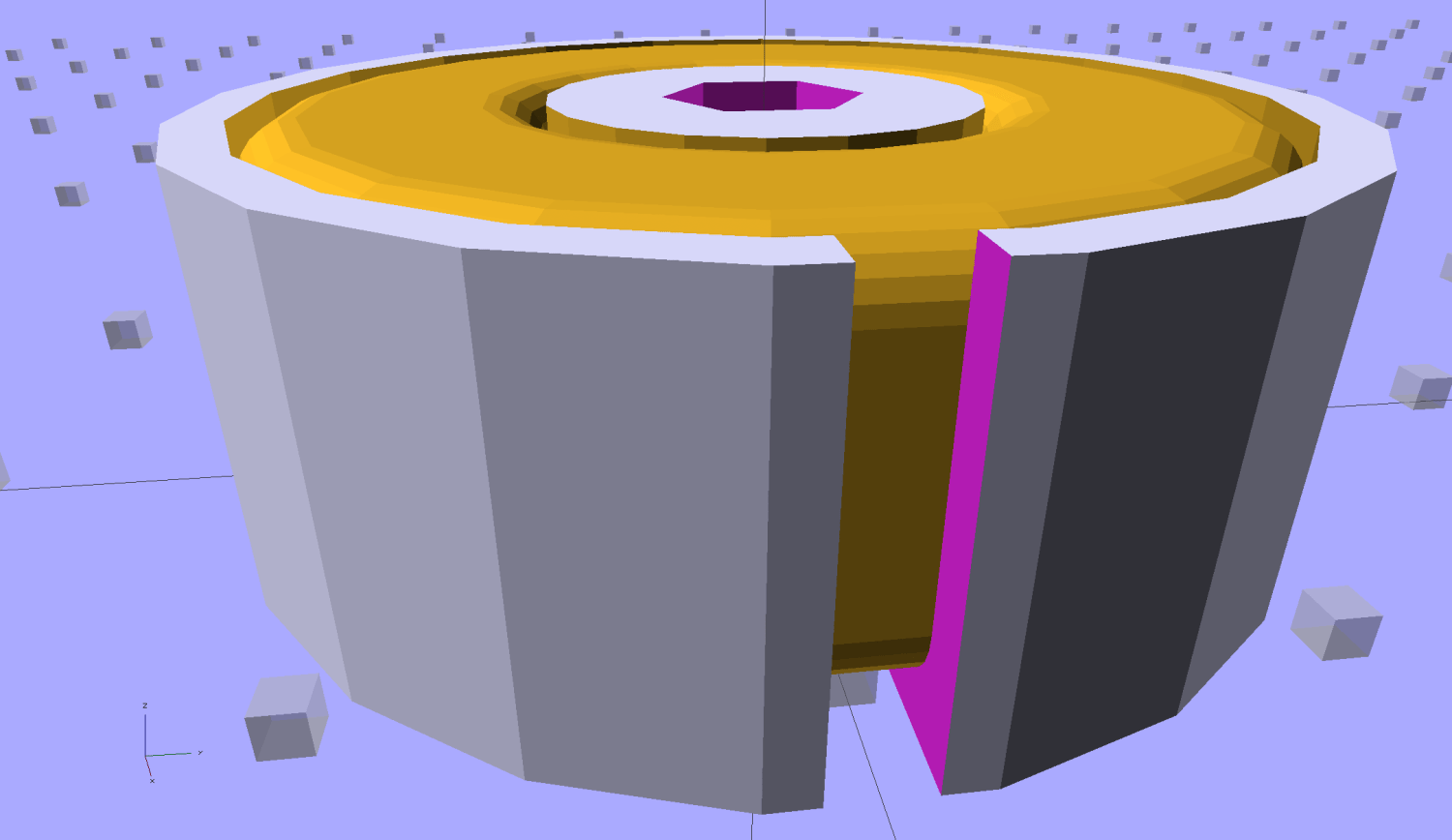

Given the fragility of ferrite toroids in general and slit toroids in particular, a touch of up-armoring seems sensible:

The solid model includes a toroid shell with roughly the right curves:

That puts a nice rounded shape on the bottom of the armor, not that that makes much difference:

The central hole passes a 4-40 brass, nylon, or stainless steel screw. Most of the magnetic field stays within the ferrite and, heck, this isn’t a crazy-sensitive analog application, so even an ordinary steel screw shouldn’t cause any particular problems.

