The MOSFET tester spits out datasets using this tedious Arduino code:

void PrintHeader(void) {

Serial.println(); // Gnuplot group break

Serial.println("#-----------------------------");

Serial.print("# VGate: ");

Serial.print(VGateSet,3);

Serial.println();

Serial.print("# TSetpoint: ");

Serial.print(TSetpoint,1);

Serial.println(" C");

Serial.println("# VGS \tVDS \tID \tRDS \tC \tTime");

}

void PrintTempHeader() {

Serial.println(); // Gnuplot index break

Serial.println();

Serial.print("#T="); // ... index name

Serial.println(TSetpoint,1);

Serial.println("#=============================");

Serial.print("# Setting temperature to: "); // human-readable annotation

Serial.print(TSetpoint,1);

Serial.println(" C ...");

}

... later, deep inside the main loop ...

Serial.print(VGateSet,3);

Serial.print('\t');

Serial.print(VDrainSense,3);

Serial.print('\t');

Serial.print(IDrainSense,3);

Serial.print('\t');

Serial.print((IDrainSense == 0.0) ? 0.0 : (VDrainSense / IDrainSense),3);

Serial.print('\t');

Serial.print(Temperature,1);

Serial.print('\t');

Serial.print(millis() - StartTime);

Serial.println();

All that produces a text file formatted to work with Gnuplot, including a blank line between successive gate voltage groups to produce separate plot traces:

#T=0.0 #============================= # Setting temperature to: 0.0 C ... #----------------------------- # VGate: 4.250 # TSetpoint: 0.0 C # VGS VDS ID RDS C Time 4.250 1.200 0.000 0.000 1.0 1757 4.250 1.665 0.044 37.851 1.0 1861 #----------------------------- # VGate: 4.500 # TSetpoint: 0.0 C # VGS VDS ID RDS C Time 4.500 0.003 0.000 0.000 1.0 2038 4.500 0.016 0.044 0.370 1.0 2143 ... snippage ... 4.500 0.212 1.953 0.108 0.9 6105 4.500 0.216 2.001 0.108 0.9 6210

