|

// Tektronix Circuit Computer Reproduction |

|

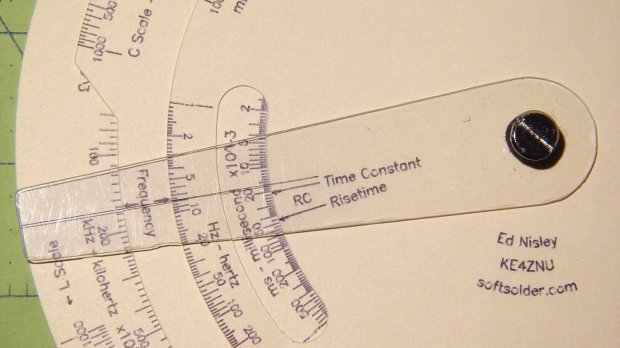

// Ed Nisley KE4ZNU – 2019-11 |

|

|

|

//—– |

|

// Library routines |

|

|

|

include("tracepath.inc.gcmc"); |

|

include("engrave.inc.gcmc"); |

|

|

|

TekOD = to_mm(7.75in); // orginal Tek Circuit Computer diameter |

|

|

|

FALSE = 0; |

|

TRUE = 1; |

|

|

|

//—– |

|

// Command line parameters |

|

|

|

// -D various useful tidbits |

|

// add unit to speeds and depths: 2000mm / -3.00mm / etc |

|

|

|

if (!isdefined("BaseOD")) { |

|

BaseOD = TekOD; |

|

} |

|

comment("Base OD: ",BaseOD); |

|

|

|

SizeRatio = BaseOD / TekOD; // overall scaling for different base diameters |

|

comment(" scale factor: ",SizeRatio); |

|

|

|

if (!isdefined("SelectPart")) { |

|

SelectPart = "Bottom"; |

|

} |

|

comment("Part: ",SelectPart); |

|

|

|

if (!isdefined("Operation")) { |

|

Operation = "Engrave"; |

|

} |

|

comment("Operation: ",Operation); |

|

|

|

if (!isdefined("ScaleSpeed")) { |

|

ScaleSpeed = 2400mm; |

|

} |

|

|

|

if (!isdefined("TextSpeed")) { |

|

TextSpeed = 2400mm; |

|

} |

|

|

|

// Engraving & drag knife force is proportional to depth, but you must know the coefficent! |

