|

// Vacuum Tube LED Lights |

|

// Ed Nisley KE4ZNU January 2016 |

|

|

|

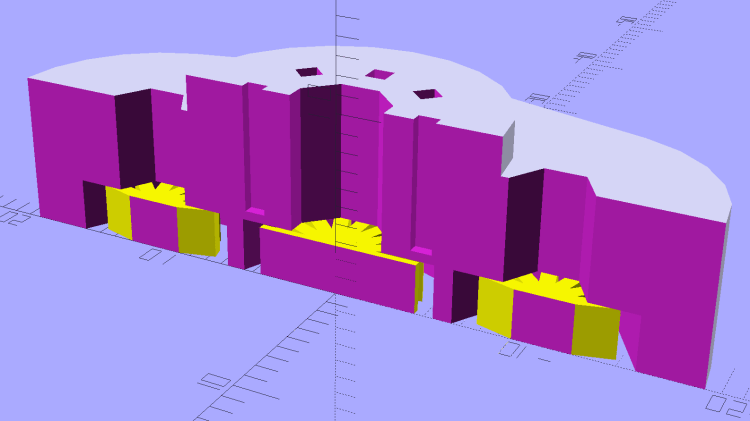

Layout = "FinCap"; // Cap LampBase USBPort Socket(s) (Build)FinCap |

|

|

|

Section = true; // cross-section the object |

|

|

|

Support = true; |

|

|

|

//- Extrusion parameters must match reality! |

|

|

|

ThreadThick = 0.25; |

|

ThreadWidth = 0.40; |

|

|

|

HoleWindage = 0.2; |

|

|

|

Protrusion = 0.1; // make holes end cleanly |

|

|

|

inch = 25.4; |

|

|

|

function IntegerMultiple(Size,Unit) = Unit * ceil(Size / Unit); |

|

|

|

//———————- |

|

// Dimensions |

|

// https://en.wikipedia.org/wiki/Tube_socket#Summary_of_Base_Details |

|

|

|

T_NAME = 0; // common name |

|

T_NUMPINS = 1; // total, with no allowance for keying |

|

T_PINBCD = 2; // tube pin circle diameter |

|

T_PINOD = 3; // … diameter |

|

T_PINLEN = 4; // … length (overestimate) |

|

T_HOLEOD = 5; // nominal panel hole from various sources |

|

T_PUNCHOD = 6; // panel hole optimized for inch-size Greenlee punches |

|

T_TUBEOD = 7; // envelope or base diameter |

|

T_PIPEOD = 8; // light pipe from LED to tube base |

|

T_SCREWOC = 9; // mounting screw holes |

|

|

|

// Name pins BCD dia length hole punch env pipe screw |

|

TubeData = [ |

|

["Mini7", 8, 9.53, 1.016, 7.0, 16.0, 11/16 * inch, 18.0, 5.0, 22.5], |

|

["Octal", 8, 17.45, 2.36, 10.0, 36.2, (8 + 1)/8 * inch, 32.0, 11.5, 39.0], |

|

["Noval", 10, 11.89, 1.1016, 7.0, 22.0, 7/8 * inch, 21.0, 5.0, 28.0], |

|

["Duodecar", 13, 19.10, 1.05, 9.0, 32.0, 1.25 * inch, 38.0, 12.5, 39.0], |

|

]; |

|

|

|

ID = 0; |

|

OD = 1; |

|

LENGTH = 2; |

|

|

|

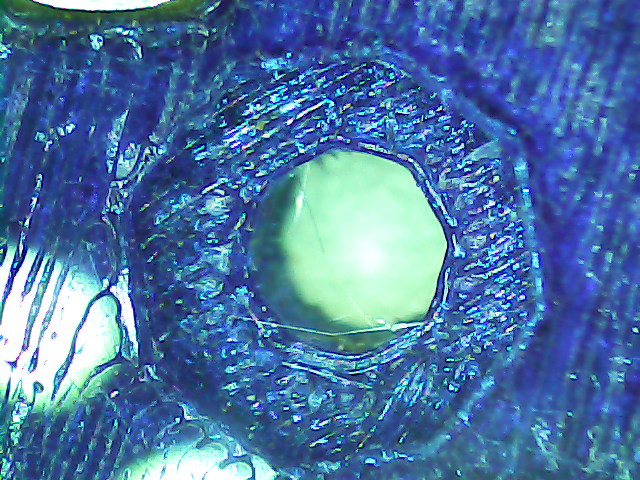

Pixel = [7.0,10.0,3.0]; // ID = contact patch, OD = PCB dia, LENGTH = overall thickness |

