Long years ago, the Bakelite (or some such) lid on our rarely used teapot disintegrated, whereupon I replaced it with an aluminum sheet and metal knob. Admittedly, a metal knob was not the brightest idea I ever had, but it sufficed for a few uses over the intervening decades.

Mary hosted this month’s quilting bee and, after having someone else bring a larger teapot for the occasion, suggested I Make. A. Better. Knob. After a bit of searching, this statue seemed appropriate for the season:

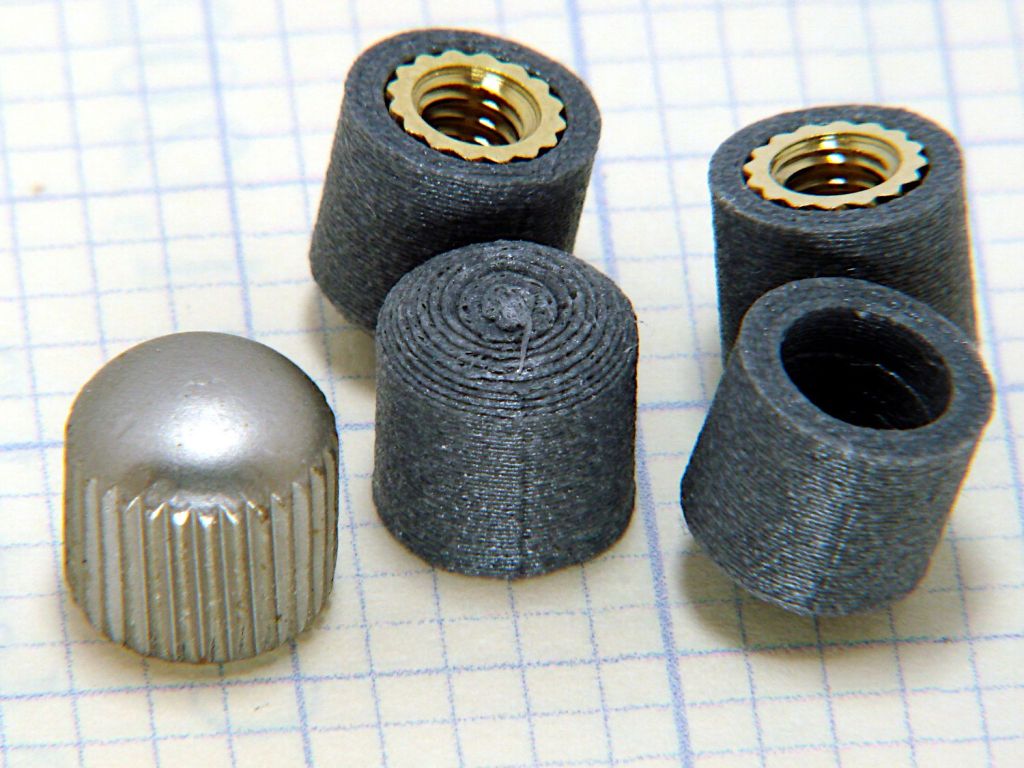

It’s printed with PETG filament that should easily withstand the no-more-than-boiling-water temperatures found atop a teapot.