|

|

|

if (!isdefined("EngraveZ")) { |

|

EngraveZ = -1.0mm; |

|

} |

|

|

|

if (!isdefined("KnifeZ")) { |

|

KnifeZ = -2.0mm; |

|

} |

|

|

|

if (!isdefined("KnifeSpeed")) { |

|

KnifeSpeed = 1000mm; |

|

} |

|

|

|

//—– |

|

// Define useful constants |

|

|

|

SafeZ = 10.00mm; // above all obstructions |

|

TravelZ = 1.00mm; // within engraving area |

|

|

|

//—– |

|

// Overall values |

|

|

|

ScaleHeight = to_inch(3.0/8.0) * SizeRatio; // scale-to-scale distance |

|

WindowHeight = ScaleHeight; // cutout window opening |

|

|

|

DeckBottomOD = BaseOD; // deck sizes depend on scale height |

|

DeckMiddleOD = DeckBottomOD – 2*ScaleHeight; |

|

DeckTopOD = DeckMiddleOD – 2*(ScaleHeight + WindowHeight); |

|

|

|

ScaleArc = 18deg; // angular length of one decade: +CCW |

|

ScaleExdent = 0.20; // log spacing at end of scales to identifiers |

|

|

|

Scale2Pi = log10(2*pi()) * ScaleArc; // angular offset for scales using 2*pi |

|

ScaleRT = log10(2.197225) * ScaleArc; // angular offset for risetime |

|

|

|

TauAngle = 150deg; // arbitrary offset to 1.0 on tau scales |

|

TitleAngle = -50deg; // … to Tek title, then +180deg to logo |

|

|

|

INWARD = -1; // text and tick alignment (used as integers) |

|

OUTWARD = 1; |

|

|

|

TEXT_LEFT = -1; // text justification |

|

TEXT_CENTERED = 0; |

|

TEXT_RIGHT = 1; |

|

|

|

TextFont = FONT_HSANS_1_RS; |

|

|

|

TitleTextSize = 3.1 * SizeRatio * [1.0mm,1.0mm]; |

|

LegendTextSize = 1.8 * SizeRatio * [1.0mm,1.0mm]; |

|

ScaleTextSize = 1.4 * SizeRatio * [1.0mm,1.0mm]; |

|

|

|

//—- |

|

// Define tick layout for scales |

|

// Numeric values = scale position, tick length |

|

// These are not algorithmic! |

|

|

|

TickMajor = 3.2mm * SizeRatio; // length of tick marks |

|

TickMid = 1.9mm * SizeRatio; |

|

TickMinor = 1.2mm * SizeRatio; |

|

|

|

TickScaleNarrow = { |

|

[1.0,TickMajor], |

|

[1.1,TickMinor],[1.2,TickMinor],[1.3,TickMinor],[1.4,TickMinor], |

|

[1.5,TickMid], |

|

[1.6,TickMinor],[1.7,TickMinor],[1.8,TickMinor],[1.9,TickMinor], |

|

[2.0,TickMajor], |

|

[2.2,TickMinor],[2.4,TickMinor],[2.6,TickMinor],[2.8,TickMinor], |

|

[3.0,TickMajor], |

|

[3.2,TickMinor],[3.4,TickMinor],[3.6,TickMinor],[3.8,TickMinor], |

|

[4.0,TickMajor], |

|

[4.5,TickMinor], |

|

[5.0,TickMajor], |

|

[5.5,TickMinor], |

|

[6.0,TickMajor], |

|

[6.5,TickMinor], |

|

[7.0,TickMajor], |

|

[7.5,TickMinor], |

|

[8.0,TickMajor], |

|

[8.5,TickMinor], |

|

[9.0,TickMajor], |

|

[9.5,TickMinor] |

|

}; |

|

|

|

TickScaleWide = { |

|

[1.0,TickMajor], |

|

[1.1,TickMinor],[1.2,TickMinor],[1.3,TickMinor],[1.4,TickMinor], |

|

[1.5,TickMid], |

|

[1.6,TickMinor],[1.7,TickMinor],[1.8,TickMinor],[1.9,TickMinor], |

|

[2.0,TickMajor], |

|

[2.1,TickMinor],[2.2,TickMinor],[2.3,TickMinor],[2.4,TickMinor], |

|

[2.5,TickMid], |

|

[2.6,TickMinor],[2.7,TickMinor],[2.8,TickMinor],[2.9,TickMinor], |

|

[3.0,TickMajor], |

|

[3.2,TickMinor],[3.4,TickMinor],[3.6,TickMinor],[3.8,TickMinor], |

|

[4.0,TickMajor], |

|

[4.2,TickMinor],[4.4,TickMinor],[4.6,TickMinor],[4.8,TickMinor], |

|

[5.0,TickMajor], |

|

[5.5,TickMinor], |

|

[6.0,TickMajor], |

|

[6.5,TickMinor], |

|

[7.0,TickMajor], |

|

[7.5,TickMinor], |

|

[8.0,TickMajor], |

|

[8.5,TickMinor], |

|

[9.0,TickMajor], |

|

[9.5,TickMinor] |

|

}; |

|

|

|

TickLabels = [1,2,5]; // labels only these ticks, must be integers |

|

TickGap = 0.50 * ScaleTextSize.y; // gap between text and ticks |

|

|

|

PivotOD = 5.0mm; // center bolt OD |

|

|

|

Legend1 = "Ed Nisley – KE4ZNU"; |

|

Legend2 = "softsolder.com"; |

|

|

|

|

|

//—————————————————————————– |

|

// Text & Scale Engraving |

|

|

|

//—– |

|

// Write text on a radial line |

|

|

|

function RadialText(TextPath,CenterPt,Radius,Angle,Justify,Orient) { |

|

|

|

local pl = TextPath[-1].x; // path length |

|

|

|

local ji = (Justify == TEXT_LEFT) ? 0mm : // justification, assume OUTWARD |

|

(Justify == TEXT_CENTERED) ? -pl/2 : |

|

(Justify == TEXT_RIGHT) ? -pl : |

|

0mm; |

|

|

|

if (Orient == INWARD) { |

|

TextPath = rotate_xy(TextPath,180deg); |

|

ji = -ji; |

|

} |

|

|

|

TextPath += [Radius + ji,0mm]; |

|

|

|

return rotate_xy(TextPath,Angle) + CenterPt; |

|

|

|

} |

|

|

|

//—– |

|

// Draw a radial legend |

|

// Offset in units of char height: 0 = baseline on radius, +/- = above/below |

|

|

|

function RadialLegend(Text,Center,Radius,Angle,Justify,Orient,Offset) { |

|

|

|

local tp = scale(typeset(Text,TextFont),LegendTextSize) + [0mm,Offset * LegendTextSize.y]; |

|

local tpr = RadialText(tp,Center,Radius,Angle,Justify,Orient); |

|

|

|

feedrate(TextSpeed); |

|

engrave(tpr,TravelZ,EngraveZ); |

|

|

|

} |

|

|

|

//—– |

|

// Bend text around an arc |

|

|

|

function ArcText(TextPath,CenterPt,Radius,BaseAngle,Justify,Orient) { |

|

|

|

local pl = TextPath[-1].x; // path length |

|

local c = 2*pi()*Radius; |

|

local ta = to_deg(360 * pl / c); // subtended angle |

|

|

|

local ja = (Justify == TEXT_LEFT ? 0deg : // assume OUTWARD |

|

(Justify == TEXT_CENTERED) ? -ta / 2 : |

|

(Justify == TEXT_RIGHT) ? -ta : |

|

0deg); |

|

|

|

ja = BaseAngle + Orient*ja; |

|

|

|

local ArcPath = {}; |

|

|

|

local pt,r,a; |

|

foreach(TextPath; pt) { |

|

if (!isundef(pt.x) && !isundef(pt.y) && isundef(pt.z)) { // XY motion, no Z |

|

r = (Orient == OUTWARD) ? Radius – pt.y : Radius + pt.y; |

|

a = Orient * 360deg * (pt.x / c) + ja; |

|

ArcPath += {[r*cos(a) + CenterPt.x, r*sin(a) + CenterPt.y,-]}; |

|

} |

|

elif (isundef(pt.x) && isundef(pt.y) && !isundef(pt.z)) { // no XY, Z up/down |

|

ArcPath += {pt}; |

|

} |

|

else { |

|

error("ArcText – Point is not pure XY or pure Z: " + to_string(pt)); |

|

} |

|

} |

|

|

|

return ArcPath; |

|

|

|

} |

|

|

|

|

|

|

|

//—– |

|

// Draw scale legend |

|

|

|

function ArcLegend(Text,Radius,Angle,Orient) { |

|

|

|

local tp = scale(typeset(Text,TextFont),LegendTextSize); |

|

local tpa = ArcText(tp,[0mm,0mm],Radius,Angle,TEXT_CENTERED,Orient); |

|

|

|

feedrate(TextSpeed); |

|

engrave(tpa,TravelZ,EngraveZ); |

|

|

|

} |

|

|

|

|

|

//—– |

|

// Draw a decade of ticks & labels |

|

// ArcLength > 0 = CCW, < 0 = CW |

|

// UnitOnly forces just the unit tick, so as to allow creating the last tick of the scale |

|

|

|

function DrawTicks(Radius,TickMarks,TickOrient,UnitAngle,ArcLength,Decade,LabelOrient,UnitOnly) { |