|

|

|

Nut = [3.5,8.0,3.0]; // socket mounting nut recess |

|

|

|

BaseShim = 2*ThreadThick; // between pin holes and pixel top |

|

SocketFlange = 2.0; // rim around socket below punchout |

|

PanelThick = 2.0; // socket extension through punchout |

|

|

|

//———————- |

|

// Useful routines |

|

|

|

module PolyCyl(Dia,Height,ForceSides=0) { // based on nophead's polyholes |

|

|

|

Sides = (ForceSides != 0) ? ForceSides : (ceil(Dia) + 2); |

|

|

|

FixDia = Dia / cos(180/Sides); |

|

|

|

cylinder(r=(FixDia + HoleWindage)/2,h=Height,$fn=Sides); |

|

} |

|

|

|

//———————- |

|

// Tube cap |

|

|

|

CapTube = [4.0,3/16 * inch,10.0]; // brass tube for flying lead to cap LED |

|

|

|

CapSize = [Pixel[ID],(Pixel[OD] + 3.0),(CapTube[OD] + 2*Pixel[LENGTH])]; |

|

|

|

CapSides = 6*4; |

|

|

|

module Cap() { |

|

|

|

difference() { |

|

union() { |

|

cylinder(d=CapSize[OD],h=(CapSize[LENGTH]),$fn=CapSides); // main cap body |

|

translate([0,0,CapSize[LENGTH]]) // rounded top |

|

scale([1.0,1.0,0.65]) |

|

sphere(d=CapSize[OD]/cos(180/CapSides),$fn=CapSides); // cos() fixes slight undersize vs cylinder |

|

cylinder(d1=(CapSize[OD] + 2*3*ThreadWidth),d2=CapSize[OD],h=1.5*Pixel[LENGTH],$fn=CapSides); // skirt |

|

} |

|

|

|

translate([0,0,-Protrusion]) // bore for wiring to LED |

|

PolyCyl(CapSize[ID],(CapSize[LENGTH] + 3*ThreadThick + Protrusion),CapSides); |

|

|

|

translate([0,0,-Protrusion]) // PCB recess with clearance for tube dome |

|

PolyCyl(Pixel[OD],(1.5*Pixel[LENGTH] + Protrusion),CapSides); |

|

|

|

translate([0,0,(1.5*Pixel[LENGTH] – Protrusion)]) // small step + cone to retain PCB |

|

cylinder(d1=(Pixel[OD]/cos(180/CapSides)),d2=Pixel[ID],h=(Pixel[LENGTH] + Protrusion),$fn=CapSides); |

|

|

|

translate([0,0,(CapSize[LENGTH] – CapTube[OD]/(2*cos(180/8)))]) // hole for brass tube holding wire loom |

