|

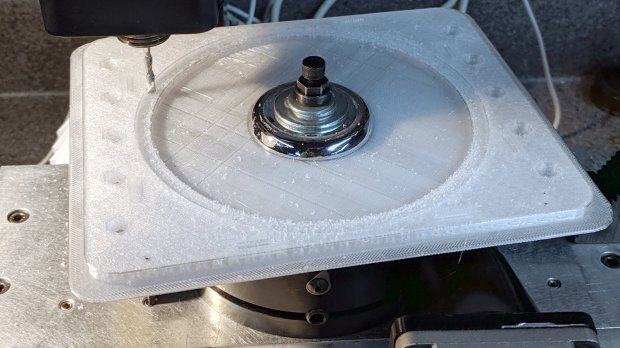

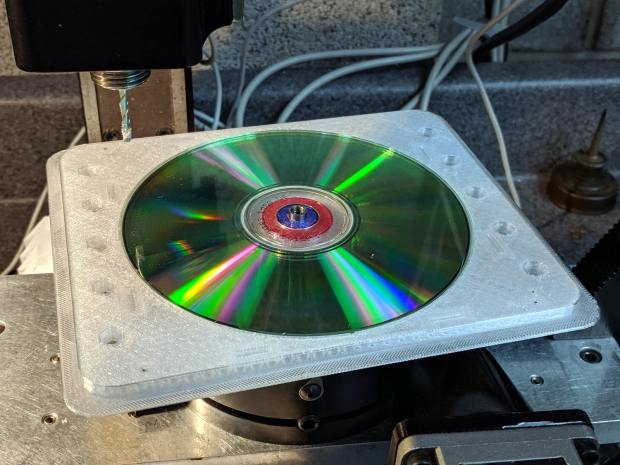

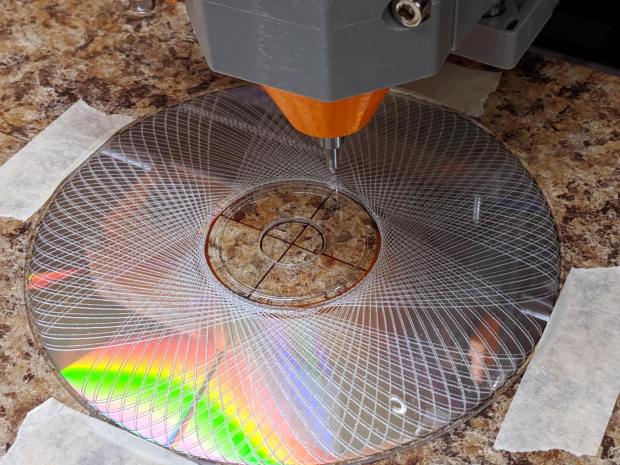

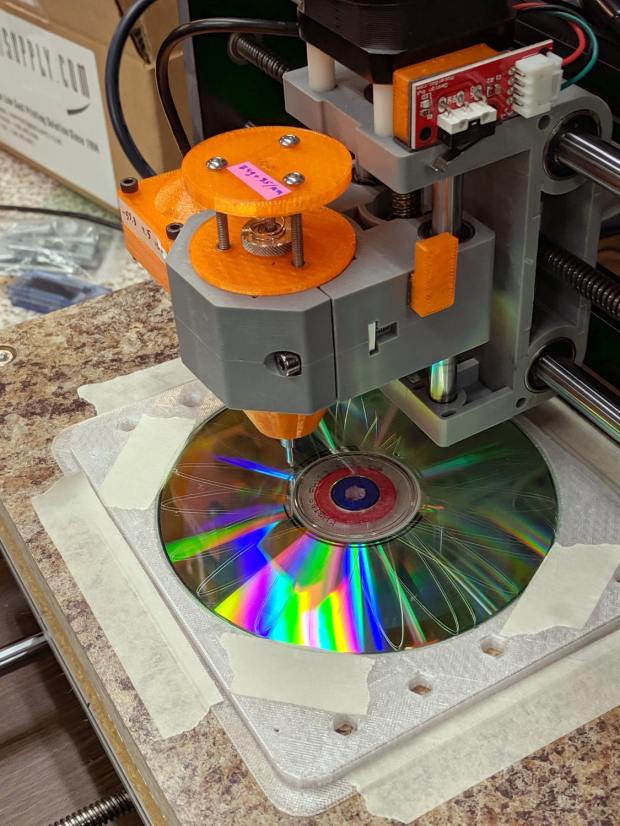

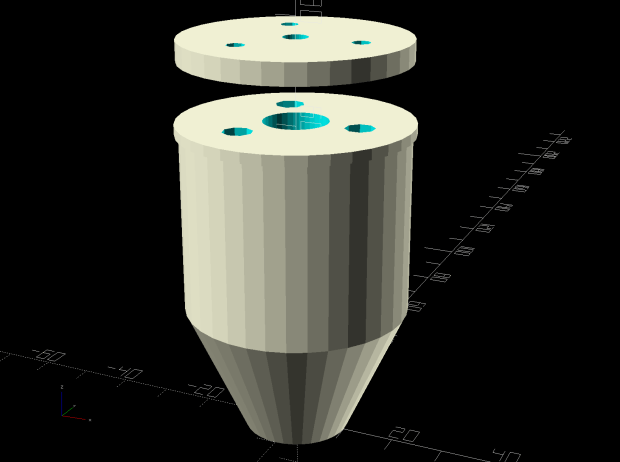

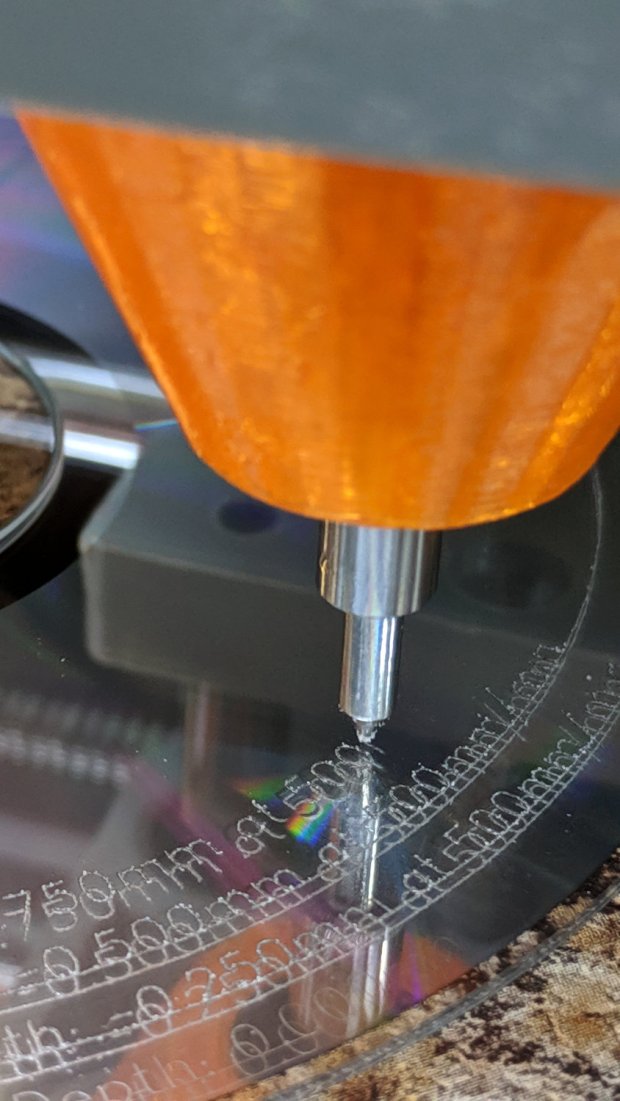

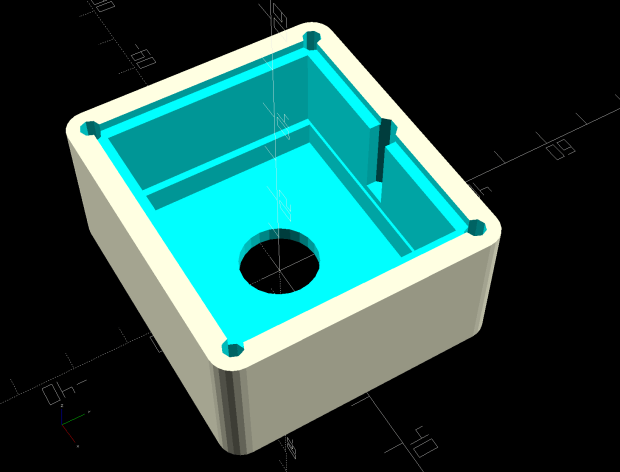

// Machining fixtures for CD and hard drive platters |

|

// Ed Nisley KE4ZNU February … September 2016 |

|

// 2019-08 split from tube base models |

|

|

|

PlatterName = "CD"; // [3.5inch,CD] |

|

|

|

CNCName = "3018"; // [3018,Sherline] |

|

|

|

TapeFlange = true; // Generate tape attachment |

|

|

|

PlateThick = 5.0; // [3.0,5.0,10.0,15.0] |

|

|

|

RecessDepth = 4.0; // [0.0,2.0,4.0] |

|

|

|

//- Extrusion parameters must match reality! |

|

|

|

/* [Hidden] */ |

|

|

|

ThreadThick = 0.25; |

|

ThreadWidth = 0.40; |

|

|

|

HoleWindage = 0.2; |

|

|

|

Protrusion = 0.1; // make holes end cleanly |

|

|

|

inch = 25.4; |