|

|

|

feedrate(ScaleSpeed); |

|

|

|

local a,r0,r1,p0,p1; |

|

|

|

if (Decade == 1 || UnitOnly) { // draw unit marker |

|

a = UnitAngle; |

|

r0 = Radius + TickOrient * (TickMajor + 2*TickGap + ScaleTextSize.y); |

|

p0 = r0 * [cos(a),sin(a)]; |

|

r1 = Radius + TickOrient * (ScaleHeight – 2*TickGap); |

|

p1 = r1 * [cos(a),sin(a)]; |

|

|

|

goto(p0); |

|

move([-,-,EngraveZ]); |

|

move(p1); |

|

goto([-,-,TravelZ]); |

|

} |

|

|

|

local ticklist = UnitOnly ? {TickMarks[0]} : TickMarks; |

|

|

|

local tick; |

|

foreach(ticklist; tick) { |

|

a = UnitAngle + ArcLength * log10(tick[0]); |

|

p0 = Radius * [cos(a), sin(a)]; |

|

p1 = (Radius + TickOrient*tick[1]) * [cos(a), sin(a)]; |

|

|

|

goto(p0); |

|

move([-,-,EngraveZ]); |

|

move(p1); |

|

goto([-,-,TravelZ]); |

|

} |

|

|

|

feedrate(TextSpeed); // draw scale values |

|

|

|

local lrad = Radius + TickOrient * (TickMajor + TickGap); |

|

|

|

if (TickOrient == INWARD) { |

|

if (LabelOrient == INWARD) { |

|

lrad -= ScaleTextSize.y; // inward ticks + inward labels = offset inward |

|

} |

|

} |

|

else { |

|

if (LabelOrient == OUTWARD) { |

|

lrad += ScaleTextSize.y; // outward ticks + outward labels = offset outward |

|

} |

|

} |

|

|

|

ticklist = UnitOnly ? [TickLabels[0]] : TickLabels; |

|

|

|

local ltext,lpath,tpa; |

|

foreach(ticklist; tick) { |

|

ltext = to_string(Decade * to_int(tick)); |

|

lpath = scale(typeset(ltext,TextFont),ScaleTextSize); |

|

a = UnitAngle + ArcLength * log10(tick); |

|

tpa = ArcText(lpath,[0mm,0mm],lrad,a,TEXT_CENTERED,LabelOrient); |

|

engrave(tpa,TravelZ,EngraveZ); |

|

} |

|

|

|

} |

|

|

|

//—– |

|

// Mark key locations |

|

|

|

function MarkPivot() { |

|

|

|

comment("Mark center point"); |

|

feedrate(ScaleSpeed); |

|

|

|

if (TRUE) { |

|

goto([-,-,SafeZ]); |

|

goto([PivotOD/2,0,-]); |

|

move([-,-,EngraveZ]); |

|

circle_cw([0,0]); // outline pivot |

|

|

|

move([-PivotOD/2,0,-]); // draw X line |

|

goto([-,-,TravelZ]); |

|

goto([0,PivotOD/2,-]); |

|

move([-,-,EngraveZ]); |

|

move ([0,-PivotOD/2,-]); // draw Y line |

|

goto([-,-,TravelZ]); |

|

} |

|

|

|

} |

|

|

|

//—– |

|

// Draw attribution |

|

|

|

function DrawAttribution(AttribRad) { |

|

|

|

comment("Attribution at: ",AttribRad); |

|

|

|

feedrate(TextSpeed); |

|

|

|

local tp,tpa; |

|

if (Legend1) { |

|

tp = scale(typeset(Legend1,TextFont),TitleTextSize); |

|

tpa = ArcText(tp,[0mm,0mm],AttribRad,0deg,TEXT_CENTERED,OUTWARD); |

|

feedrate(TextSpeed); |

|

engrave(tpa,TravelZ,EngraveZ); |

|

} |

|

|

|

if (Legend2) { |

|

tp = scale(typeset(Legend2,TextFont),TitleTextSize); |

|

tpa = ArcText(tp,[0mm,0mm],AttribRad,180deg,TEXT_CENTERED,OUTWARD); |

|

feedrate(TextSpeed); |

|

engrave(tpa,TravelZ,EngraveZ); |

|

} |

|

|

|

if (FALSE) { // test code to verify ArcText |

|

comment("ArcText test"); |

|

ctr = [0mm,0mm]; |

|

|

|

tp = scale(typeset("Right Inward",TextFont),ScaleTextSize); |

|

tpa = ArcText(tp,ctr,30mm,45deg,TEXT_RIGHT,INWARD); |

|

engrave(tpa,TravelZ,EngraveZ); |

|

tp = scale(typeset("Right Outward",TextFont),ScaleTextSize); |

|

tpa = ArcText(tp,ctr,30mm,45deg,TEXT_RIGHT,OUTWARD); |

|

engrave(tpa,TravelZ,EngraveZ); |

|

|

|

tp = scale(typeset("Center Inward",TextFont),ScaleTextSize); |

|

tpa = ArcText(tp,ctr,20mm,45deg,TEXT_CENTERED,INWARD); |

|

engrave(tpa,TravelZ,EngraveZ); |

|

tp = scale(typeset("Center Outward",TextFont),ScaleTextSize); |

|

tpa = ArcText(tp,ctr,20mm,45deg,TEXT_CENTERED,OUTWARD); |

|

engrave(tpa,TravelZ,EngraveZ); |

|

|

|

tp = scale(typeset("Left Inward",TextFont),ScaleTextSize); |

|

tpa = ArcText(tp,ctr,10mm,45deg,TEXT_LEFT,INWARD); |

|

engrave(tpa,TravelZ,EngraveZ); |

|

tp = scale(typeset("Left Outward",TextFont),ScaleTextSize); |

|

tpa = ArcText(tp,ctr,10mm,45deg,TEXT_LEFT,OUTWARD); |

|

engrave(tpa,TravelZ,EngraveZ); |

|

|

|

goto([0mm,0mm,-]); |

|

move([40mm,40mm,-]); |

|

} |

|

|

|

if (FALSE) { // test code to verify RadialText |

|

comment("RadialText test"); |

|

ctr = [0mm,0mm]; |

|

r = 20mm; |

|

|

|

a = 0deg; |

|

tp = scale(typeset("Left Inward",TextFont),LegendTextSize); |

|

tpr = RadialText(tp,ctr,r,a,TEXT_LEFT,INWARD); |

|

feedrate(TextSpeed); |

|

engrave(tpr,TravelZ,EngraveZ); |

|

tp = scale(typeset("Left Outward",TextFont),LegendTextSize); |

|

tpr = RadialText(tp,ctr,r,a,TEXT_LEFT,OUTWARD); |

|

feedrate(TextSpeed); |

|

engrave(tpr,TravelZ,EngraveZ); |

|

|

|

a = 90deg; |

|

tp = scale(typeset("Right Inward",TextFont),LegendTextSize); |

|

tpr = RadialText(tp,ctr,r,a,TEXT_RIGHT,INWARD); |

|

feedrate(TextSpeed); |

|

engrave(tpr,TravelZ,EngraveZ); |

|

tp = scale(typeset("Right Outward",TextFont),LegendTextSize); |

|

tpr = RadialText(tp,ctr,r,a,TEXT_RIGHT,OUTWARD); |

|

feedrate(TextSpeed); |

|

engrave(tpr,TravelZ,EngraveZ); |

|

|

|

|

|

a = 180deg; |

|

tp = scale(typeset("Center Inward",TextFont),LegendTextSize); |

|

tpr = RadialText(tp,ctr,r,a,TEXT_CENTERED,INWARD); |

|

feedrate(TextSpeed); |

|

engrave(tpr,TravelZ,EngraveZ); |

|

tp = scale(typeset("Center Outward",TextFont),LegendTextSize); |

|

tpr = RadialText(tp,ctr,r,a,TEXT_CENTERED,OUTWARD); |

|

feedrate(TextSpeed); |

|

engrave(tpr,TravelZ,EngraveZ); |

|

|

|

a = 270deg; |

|

