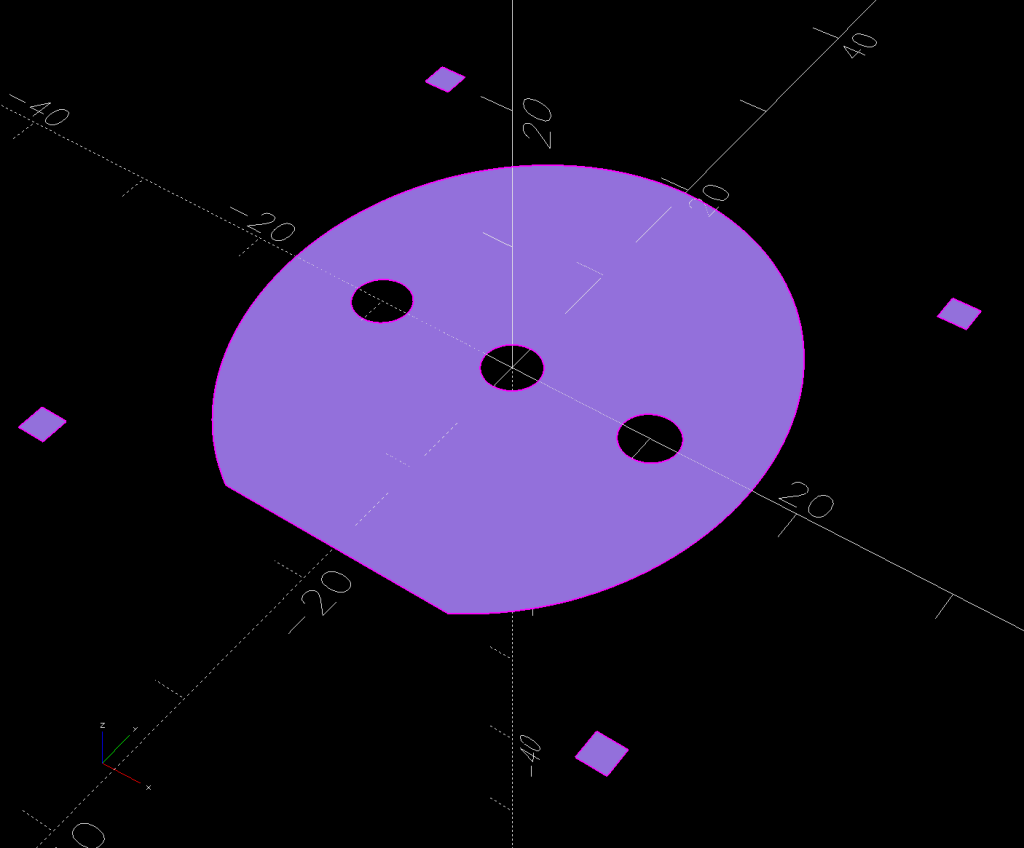

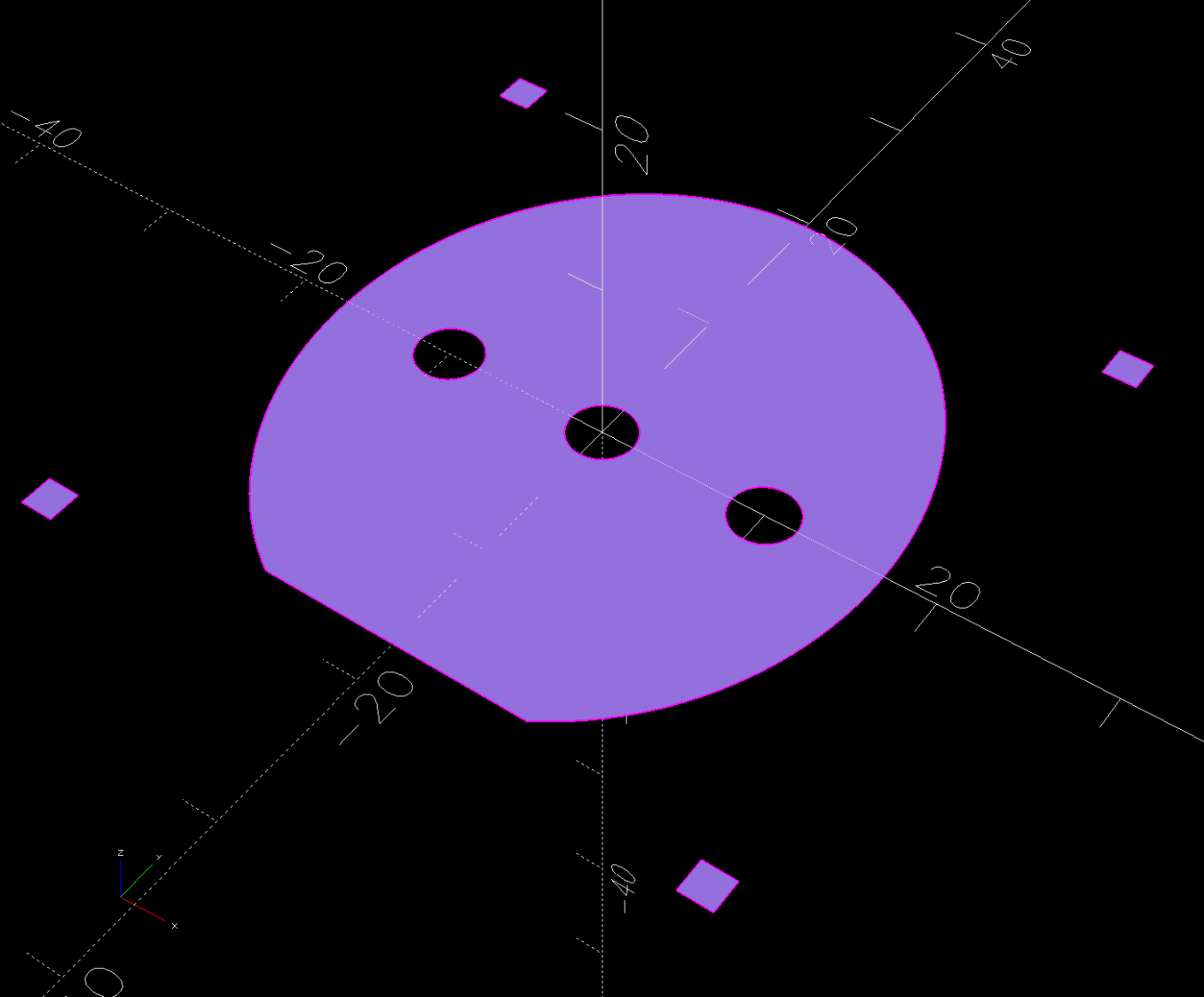

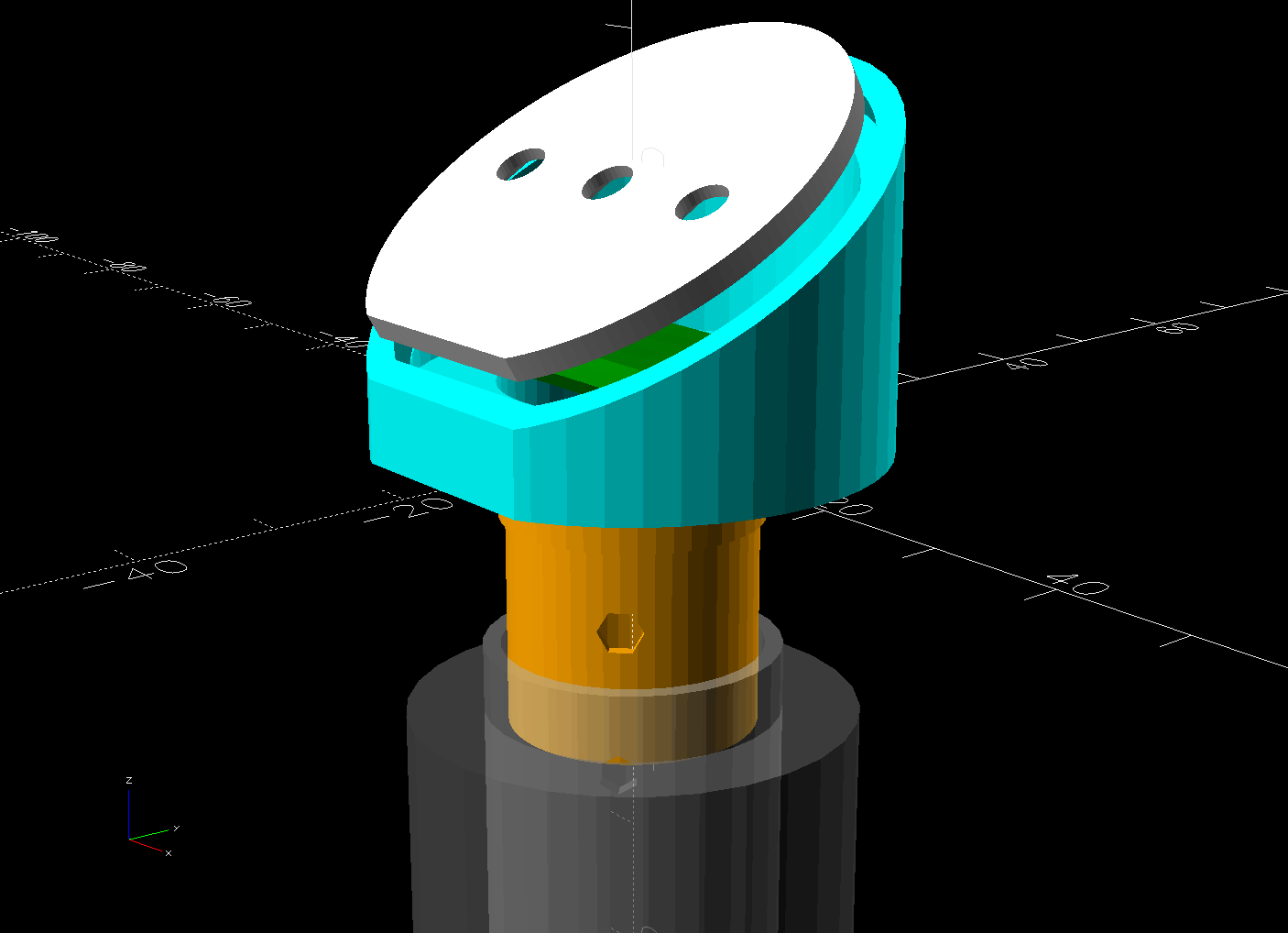

CapOD = 38.0; // overall cap diameter |

|

CapTrim = FoamRadius; // flat trim on front |

|

CapBase = 5.0; // bottom thickness |