|

|

|

function IntegerMultiple(Size,Unit) = Unit * ceil(Size / Unit); |

|

|

|

module PolyCyl(Dia,Height,ForceSides=0) { // based on nophead's polyholes |

|

Sides = (ForceSides != 0) ? ForceSides : (ceil(Dia) + 2); |

|

FixDia = Dia / cos(180/Sides); |

|

cylinder(d=(FixDia + HoleWindage),h=Height,$fn=Sides); |

|

} |

|

|

|

|

|

ID = 0; |

|

OD = 1; |

|

LENGTH = 2; |

|

|

|

//———————- |

|

// Dimensions |

|

|

|

P_NAME = 0; // platter name |

|

P_ID = 1; // … inner diameter |

|

P_OD = 2; // … outer diameter |

|

P_THICK = 3; // … thickness |

|

|

|

PlatterData = [ |

|

["3.5inch", 25.0, 95.0, 1.75], |

|

["CD", 15.0, 120.0, 1.20], |

|

]; |

|

|

|

PlatterSides = 3*4*5; // polygon approximation |

|

|

|

B_NAME = 0; // machine name |

|

B_OC = 1; // … platform screw OC, use small integer for slot |

|

B_STUD = 2; // … screw OD clearance |

|

|

|

BaseData = [ |

|

["3018", [5.0, 45.0], 6.0], // slots along X axis |

|

["Sherline", [1.16*inch,1.16*inch], 5.0], // tooling plate |

|

|

|

]; |

|

|

|

PlateRound = 10.0; // corner radius |

|

|

|

FlangeSize = [5.0,5.0,3*ThreadThick]; // all-around tape flange |

|

|

|

//– calculate values based on input parameters |

|

|

|

PI = search([PlatterName],PlatterData,1,0)[P_NAME]; // get platter index |

|

echo(str("Platter: ",PlatterName)); |

|

Platter = [PlatterData[PI][P_ID], |

|

PlatterData[PI][P_OD], |

|

PlatterData[PI][P_THICK]]; |

|

|

|

BI = search([CNCName],BaseData,1,0)[B_NAME]; // get base index |

|

echo(str("Machine: ",CNCName)); |

|

|

|

AlignOC = IntegerMultiple(Platter[OD],10); |

|

echo(str("Alignment pip offset: ±",AlignOC/2)); |

|

AlignSlot = [3*ThreadWidth,10.0,3*ThreadThick]; |

|

|

|

StudClear = BaseData[BI][B_STUD]; // … clearance |

|

|

|

StudOC = [IntegerMultiple(AlignOC + 2*StudClear,BaseData[BI][B_OC].x), // … screw spacing |