RadialLegend("Offset to radius",ctr,r,a,TEXT_CENTERED,INWARD,-0.5); |

|

goto(ctr); |

|

move([0,-2*r,EngraveZ]); |

|

|

|

goto([r,0mm,-]); |

|

circle_cw(ctr); |

|

|

|

} |

|

|

|

} |

|

|

|

//—————————————————————————– |

|

// Deck Engraving |

|

|

|

|

|

//———- |

|

// Engrave bottom deck |

|

|

|

function EngraveBottom() { |

|

|

|

// Mark center pivot |

|

|

|

MarkPivot(); |

|

|

|

comment("Inductance scale"); |

|

Radius = DeckRad – ScaleHeight; |

|

|

|

MinLog = -9; |

|

MaxLog = 6; |

|

Arc = -ScaleArc; |

|

|

|

dec = 1; |

|

offset = 0deg; |

|

for (logval = MinLog; logval < MaxLog; logval++) { |

|

a = offset + logval * Arc; |

|

DrawTicks(Radius,TickScaleNarrow,OUTWARD,a,Arc,dec,INWARD,FALSE); |

|

dec = (dec == 100) ? 1 : 10 * dec; |

|

} |

|

|

|

a = offset + MaxLog * Arc; |

|

DrawTicks(Radius,TickScaleNarrow,OUTWARD,a,Arc,1000,INWARD,TRUE); |

|

|

|

r = Radius + TickMajor + 2*TickGap + LegendTextSize.y; |

|

|

|

logval = MinLog + 1.5; |

|

a = offset + logval * Arc; |

|

ArcLegend("nH – nanohenry x10^-9",r,a,INWARD); |

|

|

|

logval += 3; |

|

a = offset + logval * Arc; |

|

ArcLegend("μH – microhenry x10^-6",r,a,INWARD); |

|

|

|

logval += 3; |

|

a = offset + logval * Arc; |

|

ArcLegend("mH – millihenry x10^-3",r,a,INWARD); |

|

|

|

logval += 3; |

|

a = offset + logval * Arc; |

|

ArcLegend("H – henry",r,a,INWARD); |

|

|

|

logval += 3; |

|

a = offset + logval * Arc; |

|

ArcLegend("kH – kilohenry x10^3",r,a,INWARD); |

|

|

|

r = Radius + TickMajor + TickGap; |

|

|

|

logval = MinLog – ScaleExdent; // scale identifiers |

|

a = offset + logval * Arc; |

|

tp = scale(typeset("L Scale →",TextFont),LegendTextSize); |

|

tpa = ArcText(tp,[0mm,0mm],r,a,TEXT_RIGHT,INWARD); |

|

engrave(tpa,TravelZ,EngraveZ); |

|

|

|

logval = MaxLog + ScaleExdent; |

|

a = offset + logval * Arc; |

|

tp = scale(typeset("← L Scale",TextFont),LegendTextSize); |

|

tpa = ArcText(tp,[0mm,0mm],r,a,TEXT_LEFT,INWARD); |

|

engrave(tpa,TravelZ,EngraveZ); |

|

|

|

comment("Inductive frequency scale"); |

|

|

|

Radius = DeckRad – 2*ScaleHeight; |

|

|

|

MinLog = 0; |

|

MaxLog = 9; |

|

Arc = 2*ScaleArc; // double-length scale for square roots |

|

|

|

dec = 1; |

|

offset = -(18 * ScaleArc – Scale2Pi); // using 18 degree arc length |

|

for (logval = MinLog; logval < MaxLog; logval++) { |

|

a = offset + logval * Arc; |

|

DrawTicks(Radius,TickScaleWide,OUTWARD,a,Arc,dec,OUTWARD,FALSE); |

|

dec = (dec == 100) ? 1 : 10 * dec; |

|

} |

|

|

|

a = offset + MaxLog * Arc; |

|

DrawTicks(Radius,TickScaleWide,OUTWARD,a,Arc,1000,OUTWARD,TRUE); |

|

|

|

feedrate(TextSpeed); // draw prefix legends |

|

|

|

r = Radius + TickMajor + 2*TickGap + 2*LegendTextSize.y; |

|

|

|

logval = MinLog + 0.5; |

|

|

|

for (i = 0; i < 3; i++) { |

|

a = offset + (i + logval) * Arc; |

|

ArcLegend("Hz – hertz",r,a,OUTWARD); |

|

} |

|

|

|

for (i = 3; i < 6; i++) { |

|

a = offset + (i + logval) * Arc; |

|

ArcLegend("kHz – kilohertz x10^3",r,a,OUTWARD); |

|

} |

|

|

|

for (i = 6; i < 9; i++) { |

|

a = offset + (i + logval) * Arc; |

|

ArcLegend("MHz – megahertz x10^6",r,a,OUTWARD); |

|

} |

|

|

|

r = Radius + TickMajor + TickGap + LegendTextSize.y; |

|

|

|

logval = MinLog – 0.5; // scale identifier |

|

a = offset + logval * Arc; |

|

ArcLegend("←——- FL Scale ——-→",r,a,OUTWARD); |

|

|

|

comment("Inductive TC / Risetime scale"); |

|

Radius = DeckRad – 3*ScaleHeight; |

|

|

|

MinLog = -12; |

|

MaxLog = 3; |

|

Arc = -ScaleArc; |

|

|

|

dec = 1; |

|

offset = -TauAngle; |

|

|

|

for (logval = MinLog; logval < MaxLog; logval++) { |

|

a = offset + logval * Arc; |

|

DrawTicks(Radius,TickScaleNarrow,OUTWARD,a,Arc,dec,INWARD,FALSE); |

|

dec = (dec == 100) ? 1 : 10 * dec; |

|

} |

|

|

|

a = offset + MaxLog * Arc; |

|

DrawTicks(Radius,TickScaleNarrow,OUTWARD,a,Arc,1000,INWARD,TRUE); |

|

|

|

feedrate(TextSpeed); // prefix legends |

|

|

|

r = Radius + TickMajor + 2*TickGap + LegendTextSize.y; |

|

|

|

logval = MinLog + 1.5; |

|

|

|

a = offset + logval * Arc; |

|

ArcLegend("ps – picosecond x10^-12",r,a,INWARD); |

|

|

|

logval += 3; |

|

a = offset + logval * Arc; |

|

ArcLegend("ns – nanosecond x10^-9",r,a,INWARD); |

|

|

|

logval += 3; |

|

a = offset + logval * Arc; |

|

ArcLegend("μs – microsecond x10^-6",r,a,INWARD); |

|

|

|

logval += 3; |

|

a = offset + logval * Arc; |

|

ArcLegend("ms – millisecond x10^-3",r,a,INWARD); |

|

|

|

logval += 3; |

|

a = offset + logval * Arc; |

|

ArcLegend("s – second",r,a,INWARD); |

|

|

|

r = Radius + TickMajor + TickGap; |

|

|

|

logval = MinLog – ScaleExdent; // scale identifiers |

|

a = offset + logval * Arc; |

|

tp = scale(typeset("τL Scale →",TextFont),LegendTextSize); |

|

tpa = ArcText(tp,[0mm,0mm],r,a,TEXT_RIGHT,INWARD); |

|

engrave(tpa,TravelZ,EngraveZ); |

|

|

|

logval = MaxLog + ScaleExdent; |

|

a = offset + logval * Arc; |

|

tp = scale(typeset("← τL Scale",TextFont),LegendTextSize); |

|

tpa = ArcText(tp,[0mm,0mm],r,a,TEXT_LEFT,INWARD); |

|

engrave(tpa,TravelZ,EngraveZ); |

|

|

|

//—– |

|

// Add construction notes |

|

|

|

comment("Attribution begins"); |

|

|

|

r = DeckTopOD/2 – 2*ScaleHeight – WindowHeight; |

|

DrawAttribution(r); |

|

|

|

if (FALSE) { |