|

rotate([90,0,0]) rotate(180/8) |

|

PolyCyl(CapTube[OD],CapSize[OD],8); |

|

} |

|

|

|

} |

|

|

|

//———————- |

|

// Heatsink tube cap |

|

|

|

CableOD = 3.5; // cable + braid diameter |

|

BulbOD = 3.75 * inch; // bulb OD; use 10 inches for flat |

|

|

|

FinCutterOD = 1/8 * inch; |

|

echo(str("Fin Cutter: ",FinCutterOD)); |

|

FinSides = 2*4; |

|

|

|

FinCapSize = [(Pixel[OD] + 2*FinCutterOD),30.0,(10.0 + 2*Pixel[LENGTH])]; |

|

|

|

BulbRadius = BulbOD / 2; |

|

BulbDepth = BulbRadius – sqrt(pow(BulbRadius,2) – pow(FinCapSize[OD],2)/4); |

|

echo(str("Bulb OD: ",BulbOD," recess: ",BulbDepth)); |

|

|

|

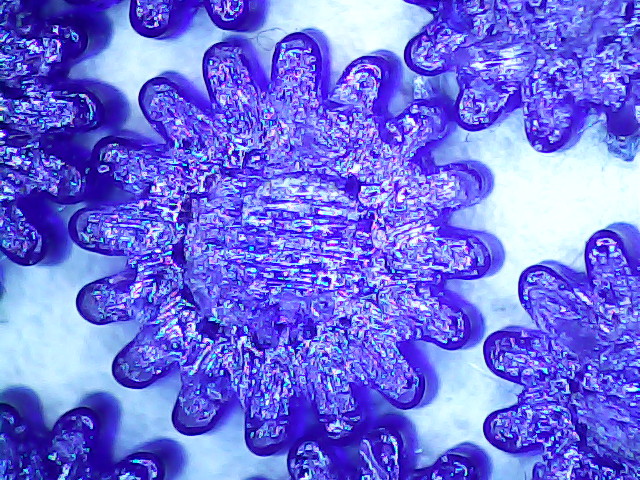

module FinCap() { |

|

|

|

NumFins = floor(PI*FinCapSize[ID] / (2*FinCutterOD)); |

|

FinAngle = 360 / NumFins; |

|

echo(str("NumFins: ",NumFins," angle: ",FinAngle," deg")); |

|

|

|

difference() { |

|

union() { |

|

cylinder(d=FinCapSize[ID],h=FinCapSize[LENGTH],$fn=2*NumFins); // main body |

|

|

|

for (i = [0:NumFins – 1]) // fins |

|

rotate(i * FinAngle) |

|

hull() { |

|

translate([FinCapSize[ID]/2,0,0]) |

|

rotate(180/FinSides) |

|

cylinder(d=FinCutterOD,h=FinCapSize[LENGTH],$fn=FinSides); |

|

translate([(FinCapSize[OD] – FinCutterOD)/2,0,0]) |

|

rotate(180/FinSides) |

|

cylinder(d=FinCutterOD,h=FinCapSize[LENGTH],$fn=FinSides); |

|

} |

|

|

|

rotate(FinAngle/2) // cable entry boss |

|

translate([FinCapSize[ID]/2,0,FinCapSize[LENGTH]/2]) |

|

cube([FinCapSize[OD]/4,FinCapSize[OD]/4,FinCapSize[LENGTH]],center=true); |

|

} |

|

|

|

for (i = [1:NumFins – 1]) // fin inner gullets, omit cable entry side |

|

rotate(i * FinAngle + FinAngle/2) // joint isn't quite perfect, but OK |

|

translate([FinCapSize[ID]/2,0,-Protrusion]) |

|

rotate(0*180/FinSides) |

|

cylinder(d=FinCutterOD/cos(180/FinSides),h=(FinCapSize[LENGTH] + 2*Protrusion),$fn=FinSides); |

|

|

|

translate([0,0,-Protrusion]) // PCB recess |

|

PolyCyl(Pixel[OD],(1.5*Pixel[LENGTH] + Protrusion),FinSides); |

|

|

|

PolyCyl(Pixel[ID],(FinCapSize[LENGTH] – 3*ThreadThick),FinSides); // bore for LED wiring |

|

|

|

translate([0,0,(FinCapSize[LENGTH] – 3*ThreadThick – 2*CableOD/(2*cos(180/8)))]) // cable inlet |

|

rotate(FinAngle/2) rotate([0,90,0]) rotate(180/8) |

|

PolyCyl(CableOD,FinCapSize[OD],8); |

|

|

|

if (BulbOD <= 10.0 * inch) // curve for top of bulb |

|

translate([0,0,-(BulbRadius – BulbDepth + 2*ThreadThick)]) // … slightly flatten tips |

|

sphere(d=BulbOD,$fn=16*FinSides); |

|

} |

|

|

|

} |

|

|

|

|

|

//———————- |

|

// Aperture for USB-to-serial adapter snout |

|

// These are all magic numbers, of course |

|

|

|

module USBPort() { |

|

|

|

translate([0,28.0]) |

|

rotate([90,0,0]) |

|

linear_extrude(height=28.0) |

|

polygon(points=[ |

|

[0,0], |

|

[8.0,0], |

|

[8.0,4.0], |

|

// [4.0,4.0], |

|

[4.0,6.5], |

|

[-4.0,6.5], |

|

// [-4.0,4.0], |

|

[-8.0,4.0], |

|

[-8.0,0], |

|

]); |

|

} |

|

|

|

|

|

//———————- |

|

// Box for Leviton ceramic lamp base |

|

|

|

module LampBase() { |

|

|

|

Bottom = 3.0; |

|

Base = [4.0*inch,4.5*inch,20.0 + Bottom]; |

|

Sides = 12*4; |

|

|

|

Retainer = [3.5,11.0,1.0]; // flat fiber washer holding lamp base screws in place |

|

|

|

StudSides = 8; |

|

StudOC = 3.5 * inch; |

|

Stud = [0.107 * inch, // 6-32 mounting screws |

|

min(15.0,1.5*(Base[ID] – StudOC)/cos(180/StudSides)), // OD = big enough to merge with walls |