|

Cap = [FoamOD – FaceRim,CapOD,CapBase + CapOD*tan(FaceAngle)]; |

|

echo(Cap=Cap); |

|

|

|

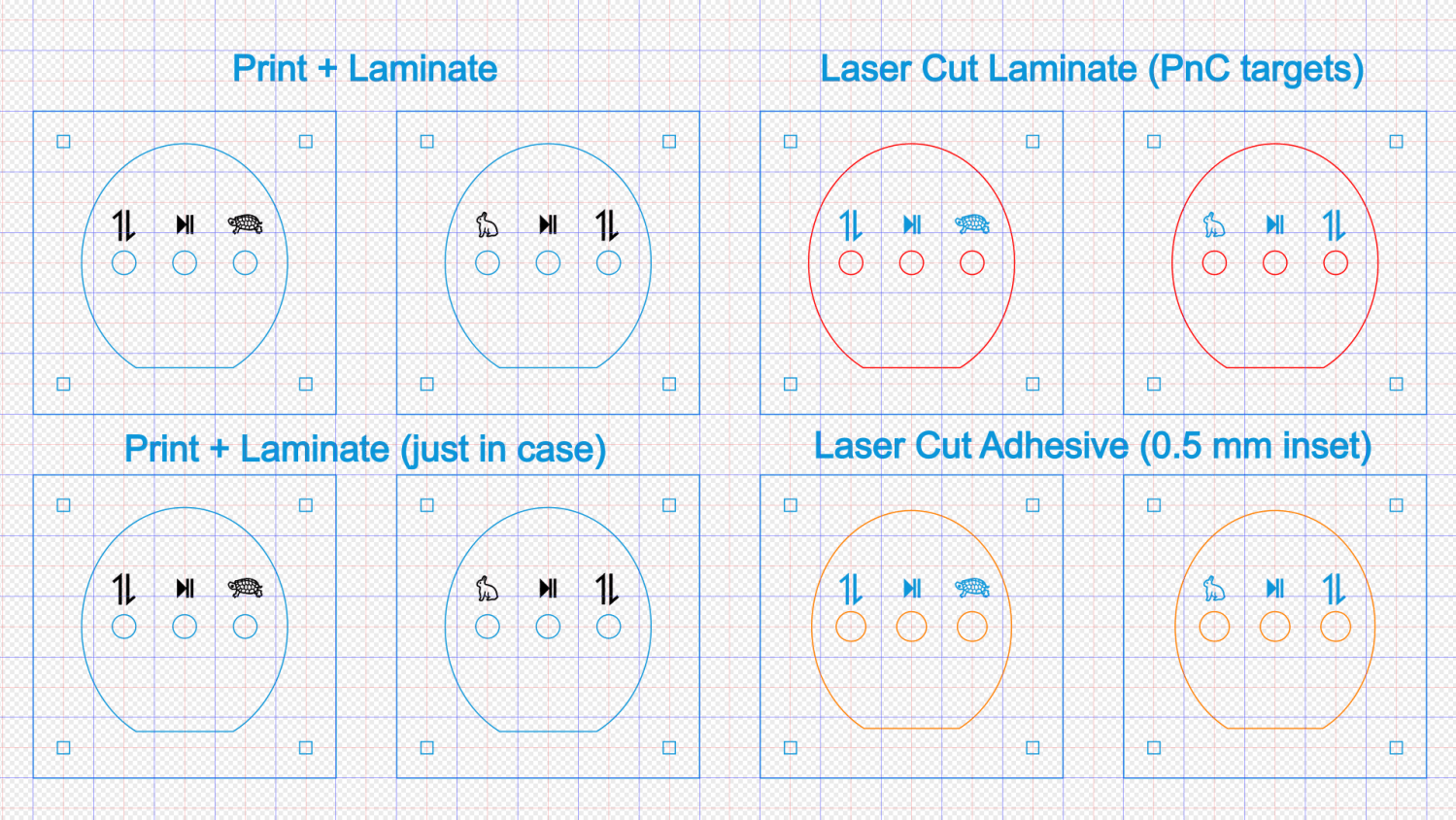

TargetSize = 4.0; // laser alignment targets |

|

TargetsOC = [40.0,40.0]; |

|

|

|

Cable = [10.0,2.0,WallThick]; // aperture for cable lock |

|

|

|

ScrewAngles = [-45,45]; // mounting screws |

|

Screw = [2.0,3.0,7.0]; // OEM = sheet metal screw |

|

ScrewOffset = 6.0; // from top of grip tube |

|

|

|

SquareNut = [3.0,5.5,2.3 + 0.4]; // M3 square nut OD = side, LENGTH + inset allowance |

|

NutInset = GripRadius – sqrt(pow(GripRadius,2) – pow(SquareNut[OD],2)/4); |

|

|

|

PlugOA = [(Grip[ID] – 2*WallThick),(Grip[ID] – 1.0),(CapBase + ScrewOffset + 10.0)]; |