|

t = "Disk OD: " + to_string(DeckBottomOD) + " " + |

|

to_string(DeckMiddleOD) + " " + |

|

to_string(DeckTopOD) + " mm"; |

|

tp = scale(typeset(t,TextFont),LegendTextSize); |

|

tpa = ArcText(tp,[0mm,0mm],r,90deg,TEXT_CENTERED,OUTWARD); |

|

engrave(tpa,TravelZ,EngraveZ); |

|

} |

|

|

|

goto([-,-,SafeZ]); // done, so get out of the way |

|

goto([0,0,-]); |

|

|

|

comment("Bottom deck ends"); |

|

|

|

} |

|

|

|

//———- |

|

// Engrave middle deck |

|

|

|

function EngraveMiddle() { |

|

|

|

// Mark center pivot |

|

|

|

MarkPivot(); |

|

|

|

comment("Capacitance scale"); |

|

Radius = DeckRad; |

|

|

|

MinLog = -15; |

|

MaxLog = 0; |

|

Arc = ScaleArc; |

|

|

|

dec = 1; |

|

offset = 0deg; |

|

for (logval = MinLog; logval < MaxLog; logval++) { |

|

a = offset + logval * Arc; |

|

DrawTicks(Radius,TickScaleNarrow,INWARD,a,Arc,dec,INWARD,FALSE); |

|

dec = (dec == 100) ? 1 : 10 * dec; |

|

} |

|

|

|

a = offset + MaxLog * Arc; |

|

DrawTicks(Radius,TickScaleNarrow,INWARD,a,Arc,1000,INWARD,TRUE); |

|

|

|

r = Radius – ScaleHeight + TickGap; |

|

|

|

logval = MinLog + 1.5; |

|

a = offset + logval * Arc; |

|

ArcLegend("fF – femtofarad x10^-15",r,a,INWARD); |

|

|

|

logval += 3; |

|

a = offset + logval * Arc; |

|

ArcLegend("pF – picofarad x10^-12",r,a,INWARD); |

|

|

|

logval += 2.5; // offset for L/R window; |

|

a = offset + logval * Arc; |

|

ArcLegend("nF – nanofarad x10^-9",r,a,INWARD); |

|

|

|

logval += 4; // … likewise |

|

a = offset + logval * Arc; |

|

ArcLegend("μF – microfarad x10^-6",r,a,INWARD); |

|

|

|

logval += 2.5; // … restore normal spacing |

|

a = offset + logval * Arc; |

|

ArcLegend("mF – millifarad x10^-3",r,a,INWARD); |

|

|

|

r = Radius – ScaleHeight – TickGap – LegendTextSize.y; // into blank space |

|

|

|

logval = MinLog; // scale identifiers |

|

a = offset + logval * Arc; |

|

tp = scale(typeset("←— C Scale",TextFont),LegendTextSize); |

|

tpa = ArcText(tp,[0mm,0mm],r,a,TEXT_RIGHT,INWARD); |

|

engrave(tpa,TravelZ,EngraveZ); |

|

|

|

logval = MinLog + 6; |

|

a = offset + logval * Arc; |

|

tp = scale(typeset("←— C Scale —→",TextFont),LegendTextSize); |

|

tpa = ArcText(tp,[0mm,0mm],r,a,TEXT_CENTERED,INWARD); |

|

engrave(tpa,TravelZ,EngraveZ); |

|

|

|

logval = MaxLog; |

|

a = offset + logval * Arc; |

|

tp = scale(typeset("C Scale —→",TextFont),LegendTextSize); |

|

tpa = ArcText(tp,[0mm,0mm],r,a,TEXT_LEFT,INWARD); |

|

engrave(tpa,TravelZ,EngraveZ); |

|

|

|

comment("Capacitive TC / risetime scale"); |

|

Radius = DeckRad – 4*ScaleHeight; |

|

|

|

MinLog = -12; |

|

MaxLog = 3; |

|

Arc = ScaleArc; |

|

|

|

dec = 1; |

|

offset = 3 * ScaleArc; |

|

for (logval = MinLog; logval < MaxLog; logval++) { |

|

a = offset + logval * Arc; |

|

DrawTicks(Radius,TickScaleNarrow,OUTWARD,a,Arc,dec,INWARD,FALSE); |

|

dec = (dec == 100) ? 1 : 10 * dec; |

|

} |

|

|

|

a = offset + MaxLog * Arc; |

|

DrawTicks(Radius,TickScaleNarrow,OUTWARD,a,Arc,1000,INWARD,TRUE); |

|

|

|

r = Radius + TickMajor + 2*TickGap + LegendTextSize.y; |

|

|

|

logval = MinLog + 1.5; |

|

a = offset + logval * Arc; |

|

ArcLegend("ps – picosecond x10^-12",r,a,INWARD); |

|

|

|

logval += 3; |

|

a = offset + logval * Arc; |

|

ArcLegend("ns – nanosecond x10^-9",r,a,INWARD); |

|

|

|

logval += 3; |

|

a = offset + logval * Arc; |

|

ArcLegend("μs – microsecond x10^-6",r,a,INWARD); |

|

|

|

logval += 3; |

|

a = offset + logval * Arc; |

|

ArcLegend("ms – millisecond x10^-3",r,a,INWARD); |

|

|

|

logval += 3; |

|

a = offset + logval * Arc; |

|

ArcLegend("s – second",r,a,INWARD); |

|

|

|

r = Radius + TickMajor + TickGap; |

|

|

|

logval = MinLog – ScaleExdent; // scale identifiers |

|

a = offset + logval * Arc; |

|

tp = scale(typeset("← τC Scale",TextFont),LegendTextSize); |

|

tpa = ArcText(tp,[0mm,0mm],r,a,TEXT_LEFT,INWARD); |

|

engrave(tpa,TravelZ,EngraveZ); |

|

|

|

logval = MaxLog + ScaleExdent; |

|

a = offset + logval * Arc; |

|

tp = scale(typeset("τC Scale →",TextFont),LegendTextSize); |

|

tpa = ArcText(tp,[0mm,0mm],r,a,TEXT_RIGHT,INWARD); |

|

engrave(tpa,TravelZ,EngraveZ); |

|

|

|

logval = MinLog – 2.5; |

|

a = offset + logval * Arc; |

|

tp = scale(typeset("←— τC Scale —→",TextFont),LegendTextSize); |

|

tpa = ArcText(tp,[0mm,0mm],r,a,TEXT_CENTERED,INWARD); |

|

engrave(tpa,TravelZ,EngraveZ); |

|

|

|

comment("Inductive frequency scale legend"); |

|

r = DeckRad – ScaleHeight – ScaleTextSize.y; |

|

a = 58deg; // arbitrary text placement |

|

ArcLegend("FL Scale",r,a,OUTWARD); |

|

|

|

comment("Index for resonance calculations"); |

|

Index = -(18*ScaleArc + Scale2Pi); // negative to read reciprocal of product |

|

|

|

r = DeckRad – 1.5*ScaleHeight + 0.5*LegendTextSize.y; |

|

ArcLegend("Frequency",r,Index,OUTWARD); |

|

|

|

r = DeckRad – ScaleHeight – LegendTextSize.y; |

|

ArcLegend("⇑",(r – TickGap),Index,INWARD); |

|

|

|

r = DeckRad – 2*ScaleHeight + LegendTextSize.y; |

|

ArcLegend("⇑",(r + TickGap),Index,OUTWARD); |

|

|

|

r0 = DeckRad – ScaleHeight; |

|

r1 = r0 – TickMajor; |

|

|

|

goto(r0 * [cos(Index),sin(Index)]); |

|

move([-,-,EngraveZ]); |

|

move(r1 * [cos(Index),sin(Index)]); |

|

goto([-,-,TravelZ]); |

|

|

|

r0 = DeckRad – 2*ScaleHeight; |

|

r1 = r0 + TickMajor; |