|

(Base[LENGTH] – Retainer[LENGTH])]; // leave room for retainer |

|

|

|

|

|

union() { |

|

difference() { |

|

rotate(180/Sides) |

|

cylinder(d=Base[OD],h=Base[LENGTH],$fn=Sides); |

|

rotate(180/Sides) |

|

translate([0,0,Bottom]) |

|

cylinder(d=Base[ID],h=Base[LENGTH],$fn=Sides); |

|

translate([0,-Base[OD]/2,Bottom + 1.2]) // mount on double-sided foam tape |

|

rotate(0) |

|

USBPort(); |

|

} |

|

for (i = [-1,1]) |

|

translate([i*StudOC/2,0,0]) |

|

rotate(180/StudSides) |

|

difference() { |

|

# cylinder(d=Stud[OD],h=Stud[LENGTH],$fn=StudSides); |

|

translate([0,0,Bottom]) |

|

PolyCyl(Stud[ID],(Stud[LENGTH] – (Bottom – Protrusion)),6); |

|

} |

|

} |

|

} |

|

|

|

//———————- |

|

// Tube Socket |

|

|

|

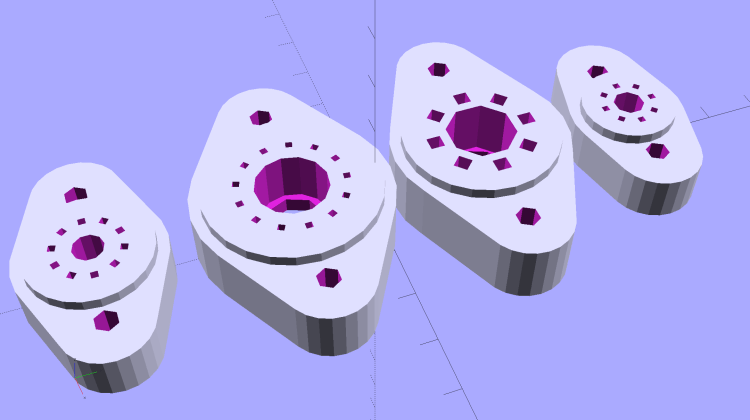

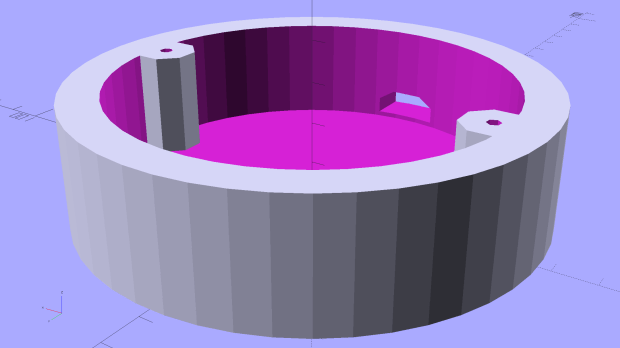

module Socket(Name = "Mini7") { |

|

|

|

NumSides = 6*4; |

|

|

|

Tube = search([Name],TubeData,1,0)[0]; |

|

echo(str("Building ",TubeData[Tube][0]," socket")); |

|

echo(str(" Punch: ",TubeData[ID][T_PUNCHOD]," mm = ",TubeData[ID][T_PUNCHOD]/inch," inch")); |

|

echo(str(" Screws: ",TubeData[ID][T_SCREWOC]," mm =",TubeData[ID][T_SCREWOC]/inch," inch OC")); |

|

|

|

OAH = Pixel[LENGTH] + BaseShim + TubeData[Tube][T_PINLEN]; |

|

BaseHeight = OAH – PanelThick; |

|

|

|

difference() { |

|

union() { |

|

linear_extrude(height=BaseHeight) |

|

hull() { |

|

circle(d=(TubeData[Tube][T_PUNCHOD] + 2*SocketFlange),$fn=NumSides); |

|

for (i=[-1,1]) |

|

translate([i*TubeData[Tube][T_SCREWOC]/2,0]) |

|

circle(d=2*Nut[OD],$fn=NumSides); |

|

} |

|

cylinder(d=TubeData[Tube][T_PUNCHOD],h=OAH,$fn=NumSides); |

|

} |

|

|

|

for (i=[0:(TubeData[Tube][T_NUMPINS] – 1)]) // tube pins |

|

rotate(i*360/TubeData[Tube][T_NUMPINS]) |

|

translate([TubeData[Tube][T_PINBCD]/2,0,(OAH – TubeData[Tube][T_PINLEN])]) |

|

rotate(180/4) |

|

PolyCyl(TubeData[Tube][T_PINOD],(TubeData[Tube][T_PINLEN] + Protrusion),4); |

|

|

|

for (i=[-1,1]) // mounting screw holes & nut traps |

|

translate([i*TubeData[Tube][T_SCREWOC]/2,0,-Protrusion]) { |

|

PolyCyl(Nut[OD],(Nut[LENGTH] + Protrusion),6); |

|

PolyCyl(Nut[ID],(OAH + 2*Protrusion),6); |

|

} |

|

|

|

translate([0,0,-Protrusion]) { // LED recess |

|

PolyCyl(Pixel[OD],(Pixel[LENGTH] + Protrusion),8); |

|

} |

|

|

|

translate([0,0,(Pixel[LENGTH] – Protrusion)]) { // light pipe |

|

rotate(180/TubeData[Tube][T_NUMPINS]) |

|

PolyCyl(TubeData[Tube][T_PIPEOD],(OAH + 2*Protrusion),TubeData[Tube][T_NUMPINS]); |