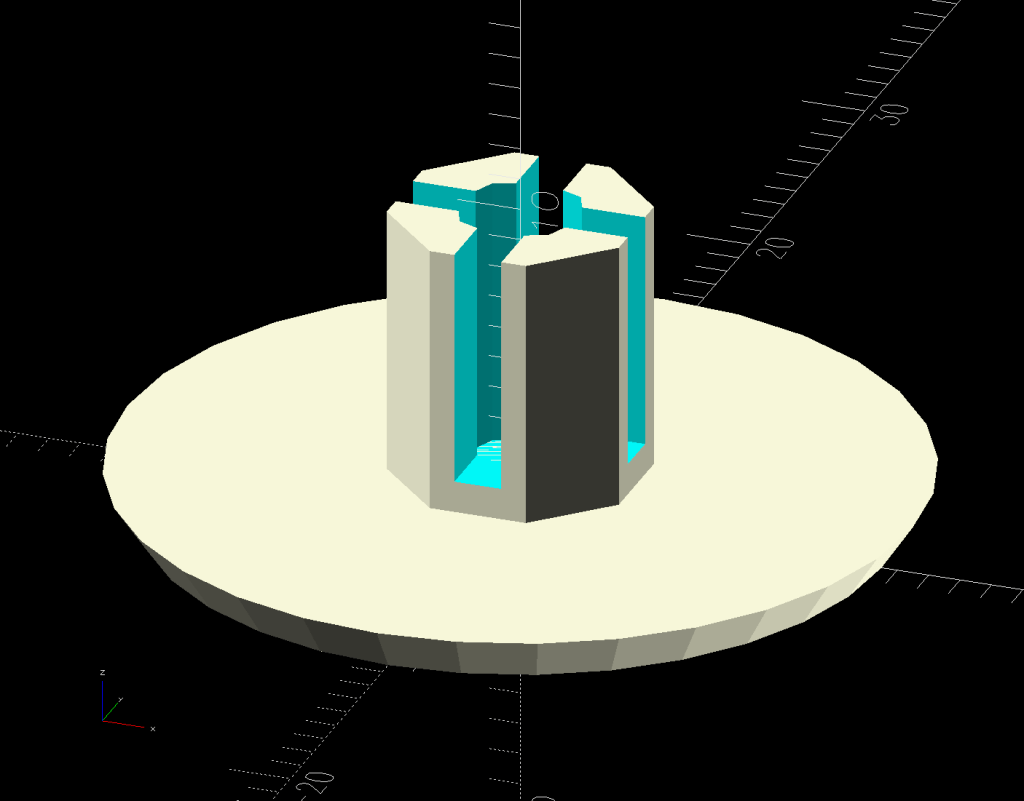

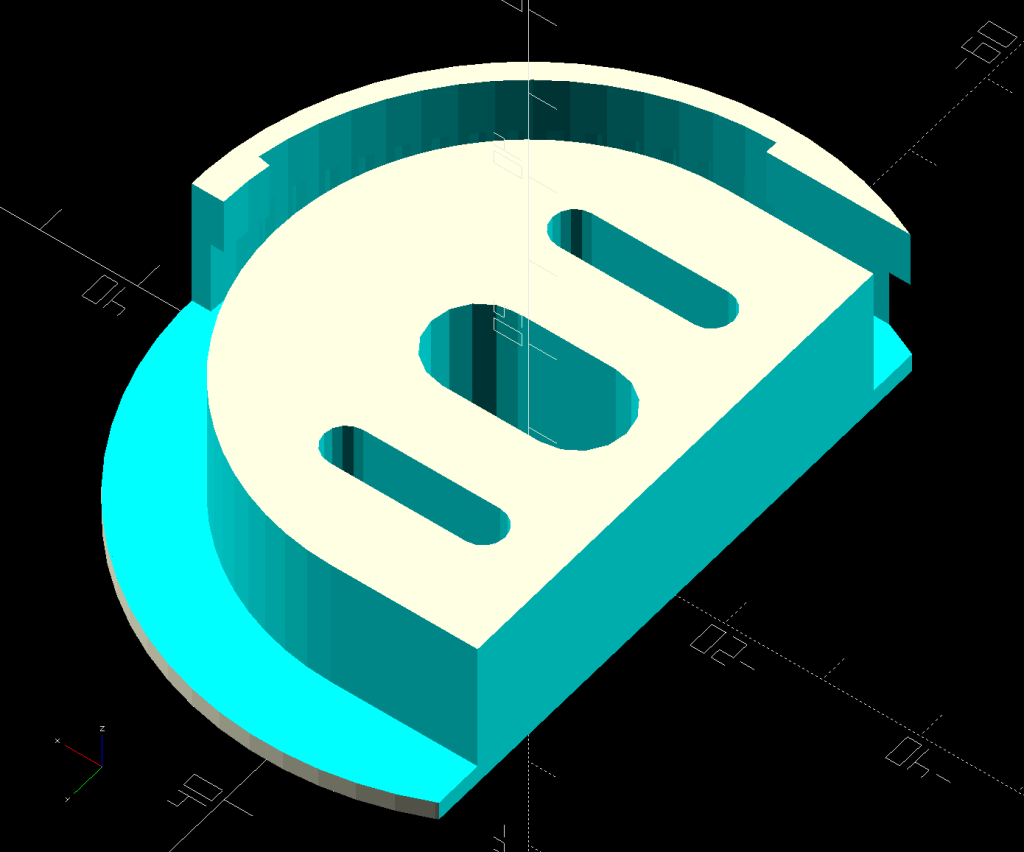

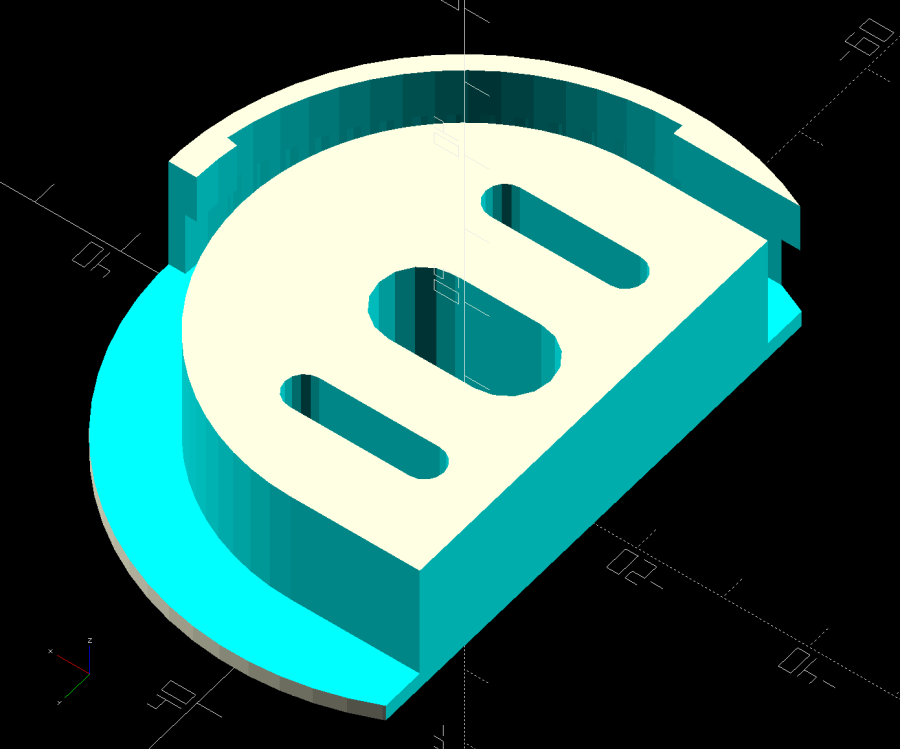

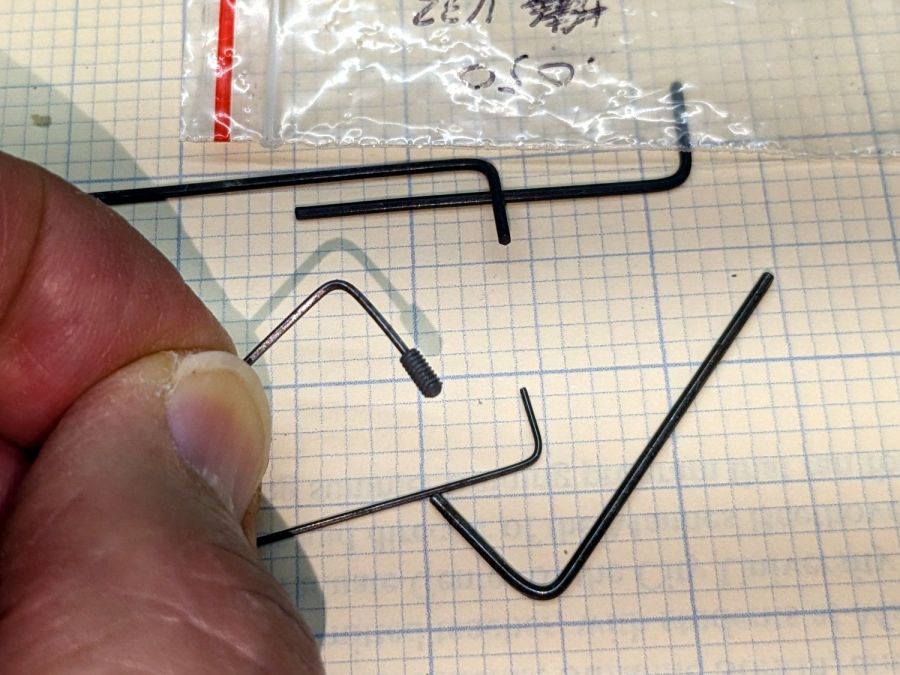