|

echo(PlugOA=PlugOA); |

|

|

|

//———- |

|

// Define objects |

|

|

|

//—– |

|

// Handlebar tube |

|

|

|

module GripTube() { |

|

|

|

difference() { |

|

tube(3*Grip[LENGTH],GripRadius,Grip[ID]/2,anchor=TOP); |

|

for (a = ScrewAngles) { |

|

down(ScrewOffset) zrot(a-90) |

|

right(GripRadius) |

|

yrot(90) cylinder(d=Screw[OD],h=Screw[LENGTH],center=true,$fn=6); |

|

|

|

} |

|

} |

|

} |

|

|

|

//—– |

|

// SVG outline of faceplate for laser cuttery |

|

|

|

module FaceShape(Holes=true,Targets=false) { |

|

|

|

difference() { |

|

|

|

scale([1,1/cos(FaceAngle)]) |

|

difference() { |

|

circle(d=(Cap[OD] – 2*FaceRim),$fn=144); |

|

fwd(CapTrim – FaceRim) |

|

square(Cap[OD],anchor=BACK); |

|

} |

|

|

|

if (Holes) |

|

for (i=[-1:1]) // arrange switch stem holes |

|

right(i*SwitchOC) |

|

zrot(180/8) circle(d=SwitchStemOD,$fn=32); |

|

|

|

} |

|

|

|

if (Targets) |

|

for (i = [-1,1], j = [-1,1]) |

|

translate([i*TargetsOC.x/2,j*TargetsOC.y/2]) |

|

square(2.0,center=true); |

|

} |

|

|

|

//—– |

|

// Faceplate backing sheet |

|

// Switch bodies indented into bottom, so flip to build |

|

|

|

module FacePlate(Thick=FaceThick,Holes=true) { |

|

|

|

difference() { |

|

linear_extrude(height=Thick,convexity=5) |

|

FaceShape(Holes); |

|

up(SwitchBody.z/4) |

|

for (i = [-1:1]) |

|

right(i*SwitchOC) |

|

cube(SwitchBody,anchor=TOP); |

|

} |

|

} |

|

|

|

|

|

//—– |

|

// Cap body |

|

|

|

module CapBody() { |

|

|

|

$fn=48; |

|

|

|