|

} |

|

} |

|

|

|

// Totally ad-hoc support structures … |

|

|

|

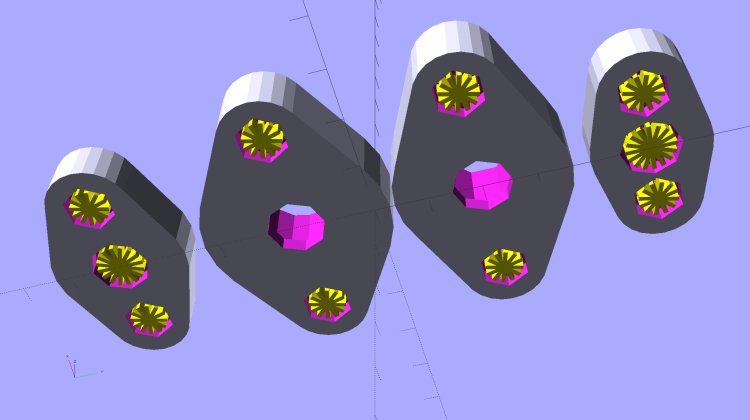

if (Support) { |

|

color("Yellow") { |

|

for (i=[-1,1]) // nut traps |

|

translate([i*TubeData[Tube][T_SCREWOC]/2,0,(Nut[LENGTH] – ThreadThick)/2]) |

|

for (a=[0:5]) |

|

rotate(a*30 + 15) |

|

cube([2*ThreadWidth,0.9*Nut[OD],(Nut[LENGTH] – ThreadThick)],center=true); |

|

|

|

if (Pixel[OD] > TubeData[Tube][T_PIPEOD]) // support pipe only if needed |

|

translate([0,0,(Pixel[LENGTH] – ThreadThick)/2]) |

|

for (a=[0:7]) |

|

rotate(a*22.5) |

|

cube([2*ThreadWidth,0.9*Pixel[OD],(Pixel[LENGTH] – ThreadThick)],center=true); |

|

|

|

} |

|

} |

|

|

|

} |

|

|

|

//———————- |

|

// Build it |

|

|

|

if (Layout == "Cap") { |

|

if (Section) |

|

difference() { |

|

Cap(); |

|

translate([-CapSize[OD],0,CapSize[LENGTH]]) |

|

cube([2*CapSize[OD],2*CapSize[OD],3*CapSize[LENGTH]],center=true); |

|

} |

|

else |

|

Cap(); |

|

} |

|

|

|

if (Layout == "FinCap") { |

|

if (Section) render(convexity=5) |

|

difference() { |

|

FinCap(); |

|

// translate([0,-FinCapSize[OD],FinCapSize[LENGTH]]) |

|

// cube([2*FinCapSize[OD],2*FinCapSize[OD],3*FinCapSize[LENGTH]],center=true); |

|

translate([-FinCapSize[OD],0,FinCapSize[LENGTH]]) |

|

cube([2*FinCapSize[OD],2*FinCapSize[OD],3*FinCapSize[LENGTH]],center=true); |

|

} |

|

else |

|

FinCap(); |

|

} |

|

|

|

if (Layout == "BuildFinCap") |

|

translate([0,0,FinCapSize[LENGTH]]) |

|

rotate([180,0,0]) |

|

FinCap(); |

|

|

|

if (Layout == "LampBase") |

|

LampBase(); |

|

|

|

if (Layout == "USBPort") |

|

USBPort(); |

|

|

|

if (Layout == "Socket") |

|

if (Section) { |

|

difference() { |

|

Socket(); |

|

translate([-100/2,0,-Protrusion]) |

|

cube([100,50,50],center=false); |

|

} |

|

} |

|

else |

|

Socket(); |

|

|

|

if (Layout == "Sockets") { |

|

translate([0,50,0]) |

|

Socket("Mini7"); |

|

translate([0,20,0]) |

|

Socket("Octal"); |

|

translate([0,-15,0]) |

|

Socket("Duodecar"); |

|

translate([0,-50,0]) |

|

Socket("Noval"); |

|

} |