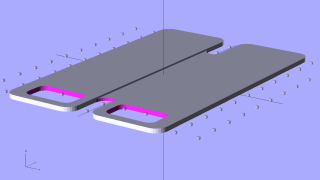

After fixing that old plate, I just had to do this:

Which pretty much fills up the build platform:

And fits perfectly:

It’s printed with 100% infill to produce a solid plastic plate.

In retrospect, I think it’d work better if I put the notch on the bottom side with a bit of support, so that the glass-smooth surface faced the Zire. Maybe next time?

The OpenSCAD source code:

// Protector plate for Zire 71 PDA

// Ed Nisley KE4ZNU - Jan 2012

//-------

//- Extrusion parameters must match reality!

// Print with +0 shells, 3 solid layers, 0.2 infill

ThreadThick = 0.25;

ThreadWidth = 2.0 * ThreadThick;

Protrusion = 0.1; // make holes end cleanly

function IntegerMultiple(Size,Unit) = Unit * ceil(Size / Unit);

function IntegerMultipleMin(Size,Unit) = Unit * floor(Size / Unit);

//-------

// Dimensions

$fn=8*4;

Length = 110;

Width = 73;

Thickness = IntegerMultiple(2.0,ThreadThick);

CornerRadius = 5.0;

NotchLength = 20;

PocketWidth = 22;

PocketLength = 12;

PocketRadius = 3.0;

PocketOffsetX = -1;

PocketOffsetY = 10;

SlotLength = 20;

SlotWidth = IntegerMultiple(8.0,ThreadWidth);

SlotDepth = IntegerMultiple(0.75,ThreadThick);

//-------

module ShowPegGrid(Space = 10.0,Size = 1.0) {

Range = floor(50 / Space);

for (x=[-Range:Range])

for (y=[-Range:Range])

translate([x*Space,y*Space,Size/2])

%cube(Size,center=true);

}

//-------

// Outer section of plate

// with nice rounded edges

module PlateHalf() {

translate([0,0,Thickness/2])

difference() {

minkowski(convexity=3) {

cube([(Width - SlotWidth)/2 - 2*CornerRadius,(Length - 2*CornerRadius),(Thickness - 2*Protrusion)],center=true);

cylinder(r=CornerRadius,h=Protrusion);

}

translate([PocketOffsetX,PocketOffsetY - Length/2,0])

minkowski() {

cube([PocketWidth - 2*PocketRadius,PocketLength - 2*PocketRadius,Thickness],center=true);

cylinder(r=PocketRadius,h=Protrusion);

}

}

}

//-------

ShowPegGrid();

translate([(Width - SlotWidth)/4 + SlotWidth/2,0,0])

PlateHalf();

translate([-(Width - SlotWidth)/4 - SlotWidth/2,0,0])

mirror([1,0,0])

PlateHalf();

difference() {

translate([0,0,(Thickness - SlotDepth)/2])

cube([SlotWidth + 2*Protrusion,Length - 2*SlotLength + SlotWidth,(Thickness - SlotDepth)],center=true);

for (Index=[-1,1])

translate([0,(Index*(Length/2 - SlotLength + SlotWidth/2)),-Protrusion])

cylinder(r=SlotWidth/2,h=Thickness + 2*Protrusion);

}