up(CapBase + (Cap[OD]/2)*tan(FaceAngle)) xrot(FaceAngle) |

|

difference() { |

|

xrot(-FaceAngle) |

|

down(CapBase + (Cap[OD]/2)*tan(FaceAngle)) |

|

difference() { |

|

cylinder(d=Cap[OD],h=Cap[LENGTH]); |

|

fwd(CapTrim) down(Protrusion) |

|

cube(2*Cap[LENGTH],anchor=BACK+BOTTOM); |

|

up(CapBase) |

|

difference() { |

|

cylinder(d=Cap[ID],h=Cap[LENGTH]); |

|

fwd(CapTrim – 2*FaceRim) |

|

cube(2*Cap[LENGTH],anchor=BACK+BOTTOM); |

|

} |

|

down(Protrusion) |

|

cylinder(d=Grip[ID],h=Cap[LENGTH]); |

|

} |

|

cube(2*Cap[OD],anchor=BOTTOM); |

|

down(FaceDepth) |

|

FacePlate(FaceDepth + Protrusion,Holes=false); |

|

} |

|

|

|

} |

|

|

|

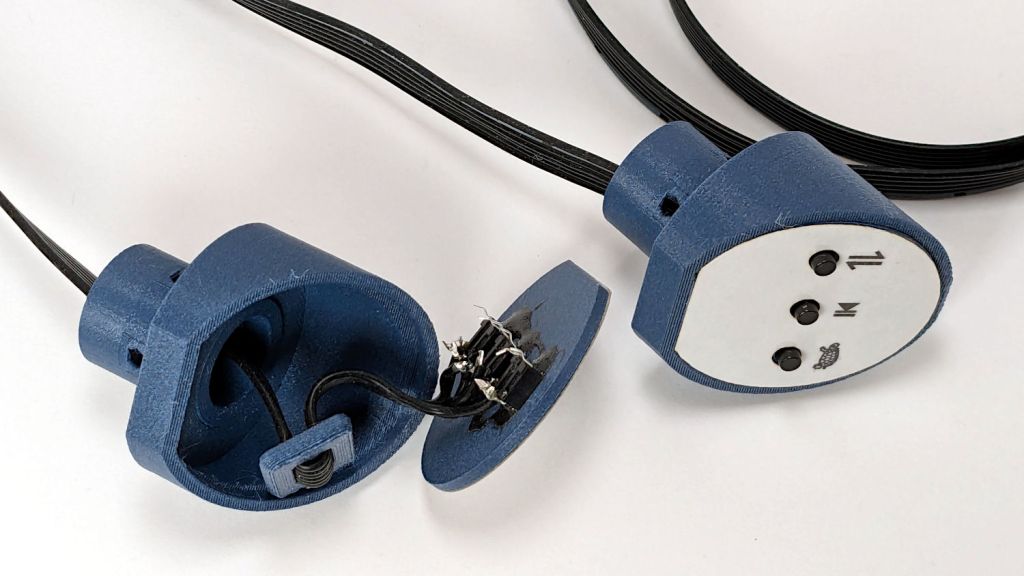

//—– |

|

// Plug going into grip handlebar |

|

|

|

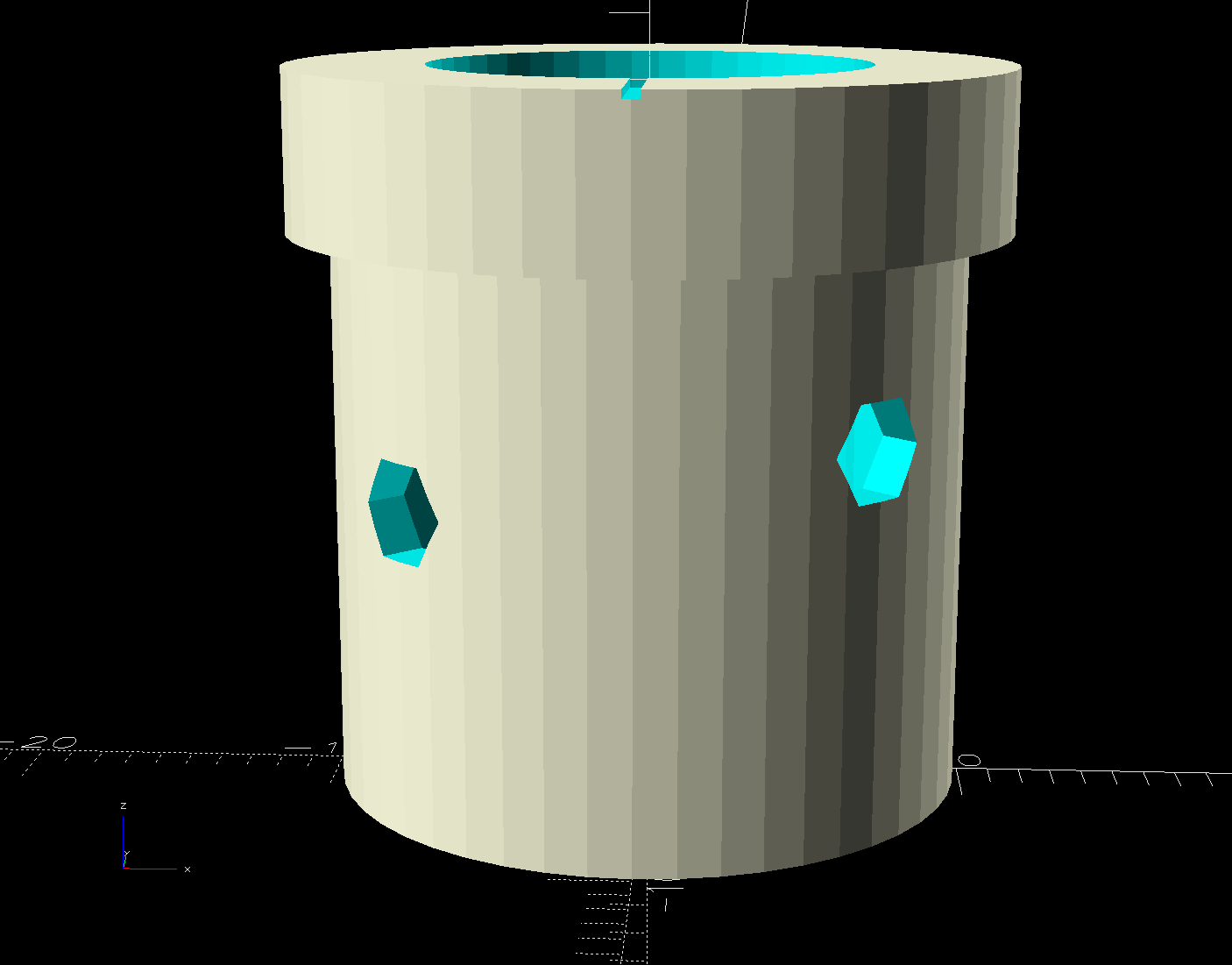

module CapPlug() { |

|

|

|

$fn=48; |

|

|

|

difference() { |

|

tube(PlugOA[LENGTH],id=PlugOA[ID],od=PlugOA[OD],anchor=BOTTOM) |

|

position(TOP) |

|

tube(CapBase,id=PlugOA[ID],od=Grip[ID],anchor=TOP); |

|

for (a = ScrewAngles) |

|

up(PlugOA.z – CapBase – ScrewOffset) zrot(a-90) |

|

right(PlugOA[ID]/2) |

|

yrot(90) { |

|

cube([SquareNut[OD],SquareNut[OD],SquareNut[LENGTH] + NutInset],center=true); |

|

zrot(180/6) |

|

cylinder(d=(SquareNut[ID] + 2*HoleWindage),h=PlugOA[ID],center=true,$fn=6); |

|

} |

|

} |

|

|

|

} |

|

|

|

//—– |

|

// Lock plate for ribbon cable |

|

|

|

module CableLock() { |

|

|

|

difference() { |

|

cuboid([2*Cable.x,PlugOA[ID],WallThick],rounding=WallThick/2,anchor=BOTTOM); |