|

|

|

goto(r0 * [cos(Index),sin(Index)]); |

|

move([-,-,EngraveZ]); |

|

move(r1 * [cos(Index),sin(Index)]); |

|

goto([-,-,TravelZ]); |

|

|

|

|

|

//—– |

|

// Draw the attribution |

|

|

|

comment("Attribution begins"); |

|

|

|

r = DeckTopOD/2 – 2*ScaleHeight – WindowHeight; |

|

DrawAttribution(r); |

|

|

|

goto([-,-,SafeZ]); // done, so get out of the way |

|

goto([0,0,-]); |

|

|

|

comment("Middle deck ends"); |

|

|

|

} |

|

|

|

//———- |

|

// Engrave top deck |

|

|

|

function EngraveTop() { |

|

|

|

// Mark center pivot |

|

|

|

MarkPivot(); |

|

|

|

comment("Resistance scale"); |

|

Radius = DeckRad; |

|

|

|

MinLog = -1; |

|

MaxLog = 8; |

|

Arc = -ScaleArc; |

|

|

|

dec = 100; |

|

offset = 0deg; |

|

for (logval = MinLog; logval < MaxLog; logval++) { |

|

a = offset + logval * Arc; |

|

DrawTicks(Radius,TickScaleNarrow,INWARD,a,Arc,dec,INWARD,FALSE); |

|

dec = (dec == 100) ? 1 : 10 * dec; |

|

} |

|

|

|

a = offset + MaxLog * Arc; |

|

DrawTicks(Radius,TickScaleNarrow,INWARD,a,Arc,100,INWARD,TRUE); |

|

|

|

r = Radius – ScaleHeight + TickGap; |

|

|

|

logval = MinLog + 0.5; |

|

a = offset + logval * Arc; |

|

ArcLegend("mΩ – milliohm",r,a,INWARD); |

|

|

|

logval = MinLog + 2.5; |

|

a = offset + logval * Arc; |

|

ArcLegend("Ω – ohm",r,a,INWARD); |

|

|

|

logval += 3; |

|

a = offset + logval * Arc; |

|

ArcLegend("kΩ – kilohm x10^3",r,a,INWARD); |

|

|

|

logval = MaxLog – 1; |

|

a = offset + logval * Arc; |

|

ArcLegend("MΩ – megohm x10^6",r,a,INWARD); |

|

|

|

r = Radius – ScaleHeight – TickGap – LegendTextSize.y; |

|

|

|

logval = MinLog + 4; |

|

a = offset + logval * Arc; |

|

ArcLegend("←— R XC XL Scale —→",r,a,INWARD); |

|

|

|

comment("Capacitive frequency scale"); |

|

Radius = DeckRad; |

|

|

|

MinLog = 0; |

|

MaxLog = 9; |

|

Arc = ScaleArc; |

|

|

|

dec = 1; |

|

offset = 18 * -ScaleArc; |

|

for (logval = MinLog; logval < MaxLog; logval++) { |

|

a = offset + logval * Arc; |

|

DrawTicks(Radius,TickScaleNarrow,INWARD,a,Arc,dec,OUTWARD,FALSE); |

|

dec = (dec == 100) ? 1 : 10 * dec; |

|

} |

|

|

|

a = offset + MaxLog * Arc; |

|

DrawTicks(Radius,TickScaleNarrow,INWARD,a,Arc,1000,OUTWARD,TRUE); |

|

|

|

r = Radius – (TickMajor + 2*TickGap + LegendTextSize.y); |

|

|

|

logval = MinLog + 1.5; |

|

|

|

a = offset + logval * Arc; |

|

ArcLegend("Hz – hertz",r,a,OUTWARD); |

|

|

|

logval += 3; |

|

a = offset + logval * Arc; |

|

ArcLegend("kHz – kilohertz x10^3",r,a,OUTWARD); |

|

|

|

logval += 3; |

|

a = offset + logval * Arc; |

|

ArcLegend("MHz – megahertz x10^6",r,a,OUTWARD); |

|

|

|

r = Radius – ScaleHeight – TickGap – LegendTextSize.y; |

|

|

|

logval = MaxLog – 3; |

|

a = offset + logval * Arc; |

|

ArcLegend("←— FC Scale —→",r,a,OUTWARD); |

|

|

|

comment("RC Circuit Pointers"); |

|

|

|

local ctr = [0mm,0mm]; |

|

|

|

r0 = DeckRad – 2*ScaleHeight; |

|

r1 = r0 – ScaleHeight; |

|

|

|

a = -(17 * ScaleArc); |

|

|

|

goto(r0 * [cos(a),sin(a)]); |

|

move([-,-,EngraveZ]); |

|

move(r1 * [cos(a),sin(a)]); |

|

goto([-,-,TravelZ]); |

|

ArcLegend("⇓",(r0 – TickGap),a,OUTWARD); |

|

|

|

RadialLegend(" Time Constant",ctr,r1,a,TEXT_LEFT,INWARD,-0.5); |

|

|

|

a += ScaleRT; |

|

|

|

goto(r0 * [cos(a),sin(a)]); |

|

move([-,-,EngraveZ]); |

|

move(r1 * [cos(a),sin(a)]); |

|

goto([-,-,TravelZ]); |

|

ArcLegend("⇓",(r0 – TickGap),a,OUTWARD); |

|

|

|

RadialLegend(" Risetime",ctr,r1,a,TEXT_LEFT,INWARD,-0.5); |

|

|

|

a -= ScaleRT/2; |

|

|

|

RadialLegend(" RC",ctr,r0 – 2*ScaleTextSize.y,a,TEXT_LEFT,INWARD,-0.5); |

|

|

|

comment("L/R Circuit Pointers"); |

|

|

|

r0 = DeckRad; |

|

r1 = r0 – ScaleHeight; |

|

|

|

a = -TauAngle; |

|

|

|

goto(r0 * [cos(a),sin(a)]); |

|

move([-,-,EngraveZ]); |

|

move(r1 * [cos(a),sin(a)]); |

|

goto([-,-,TravelZ]); |

|

ArcLegend("⇓",(r0 – TickGap),a,OUTWARD); |

|

|

|

RadialLegend("Time Constant ",ctr,r1,a,TEXT_RIGHT,OUTWARD,-0.5); |

|

|

|

a -= ScaleRT; |

|

|

|

goto(r0 * [cos(a),sin(a)]); |

|

move([-,-,EngraveZ]); |

|

move(r1 * [cos(a),sin(a)]); |

|

goto([-,-,TravelZ]); |

|

ArcLegend("⇓",(r0 – TickGap),a,OUTWARD); |

|

|

|

RadialLegend("Risetime ",ctr,r1,a,TEXT_RIGHT,OUTWARD,-0.5); |

|

|

|

a += ScaleRT/2; |

|

|

|

RadialLegend("L/R ",ctr,r0 – 2*ScaleTextSize.y,a,TEXT_RIGHT,OUTWARD,-0.5); |

|

|

|

comment("Title and logo"); |

|

|

|

feedrate(TextSpeed); |

|

|

|

r = 0.65*DeckRad; |

|

tp = scale(typeset("Homage",TextFont),TitleTextSize); |

|

tpa = ArcText(tp,[0mm,0mm],r,TitleAngle,TEXT_CENTERED,INWARD); |

|

engrave(tpa,TravelZ,EngraveZ); |

|

|

|

r -= 1.5*TitleTextSize.y; |

|

tp = scale(typeset("Tektronix",TextFont),TitleTextSize); |

|

tpa = ArcText(tp,[0mm,0mm],r,TitleAngle,TEXT_CENTERED,INWARD); |

|

engrave(tpa,TravelZ,EngraveZ); |

|

|

|

r -= 1.5*TitleTextSize.y; |

|

tp = scale(typeset("Circuit Computer",TextFont),TitleTextSize); |

|

tpa = ArcText(tp,[0mm,0mm],r,TitleAngle,TEXT_CENTERED,INWARD); |

|

engrave(tpa,TravelZ,EngraveZ); |

|

|

|

r -= 1.5*TitleTextSize.y; |

|

if (TRUE) { |

|

tp = scale(typeset("TEK 003-023",TextFont),LegendTextSize); |

|

} |

|

else { |

|

tp = scale(typeset("https://vintagetek.org/tektronix-circuit-computer/",TextFont),LegendTextSize); |