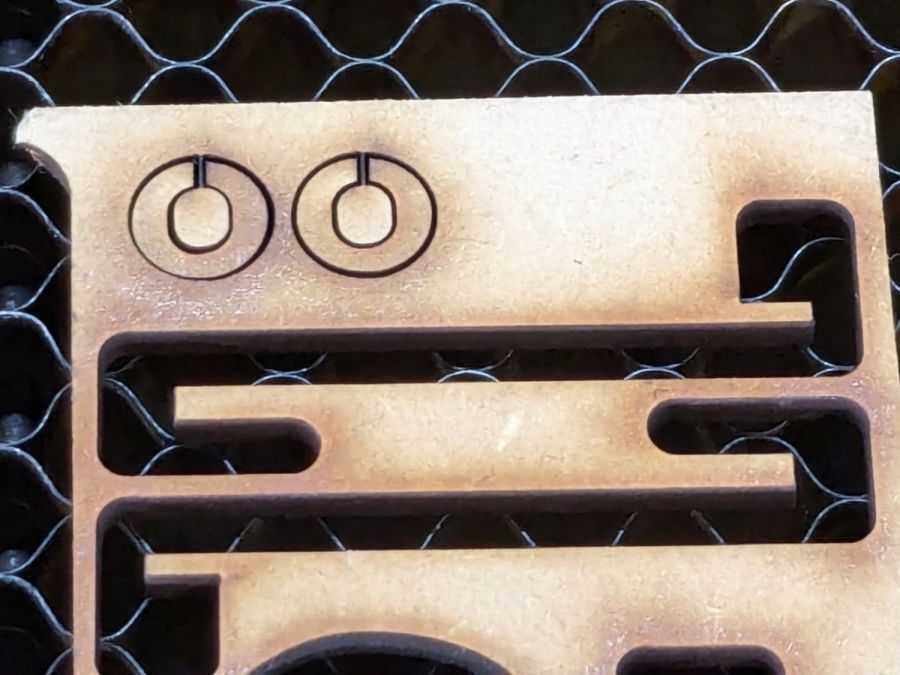

I imported the original model into PrusaSlicer, shrank it to 50 mm tall and simplified the mesh, exported it as an OBJ file, imported it into OpenSCAD, mashed it together with a 1/4-20 threaded_nut from BOSL2, added the finger protector, and got a suitable model:

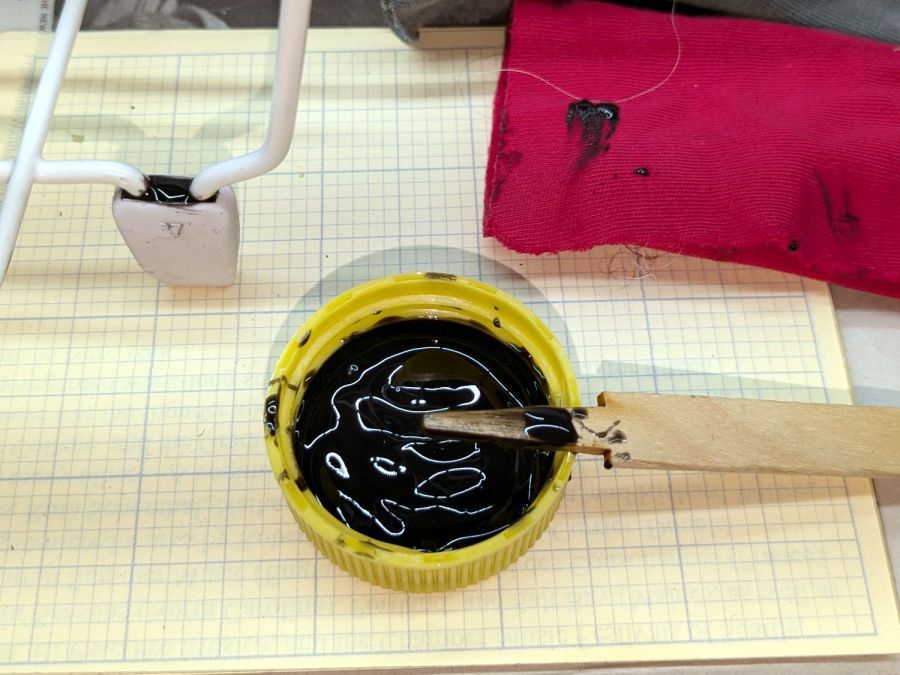

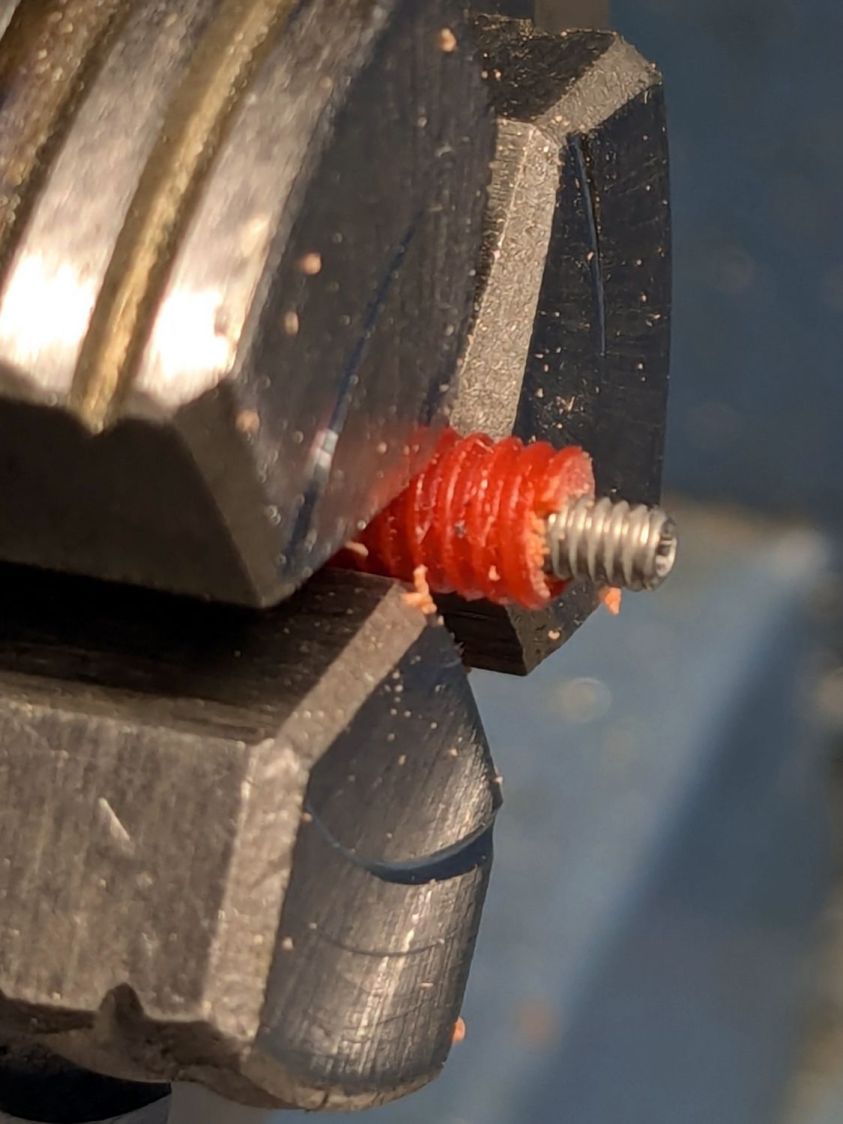

The as-printed threads were a bit snug with $slop=0, but running the screw in with a dot of silicone grease to ease the way worked fine.

I should rebuild the whole lid in PETG-CF sometime.

The OpenSCAD code stitches the parts together:

// Teapot Knob

// Ed Nisley - KE4ZNU

// 2024-10-11

include <BOSL2/std.scad>

include <BOSL2/threading.scad>

StackHeight = 50.0;

ThreadLength = 25.0;

HeatbreakOD = 40.0;

HeatbreakThick = 3.0;

intersection() {

union() {

cylinder(d=HeatbreakOD,h=HeatbreakThick,$fn=2*4*9);

up(HeatbreakThick)

translate([-121,-105]) // totally eyeballometric

import("stackofskulls - 50mm.obj",convexity=10);

}

union() {

threaded_nut(100,INCH/4,ThreadLength,INCH/20, // flat size, root dia, height, pitch

bevel=false,ibevel=false,anchor=BOTTOM);

up(ThreadLength)

cylinder(d=100,h=StackHeight);

}

}