|

for (j = [-1,1]) |

|

back(j*Cable.y) down(Protrusion) |

|

cube(Cable + [0,0,2*Protrusion],anchor=BOTTOM); |

|

} |

|

|

|

} |

|

|

|

//———- |

|

// Build things |

|

|

|

if (Layout == "Grip") { |

|

color("Silver",0.5) |

|

GripTube(); |

|

} |

|

|

|

if (Layout == "Face") |

|

FaceShape(Targets=true); |

|

|

|

if (Layout == "FaceBack") |

|

FacePlate(); |

|

|

|

if (Layout == "Body") |

|

CapBody(); |

|

|

|

if (Layout == "Plug") |

|

CapPlug(); |

|

|

|

if (Layout == "CableLock") |

|

CableLock(); |

|

|

|

if (Layout == "Show") { |

|

|

|

color("Green") |

|

up(CapBase) |

|

CableLock(); |

|

|

|

color("Orange") |

|

down(Gap) |

|

down(PlugOA[LENGTH] – CapBase) |

|

CapPlug(); |

|

|

|

color("Cyan",(Gap > 4)? 1.0 : 0.2) |

|

CapBody(); |

|

|

|

color("White",(Gap > 4)? 1.0 : 0.5) |

|

up(Gap*cos(FaceAngle)) fwd(Gap*sin(FaceAngle)) |

|

up(CapBase + (Cap[OD]/2)*tan(FaceAngle) – FaceDepth) |

|

back(FaceDepth*sin(FaceAngle)) xrot(FaceAngle) |

|

FacePlate(); |

|

|

|

down(3*Gap) { |

|

color("Silver",0.5) |

|

GripTube(); |

|

|

|

down(Gap) |

|

color("Gray",0.5) |

|

tube(3*Grip[LENGTH],FoamRadius,Grip[OD]/2,anchor=TOP); |

|

} |

|

} |

|

|

|

if (Layout == "Build") { |

|

right((Gap + Cap[OD])/2) |

|

CapBody(); |

|

left((Gap + Cap[OD])/2) |

|

zrot(180) up(FaceThick) xrot(180) |

|

FacePlate(); |

|

fwd(Gap + Cap[OD]) |

|

up(PlugOA[LENGTH]) xrot(180) zrot(180) |

|

CapPlug(); |

|

fwd(Cap[OD]/2) |

|

zrot(90) |

|

CableLock(); |

|

} |