The rectangular (not pie-wedge) slit barely passes the Hall effect sensor.

I’ll pour some clear epoxy over the toroid, with tape masking the ferrite core and sealing the ends, to immobilize the windings. That sounds like a good idea after calibration and suchlike.

The OpenSCAD source code, which should be sufficiently parametric that I can crank ’em out for all the other toroids large enough to accept a screw:

// Toroid coil mounting bracket

// Ed Nisley - KE4ZNU - August 2014

Layout = "Mount"; // Coil Mount Build Show

//- Extrusion parameters must match reality!

// Print with 4 shells and 3 solid layers

ThreadThick = 0.20;

ThreadWidth = 0.40;

HoleWindage = 0.2; // extra clearance

Protrusion = 0.1; // make holes end cleanly

AlignPinOD = 1.70; // assembly alignment pins: filament dia

function IntegerMultiple(Size,Unit) = Unit * ceil(Size / Unit);

//----------------------

// Dimensions

ID = 0; // subscripts for cylindrical objects

OD = 1;

LEN = 2;

Coil = [10.25,23.50,8.3]; // wound toroid core

SensorThick = 2.0;

BaseThick = IntegerMultiple(1.0,ThreadThick); // baseplate under coil

WallThick = IntegerMultiple(1.0,ThreadWidth); // walls beside coil

ScrewHoleDia = 4.0; // allow alignment slop around 3 mm / #4 screws

//----------------------

// Useful routines

module PolyCyl(Dia,Height,ForceSides=0) { // based on nophead's polyholes

Sides = (ForceSides != 0) ? ForceSides : (ceil(Dia) + 2);

FixDia = Dia / cos(180/Sides);

cylinder(r=(FixDia + HoleWindage)/2,

h=Height,

$fn=Sides);

}

module ShowPegGrid(Space = 10.0,Size = 1.0) {

RangeX = floor(100 / Space);

RangeY = floor(125 / Space);

for (x=[-RangeX:RangeX])

for (y=[-RangeY:RangeY])

translate([x*Space,y*Space,Size/2])

%cube(Size,center=true);

}

//----------------------

// Basic coil shape

module CoilShape() {

CornerRadius = min((Coil[LEN] / 2),((Coil[OD] - Coil[ID]) / 2)) / 3;

MidRadius = (Coil[ID] + Coil[OD]) / 4;

HalfX = (Coil[OD] - Coil[ID]) / 4 - CornerRadius;

HalfY = (Coil[LEN] / 2) - CornerRadius;

echo(CornerRadius,MidRadius,HalfX,HalfY);

color("Goldenrod")

render(convexity = 2)

rotate(180/20)

rotate_extrude(convexity=3,$fn=20)

translate([MidRadius,0])

hull()

for (i=[-1,1],j=[-1,1])

translate([i*HalfX,j*HalfY])

circle(r=CornerRadius,$fn=24);

}

//----------------------

// Mount

module Mount() {

difference() {

rotate(180/20)

cylinder(h=(BaseThick + Coil[LEN]),d=(Coil[OD] + 2*WallThick),$fn=20);

translate([0,0,-Coil[LEN]]) // make screw hole

rotate(180/6)

PolyCyl(ScrewHoleDia,3*Coil[LEN],$fn=6);

translate([0,0,BaseThick + Coil[LEN]/2]) // set bottom curve

CoilShape();

translate([0,0,BaseThick + Coil[LEN]]) // clear out top

CoilShape();

translate([(Coil[ID]/2 + Coil[OD]/2),0,0])

cube([Coil[OD],SensorThick,3*Coil[LEN]],center=true);

}

}

ShowPegGrid();

if (Layout == "Coil") {

CoilShape();

}

if (Layout == "Mount")

Mount();

if (Layout == "Show") {

Mount();

translate([0,0,(BaseThick + Coil[LEN]/2)])

CoilShape();

}

if (Layout == "Build") {

Mount();

}