The health plan I use pays $100 toward the year’s over-the-counter healthcare stuff, although with a caveat: you can only buy the stuff from a specific website. As you might expect, what’s available consists of no-name generic products with absurdly high sticker prices and, just to rub it in, the hundred bucks gets paid in quarterly use-it-or-lose it installments.

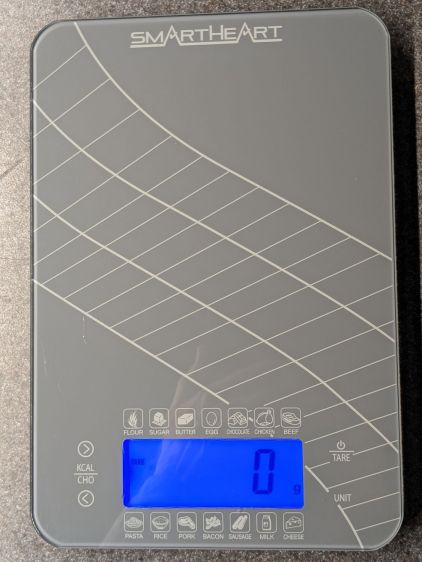

Seeing as how it was free, I got a kitchen scale:

It has two catastrophically bad design features:

- Terrible battery life

- Overly sensitive controls

It runs from a pair of series-connected CR2032 non-rechargeable lithium coin cells. Which would be fine, except that the blue LED backlight stays on for 30 seconds after each button touch and draws about 10 mA.

The battery lifetime is best measured in days.

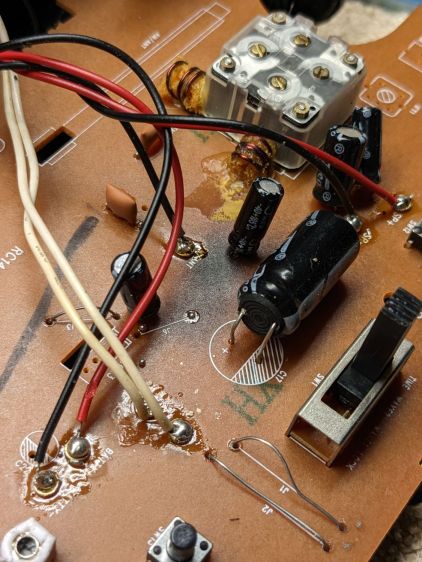

The four control “buttons” on either side of the backlit LCD are touchless sensors using copper foil stickers:

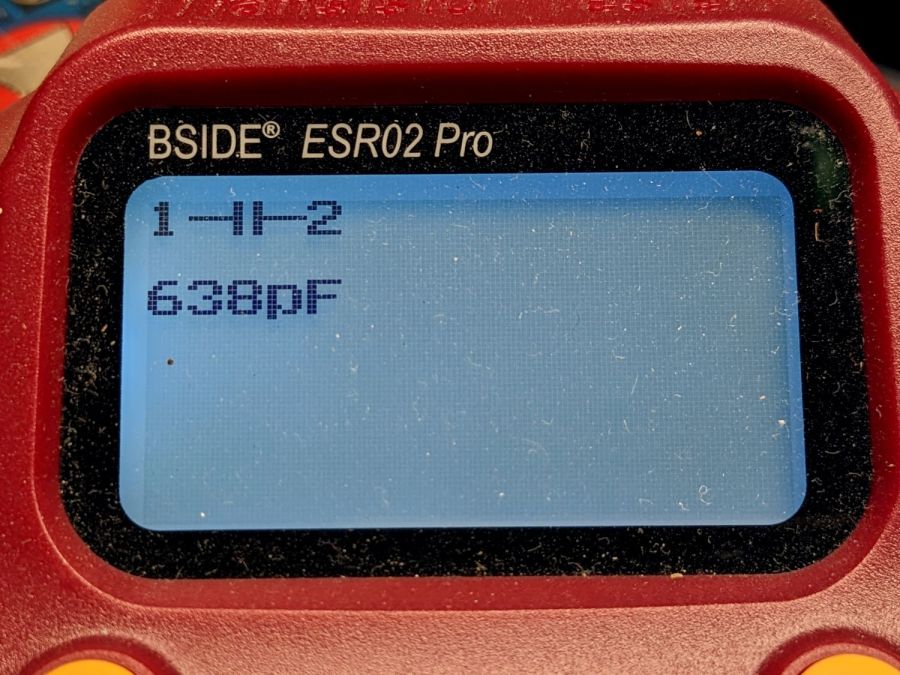

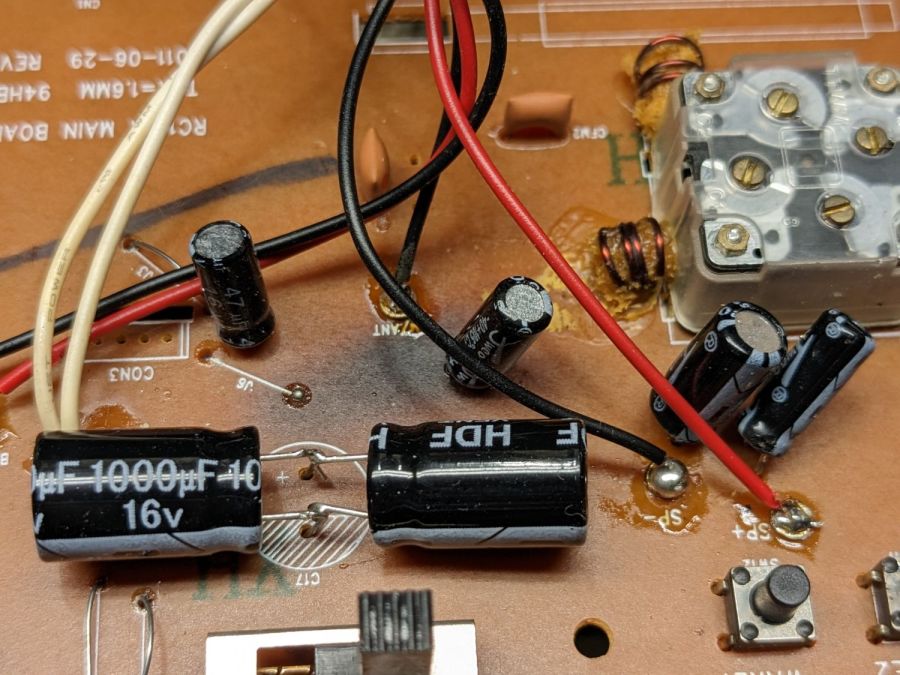

The alert reader will spot those the empty CR2032 coin cell contacts over on the left and a pair of NP-BX1 batteries in the middle.

I figured there was no need to keep feeding it coin cells while I played with it, so I conjured a holder from the vasty digital deep. Normally, that would be an OpenSCAD solid model suited for 3D printing, but in this case the lithium cells exactly filled the space between the PCB and the bottom of the case, so it became a 2D design neatly suited for laser cuttery.

I planned to stick the orange cutout (in 1.5 mm acrylic) as a stabilizer around the pogo pins making contact with the cell terminals from the red cutout (in 3 mm acrylic), but just melting the pins into the acrylic seemed sufficient for the purpose. Strips of adhesive sheet saved from the margins of previous projects affix the holder (not the cells!) to the scale’s upper glass layer.

As far as I can tell, the scale is perfectly happy running on 7.4 V, rather than 6.0 V. The PCB has two terminals marked +3V and +6V, so it probably depends on which LEDs they use for backlights:

The alert reader will notice a peculiarity concerning the sensor pad connections along the top edge.

More on that second bad design decision later …