The button definition table now includes a string that becomes the button’s command to the sewing machine motor controller:

#define MAXCMDLEN 2

enum bstatus_t {BT_DISABLED,BT_UP,BT_DOWN};

typedef void (*pBtnFn)(byte BID); // button action function called when hit

struct button_t {

byte ID; // button identifier, 0 unused

byte Group; // radio button group, 0 for none

byte Status; // button status

word ulX,ulY; // origin: upper left

word szX,szY; // button image size

pBtnFn pAction; // button function

char Cmd[MAXCMDLEN + 1]; // command string

char NameStem[9]; // button BMP file name - stem only

};

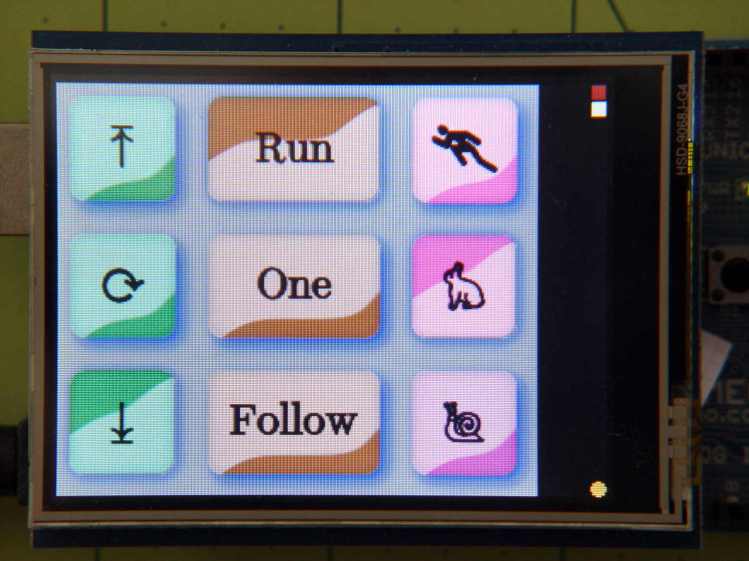

struct button_t Buttons[] = {

{ 1, 1, BT_UP, 0,0, 80,80, DefaultAction, "Nu", "NdUp"},

{ 2, 1, BT_UP, 0,80, 80,80, DefaultAction, "Na", "NdAny"},

{ 3, 1, BT_DOWN, 0,160, 80,80, DefaultAction, "Nd", "NdDn"},

{ 4, 2, BT_DOWN, 80,0, 120,80, DefaultAction, "Pr", "PdRun"},

{ 5, 2, BT_UP, 80,80, 120,80, DefaultAction, "P1", "PdOne"},

{ 6, 2, BT_UP, 80,160, 120,80, DefaultAction, "Pf", "PdFol"},

{ 7, 3, BT_DOWN, 200,0, 80,80, DefaultAction, "Sh", "SpMax"},

{ 8, 3, BT_UP, 200,80, 80,80, DefaultAction, "Sm", "SpMed"},

{ 9, 3, BT_UP, 200,160, 80,80, DefaultAction, "Sl", "SpLow"},

// {10, 0, BT_UP, 311,0, 8,8, CountColor, '\0', '\0', "Res"}

};

byte NumButtons = sizeof(Buttons) / sizeof(struct button_t);

The default button handler now sends the button’s command string whenever it finds the button down after all the processing:

#define TRACEACTION false

void DefaultAction(byte BID) {

byte i,BX;

byte Group;

if (!BID) { // not a valid ID

printf("** Button ID zero in DefaultAction\r\n");

return;

}

BX = FindButtonIndex(BID);

if (BX == NumButtons) { // no button for that ID

// printf("** No table entry for ID: %d\r\n",BID);

return;

}

#if TRACEACTION

printf("Default action: BID %d St %d -- ",BID,Buttons[BX].Status);

#endif

if (Buttons[BX].Status == BT_DISABLED) { // cannot do anything to disabled buttons

#if TRACEACTION

printf("disabled\r\n");

#endif

return;

}

Group = Buttons[BX].Group;

if (Group) { // member of group?

if (Buttons[BX].Status == BT_DOWN) { // if down, remain that way

#if TRACEACTION

printf("already down\r\n");