|

} |

|

tpa = ArcText(tp,[0mm,0mm],r,TitleAngle,TEXT_CENTERED,INWARD); |

|

engrave(tpa,TravelZ,EngraveZ); |

|

|

|

r = 0.3*DeckRad; |

|

a = TitleAngle + 180deg; |

|

tp = scale(typeset("Ed Nisley",TextFont),LegendTextSize); |

|

tpa = ArcText(tp,[0mm,0mm],r,a,TEXT_CENTERED,OUTWARD); |

|

engrave(tpa,TravelZ,EngraveZ); |

|

|

|

r += 1.5*TitleTextSize.y; |

|

tp = scale(typeset("KE4ZNU",TextFont),LegendTextSize); |

|

tpa = ArcText(tp,[0mm,0mm],r,a,TEXT_CENTERED,OUTWARD); |

|

engrave(tpa,TravelZ,EngraveZ); |

|

|

|

r += 1.5*TitleTextSize.y; |

|

tp = scale(typeset("softsolder.com",TextFont),LegendTextSize); |

|

tpa = ArcText(tp,[0mm,0mm],r,a,TEXT_CENTERED,OUTWARD); |

|

engrave(tpa,TravelZ,EngraveZ); |

|

|

|

goto([-,-,SafeZ]); // done, so get out of the way |

|

goto([0,0,-]); |

|

|

|

comment("Top deck ends"); |

|

|

|

} |

|

|

|

//———- |

|

// Engrave cursor hairline |

|

|

|

function EngraveCursor() { |

|

|

|

// Mark center pivot |

|

|

|

MarkPivot(); |

|

|

|

comment("Cursor hairline"); |

|

|

|

feedrate(ScaleSpeed); |

|

|

|

goto([-,-,TravelZ]); |

|

|

|

repeat(2) { |

|

goto([DeckTopOD/2 – 2.25*ScaleHeight,0,-]); // slight overlap on arrows |

|

move([-,-,EngraveZ]); |

|

move([DeckBottomOD/2 + ScaleHeight,0,-]); |

|

goto([-,-,TravelZ]); |

|

} |

|

|

|

goto([-,-,SafeZ]); // done, so get out of the way |

|

goto([0,0,-]); |

|

|

|

} |

|

|

|

//—————————————————————————– |

|

// Deck milling |

|

// Assumes adhesive clamping to avoid protrusions above work area |

|

|

|

//—– |

|

// Bottom deck |

|

|

|

function MillBottom() { |

|

comment("Mill Bottom"); |

|

|

|

feedrate(KnifeSpeed); |

|

|

|

goto([-,-,TravelZ]); |

|

|

|

local r = PivotOD/2; |

|

goto([0,r,-]); // entry move to align knife |

|

arc_cw([r,0,0],r); // blade enters surface |

|

|

|

move([-,-,KnifeZ]); // apply cutting force |

|

circle_cw([0,0]); |

|

arc_cw([0,-r],r); // cut past entry point |

|

goto([-,-,TravelZ]); |

|

|

|

r = DeckRad; |

|

local a = 5deg; |

|

local p0 = r * [cos(a),sin(a),-]; // entry point |

|

local p1 = r * [cos(-a),sin(-a),-]; // exit point |

|

|

|

goto(p0); |

|

arc_cw([r,0,0],r); // blade enters surface |

|

|

|

move([-,-,KnifeZ]); // apply cutting force |

|

circle_cw([0,0]); // cut circle |

|

|

|

arc_cw(p1,r); // cut past entry point |

|

goto([-,-,TravelZ]); |

|

|

|

goto([0,0,-]); |

|

goto([-,-,SafeZ]); |

|

|

|

} |

|

|

|

//—– |

|

// Middle deck |

|

|

|

function MillMiddle() { |

|

|

|

FLNotchArc = 85deg; // width exposing FL scale |

|

FLRampArc = 7deg; // … width of entry & exit ramps |

|

FLNotchOffset = 2deg; // … start angle from 0° |

|

|

|

comment("Mill Middle"); |

|

|

|

feedrate(KnifeSpeed); |

|

|

|

goto([-,-,TravelZ]); |

|

|

|

local r = PivotOD/2; |

|

goto([0,r,-]); // entry move to align knife |

|

arc_cw([r,0,0],r); // blade enters surface |

|

|

|

move([-,-,KnifeZ]); // apply cutting force |

|

circle_cw([0,0]); |

|

arc_cw([0,-r],r); // cut past entry point |

|

goto([-,-,TravelZ]); |

|

|

|

// FL scale notch |

|

|

|

local r0 = DeckRad; |

|

local a0 = FLNotchOffset; // end of notch ramp |

|

local p0 = r0 * [cos(a0),sin(a0),-]; |

|

|

|

local a1 = a0 + FLNotchArc; // start of notch ramp |

|

local p1 = r0 * [cos(a1),sin(a1),-]; |

|

|

|

goto(p0); |

|

arc_cw([r0,0,0],r0); // blade enters surface |

|

move([-,-,KnifeZ]); // apply cutting force |

|

arc_cw(p1,-r0); // largest arc to start of notch |

|

|

|

local r1 = r0 – ScaleHeight; |

|

local a3 = a1 – FLRampArc; // start of notch base |

|

local p3 = r1 * [cos(a3),sin(a3),-]; |

|

|

|

local a4 = a0 + FLRampArc; // end of notch base |

|

local p4 = r1 * [cos(a4),sin(a4),-]; |

|

|

|

move(p3); |

|

arc_cw(p4,r1); // smallest arc on notch base |

|

|

|

move(p0); // end of notch ramp |

|

arc_cw([r0,0,-],r0); // round off corner |

|

|

|

local p5 = r0 * [cos(-a0),sin(-a0),-]; // small overtravel past entry point |

|

arc_cw(p5,r0); |

|

|

|

goto([-,-,TravelZ]); |

|

|

|

// L/R τ and RT Scale window |

|

|

|

local WindowArc = 39deg; |

|

|

|

ac = -6 * ScaleArc; // center of window arc |

|

r0 = DeckRad – ScaleHeight; // outer |

|

r1 = DeckRad – 2 * ScaleHeight; // inner |

|

|

|

aw = WindowArc – to_deg(atan(ScaleHeight,(r0 + r1)/2)); // window arc minus endcaps |