|

BaseData[BI][B_OC].y]; |

|

echo(str("Stud spacing: ",StudOC)); |

|

NumStuds = [2,1 + 2*floor(Platter[OD] / StudOC.y)]; // holes only along ±X edges |

|

echo(str("Stud holes: ",NumStuds)); |

|

|

|

BasePlate = [(20 + StudOC.x*ceil(Platter[OD] / StudOC.x)), |

|

(10 + AlignOC), |

|

PlateThick]; |

|

echo(str("Plate: ",BasePlate)); |

|

|

|

Flange = [BasePlate.x + 2*FlangeSize.x,BasePlate.y + 2*FlangeSize.y,FlangeSize.z]; |

|

echo(str("Flange: ",Flange)); |

|

|

|

|

|

//———————- |

|

// Drilling fixture for disk platters |

|

|

|

module PlatterFixture() { |

|

|

|

difference() { |

|

union() { |

|

hull() // basic plate shape |

|

for (i=[-1,1], j=[-1,1]) |

|

translate([i*(BasePlate.x/2 – PlateRound),j*(BasePlate.y/2 – PlateRound),0]) |

|

cylinder(r=PlateRound,h=BasePlate.z,$fn=4*4); |

|

if (TapeFlange) |

|

hull() |

|

for (i=[-1,1], j=[-1,1]) |

|

translate([i*(Flange.x/2 – PlateRound), |

|

j*(Flange.y/2 – PlateRound), |

|

0]) |

|

cylinder(r=PlateRound,h=FlangeSize.z,$fn=4*4); |

|

} |

|

|

|

for (i=[-1,0,1], j=[-1,0,1]) // origin pips |

|

translate([i*AlignOC/2,j*AlignOC/2,BasePlate.z – 2*ThreadThick]) |

|

cylinder(d=4*ThreadWidth,h=1,$fn=6); |

|

|

|

for (i=[-1,1], j=[-1,1]) { // alignment slots |

|

translate([i*(AlignOC + AlignSlot.x)/2, |

|

j*Platter[OD]/4, |

|

(BasePlate.z – AlignSlot.z/2 + Protrusion/2)]) |

|

cube(AlignSlot + [0,0,Protrusion],center=true); |

|

translate([i*Platter[OD]/4, |

|

j*(AlignOC + AlignSlot.x)/2, |

|

(BasePlate.z – AlignSlot.z/2 + Protrusion/2)]) |

|

rotate(90) |

|

cube(AlignSlot + [0,0,Protrusion],center=true); |

|

} |

|

|

|

for (i=[-1,1], j=[-floor(NumStuds.y/2):floor(NumStuds.y/2)]) // mounting stud holes |

|

translate([i*StudOC.x/2,j*StudOC.y/2,-Protrusion]) |

|

rotate(180/6) |

|

PolyCyl(StudClear,BasePlate.z + 2*Protrusion,6); |

|

|

|

translate([0,0,-Protrusion]) // center clamp hole |

|

rotate(180/6) |

|

PolyCyl(StudClear,BasePlate.z + 2*Protrusion,6); |

|

|

|

translate([0,0,BasePlate.z – Platter[LENGTH]]) // disk locating recess |

|

rotate(180/PlatterSides) |

|

linear_extrude(height=(Platter[LENGTH] + Protrusion),convexity=2) |

|

difference() { |

|

circle(d=(Platter[OD] + 2*HoleWindage),$fn=PlatterSides); |

|

circle(d=Platter[ID] – HoleWindage,$fn=PlatterSides); |

|

} |

|

|

|

translate([0,0,BasePlate.z – RecessDepth]) // drilling recess |

|

rotate(180/PlatterSides) |

|

linear_extrude(height=(RecessDepth + Protrusion),convexity=2) |

|

difference() { |

|

circle(d=(Platter[OD] – 10),$fn=PlatterSides); |

|

circle(d=(Platter[ID] + 10),$fn=PlatterSides); |

|

} |

|

} |

|

|

|

} |

|

|

|

|

|

//———————- |

|

// Build it |

|

|

|

PlatterFixture(); |

|

|