Because I wanted to discuss triac triggering for inductive loads, the triggering circuitry & firmware turned out to be absurdly complex. A quartet of transistors provides source and sink current, as well as source and sink clamps, with 1/8 cycle timing resolution. The transistors and their power supply must be optically isolated from the microcontroller, of course.

None of this triggering circuitry is quite what you want, but it’ll get you started in the right direction…

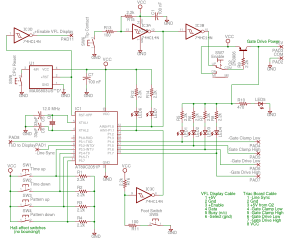

This schematic shows the driver circuitry, triac, transformer, and suchlike.

The weird +4 V supply comes directly from the small multi-tap transformer harvested from the ‘waver; your supply will certainly be different.

The 100 mΩ resistor in the primary is there strictly for current monitoring while debugging the thing. If you’re not doing that, leave it out.

The optocoupler in the lower right sends the zero-crossing time back to the microcontroller; it is vitally important that you get the phase correct on this one, as the firmware is doing triggering in all four quadrants and the triac doesn’t take kindly to pulses 180 degrees out of phase.

The microcontroller side looks pretty much like any 8051-based circuit.

I used a surplus VFL display with a serial input that required the 12.000 MHz crystal. That had the useful benefit of giving exact 1 µs instruction timing, but otherwise I’d have gone with a 11.0592 MHz crystal to get normal serial output bit timings.

The pushbuttons (lower left) are weird Hall-effect keyboard switches that are either open or pulled to the power supply; they do not have a low-active state. As a result, the resistors pull the inputs down in the inactive state. These switches don’t bounce, which simplified the firmware a bit. If you use mechanical switches, you must add a debouncing routine.

The Enable switch (upper right) provides positive control over the gate drive signals: when it’s open, the triac cannot fire.

The Contact switch (upper middle) seemed like a good idea: it’s supposed to close only when the electrodes are making firm contact. I never got around to building such a switch and it turns out to be unnecessary, so it’s bypassed by a toggle switch on the circuit board.

The Foot switch (lower middle) is absolutely vital: you get everything set up with electrodes properly arranged, then step on the switch. The microcontroller handles the timing, the heat goes off, and then you lift your foot at your leisure… when the joint is cool.

Here’s what all that looks like, all screwed to a piece of plywood in genuine breadboard mode:

Straight up: this is a lethally stupid way to build the thing. Put it inside a container of some sort, so you can’t drop anything conductive across the exposed primary components. OK?

Now, the reason I say none of this is what you want is because all resistance soldering requires is just turning the triac on for a while, then turning it off. I think duty-cycle control would be helpful, but sub-cycle timing is definitely not required.

So, by and large, were I to rebuild this, I’d jettison the entire triac triggering board and replace it with a simple optoisolated triac trigger IC (perhaps a MOC3022, of which I have a bag, or a TLP3042), then modify the firmware to flick a single output bit to turn on the heat.

You can download the schematics, simulation models, and source code from the Circuit Cellar FTP site: Issues 213 and 215.

Tomorrow: the firmware.