#endif

}

else { // is up

for (i=0; i<NumButtons; i++) { // so unpush other buttons in group

if ((Buttons[i].Group == Group) && (Buttons[i].Status == BT_DOWN) && (i != BX)) {

#if TRACEACTION

printf("release ID %d - ",Buttons[i].ID);

#endif

Buttons[i].Status = BT_UP;

DrawButton(Buttons[i].ID,Buttons[i].Status);

}

}

#if TRACEACTION

printf("push\r\n");

#endif

Buttons[BX].Status = BT_DOWN; // and push this button down

}

}

else { // not a group, so just toggle

#if TRACEACTION

printf("toggle\r\n");

#endif

Buttons[BX].Status = (Buttons[BX].Status == BT_DOWN) ? BT_UP : BT_DOWN;

}

DrawButton(BID,Buttons[BX].Status);

if (Buttons[BX].Status == BT_DOWN) { // is this button now (or still) pressed?

SendCmd(Buttons[BX].Cmd);

}

}

That means the controller will see identical commands each time the button gets pressed, which doesn’t have any downsides. You could build an increment / decrement speed function without much trouble, although there’s still no way to display any returned values on the LCD.

Working under the possibly unwarranted assumption that serial communications between the two Arduinos won’t encounter any errors, I just wrap the command string in a distinctive marker and send it off:

void SendCmd(char *pCmd) {

char Msg[MAXCMDLEN + 3];

strcpy(Msg,"[");

strcat(Msg,pCmd);

strcat(Msg,"]");

Serial.print("Cmd: "); // copy to console

Serial.println(Msg);

Serial1.println(Msg); // send command!

}

The Serial1 port runs at a nose-pickin’ 9600 baud, because the motor controller often gets wrapped up in what it’s doing. On the other paw, when the controller gets distracted, the operator will be feeding fabric past the needle at a pretty good clip and won’t have a finger to spare for the UI buttons, so it would probably work no matter what.

That mismatch, however, allows the motor controller to babble on at length, without overruning the UI’s console output. This routine collects lines from the controller:

char GetStatLine(void) {

static byte Index = 0;

char NewChar;

if (!Serial1.available()) { // return if no chars in queue

return 0;

}

do {

NewChar = Serial1.read();

switch (NewChar) {

case '\r': // end-of-line on CR

MCtlBuffer[Index] = 0;

Index = 0;

return strlen(MCtlBuffer); // return from mid-loop

break; // unnecessary

case '\n': // discard NL

break;

default:

MCtlBuffer[Index] = NewChar; // store all others

Index += (Index < STATMAXLEN) ? 1 : 0;

}

} while (Serial1.available());

return 0;

}

A call in the main loop dumps each line after the terminating CR:

char GetStatLine(void) {

static byte Index = 0;

char NewChar;

if (!Serial1.available()) { // return if no chars in queue

return 0;

}

do {

NewChar = Serial1.read();

switch (NewChar) {

case '\r': // end-of-line on CR

MCtlBuffer[Index] = 0;

Index = 0;

return strlen(MCtlBuffer); // return from mid-loop

break; // unnecessary

case '\n': // discard NL

break;

default:

MCtlBuffer[Index] = NewChar; // store all others

Index += (Index < STATMAXLEN) ? 1 : 0;

}

} while (Serial1.available());

return 0;

}

Which produces output like this:

Kenmore Model 158 User Interface Compiled: Jan 26 2015 at 15:33:52 Ed Nisley - KE4ZNU TS... OK SD... OK LCD... should be active Cmd: [Nd] Cmd: [Pr] Cmd: [Sh] MC |** Bad command string: [--] MC | 540, 65535, 194 MC | 610, 0, 194 MC | 783, 55, 236 MC | 1262, 84, 391 MC | 1452, 116, 394 MC | 1633, 123, 394 MC | 1494, 132, 405 MC | 1768, 126, 406 MC | 1488, 126, 406 MC | 1425, 137, 406 MC | 1517, 132, 406 MC | 1461, 126, 209 MC |Coast: 1099 MC |Parking Stop down: Done MC | stopped

The “bad command string” isn’t actually an error. The first outbound line consists of [--] and a carriage return, which isn’t a valid command, just to make sure that the motor controller’s incoming serial port buffer doesn’t contain any junk. Obviously, I should add that string to the command decoder…