|

|

|

p0 = r0 * [cos(ac + aw/2),sin(ac + aw/2),-]; // endcap entry & exit |

|

p1 = r0 * [cos(ac – aw/2),sin(ac – aw/2),-]; |

|

p2 = r1 * [cos(ac – aw/2),sin(ac – aw/2),-]; |

|

p3 = r1 * [cos(ac + aw/2),sin(ac + aw/2),-]; |

|

|

|

goto(p3); // cut entry point |

|

arc_cw(p0 +| [-,-,0],ScaleHeight/2); // blade enters surface |

|

move([-,-,KnifeZ]); // apply pressure |

|

|

|

arc_cw(p1,r0); // smallest arc |

|

arc_cw(p2,ScaleHeight/2); // half a circle |

|

arc_ccw(p3,r1); |

|

arc_cw(p0,ScaleHeight/2); |

|

|

|

arc_cw(p1 +| [-,-,TravelZ],r0); // exit from cut |

|

|

|

goto([0,0,-]); |

|

goto([-,-,SafeZ]); |

|

|

|

} |

|

|

|

|

|

//—– |

|

// Top deck |

|

|

|

function MillTop() { |

|

comment("Mill Top"); |

|

|

|

feedrate(KnifeSpeed); |

|

|

|

goto([-,-,TravelZ]); |

|

|

|

local r = PivotOD/2; |

|

goto([0,r,-]); // entry move to align knife |

|

arc_cw([r,0,0],r); // blade enters surface |

|

|

|

move([-,-,KnifeZ]); // apply cutting force |

|

circle_cw([0,0]); |

|

arc_cw([0,-r],r); // cut past entry point |

|

goto([-,-,TravelZ]); |

|

|

|

r = DeckRad; |

|

local a = 5deg; |

|

local p0 = r * [cos(a),sin(a),-]; // entry point |

|

local p1 = r * [cos(-a),sin(-a),-]; // exit point |

|

|

|

goto(p0); |

|

arc_cw([r,0,0],r); // blade enters surface |

|

|

|

move([-,-,KnifeZ]); // apply cutting force |

|

circle_cw([0,0]); // cut circle |

|

|

|

arc_cw(p1,r); // cut past entry point |

|

goto([-,-,TravelZ]); |

|

|

|

// RC τ and RT Scale window |

|

|

|

local WindowArc = 54deg; |

|

|

|

local ac = -17 * ScaleArc + ScaleRT/2; // center of window arc |

|

local r0 = DeckRad – ScaleHeight; // outer |

|

local r1 = DeckRad – 2 * ScaleHeight; // inner |

|

|

|

local aw = WindowArc – to_deg(atan(ScaleHeight,(r0 + r1)/2)); // window arc minus endcaps |

|

|

|

p0 = r0 * [cos(ac + aw/2),sin(ac + aw/2),-]; |

|

p1 = r0 * [cos(ac – aw/2),sin(ac – aw/2),-]; |

|

local p2 = r1 * [cos(ac – aw/2),sin(ac – aw/2),-]; |

|

local p3 = r1 * [cos(ac + aw/2),sin(ac + aw/2),-]; |

|

|

|

goto(p3); |

|

arc_cw(p0 +| [-,-,0],ScaleHeight/2); // blade enters surface |

|

move([-,-,KnifeZ]); // apply pressure |

|

|

|

arc_cw(p1,r0); // smallest arc |

|

arc_cw(p2,ScaleHeight/2); // half a circle |

|

arc_ccw(p3,r1); |

|

arc_cw(p0,ScaleHeight/2); |

|

|

|

arc_cw(p1 +| [-,-,TravelZ],r0); // exit from cut |

|

|

|

goto([0,0,-]); |

|

goto([-,-,SafeZ]); |

|

|

|

|

|

} |

|

|

|

//———- |

|

// Cut cursor outline |

|

|

|

CursorHubOD = 1.0in; |

|

CursorTipWidth = to_inch(9.0/16.0); |

|

CursorTipRadius = to_inch(1.0/16.0); |

|

|

|

function MillCursor() { |

|

|

|

// Mark center pivot |

|

|

|

MarkPivot(); |

|

|

|

comment("Cursor outline"); |

|

|

|

local dr = DeckBottomOD/2; |

|

local hr = CursorHubOD/2; |

|

local a = atan(hr – CursorTipWidth/2,dr); // rough & ready approximation |

|

|

|

local p0 = hr * [sin(a),cos(a),-]; // upper tangent point on hub |

|

|

|

local c1 = [dr – CursorTipRadius,CursorTipWidth/2 – CursorTipRadius*cos(a),-]; |

|

local p1 = c1 + [CursorTipRadius*sin(a),CursorTipRadius*cos(a),-]; |

|

|

|

local p2 = c1 + [CursorTipRadius,0,-]; // around tip radius |

|

|

|

feedrate(KnifeSpeed); |

|

|

|

goto([-,-,TravelZ]); |

|

goto([-hr,0,-]); |

|

move([-,-,EngraveZ]); |

|

|

|

repeat(3) { |

|

arc_cw(p0,hr); |

|

move(p1); |

|

arc_cw(p2,CursorTipRadius); |

|

|

|

move([p2.x,-p2.y,-]); |

|

arc_cw([p1.x,-p1.y,-],CursorTipRadius); |

|

move([p0.x,-p0.y,-]); |

|

arc_cw([-hr,0,-],hr); |

|

} |

|

|

|

goto([-,-,SafeZ]); // done, so get out of the way |

|

goto([0,0,-]); |

|

|

|

} |

|

|

|

//—————————————————————————– |

|

// The actual machining sequences! |

|

|

|

//—– |

|

// Bottom Deck |

|

|

|

if (SelectPart == "Bottom") { |

|

|

|

DeckOD = DeckBottomOD; |

|

DeckRad = DeckOD / 2; |

|

|

|

comment(" OD: ",DeckOD); |

|

|

|

if (Operation == "Engrave") { |

|

EngraveBottom(); |

|

} |

|

elif (Operation == "Mill") { |

|

MillBottom(); |

|

} |

|

else { |

|

error("Invalid operation: ",Operation); |

|

} |

|

|

|

|

|

} |

|

|

|

//—— |

|

// Middle Deck |

|

|

|

if (SelectPart == "Middle") { |

|

|

|

DeckOD = DeckMiddleOD; |

|

DeckRad = DeckOD / 2; |

|

|

|

comment(" OD: ",DeckOD); |

|

|

|

if (Operation == "Engrave") { |

|

EngraveMiddle(); |

|

} |

|

elif (Operation == "Mill") { |

|

MillMiddle(); |

|

} |

|

else { |

|

error("Invalid operation: ",Operation); |

|

} |

|

|

|

} |

|

|

|

//—– |

|

// Top Deck |

|

|

|

if (SelectPart == "Top") { |

|

|

|

DeckOD = DeckTopOD; |

|

DeckRad = DeckOD / 2; |

|

|

|

comment(" OD: ",DeckOD); |

|

|

|

if (Operation == "Engrave") { |

|

EngraveTop(); |

|

} |

|

elif (Operation == "Mill") { |

|

MillTop(); |

|

} |

|

else { |

|

error("Invalid operation: ",Operation); |

|

} |

|

|

|

} |

|

|

|

//—– |

|

// Cursor |

|

|

|

if (SelectPart == "Cursor") { |

|

|

|

DeckOD = DeckBottomOD; |

|

DeckRad = DeckOD / 2; |

|

|

|

comment(" OD: ",DeckOD); |

|

|

|

if (Operation == "Engrave") { |

|

EngraveCursor(); |

|

} |

|

elif (Operation == "Mill") { |

|

MillCursor(); |

|

} |

|

else { |

|

error("Invalid operation: ",Operation); |

|

} |

|

|

|

} |