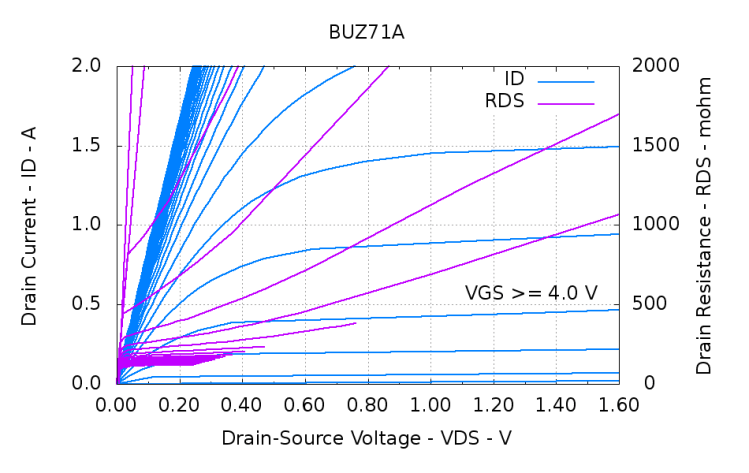

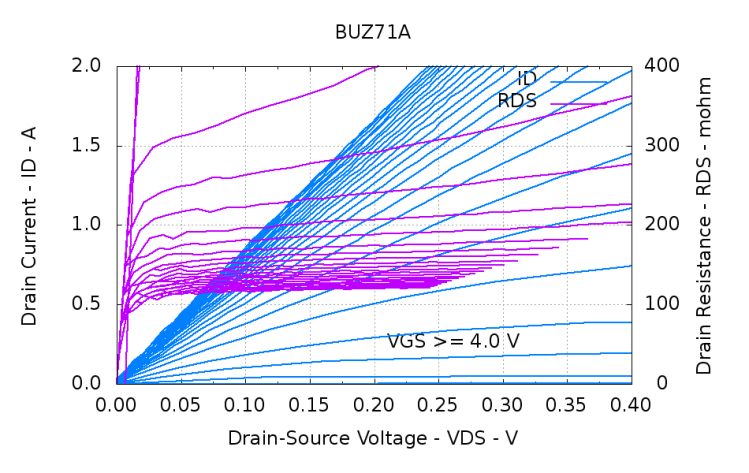

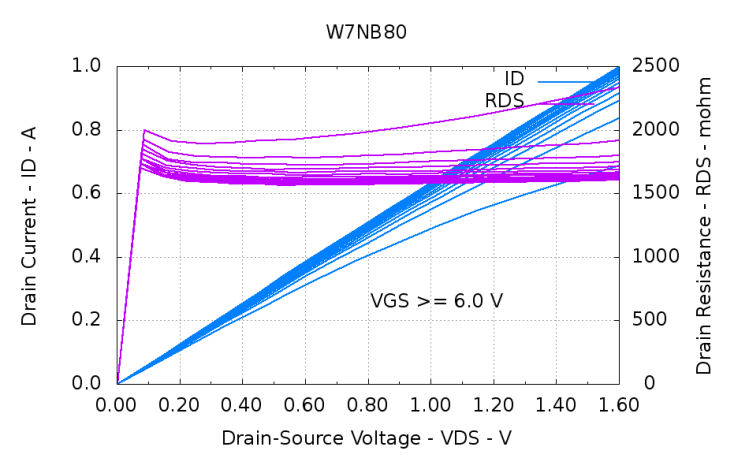

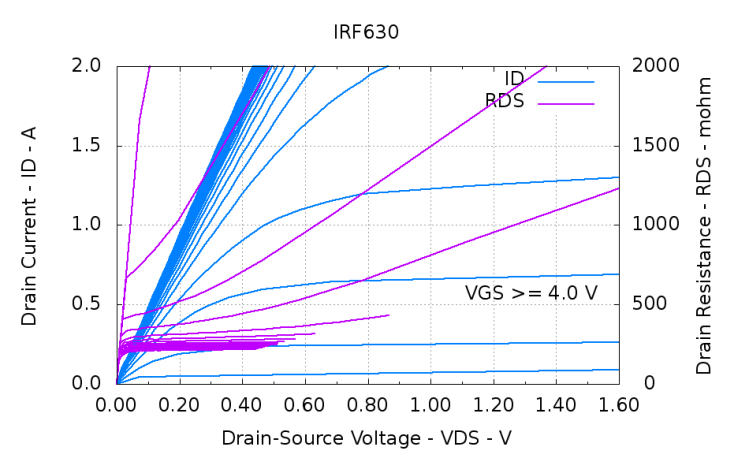

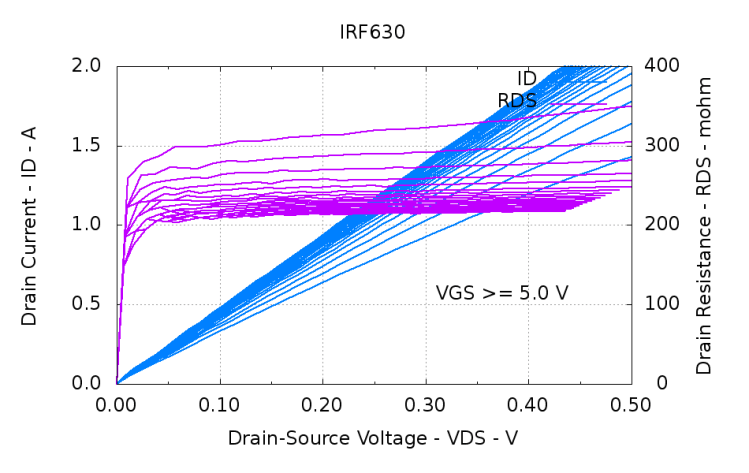

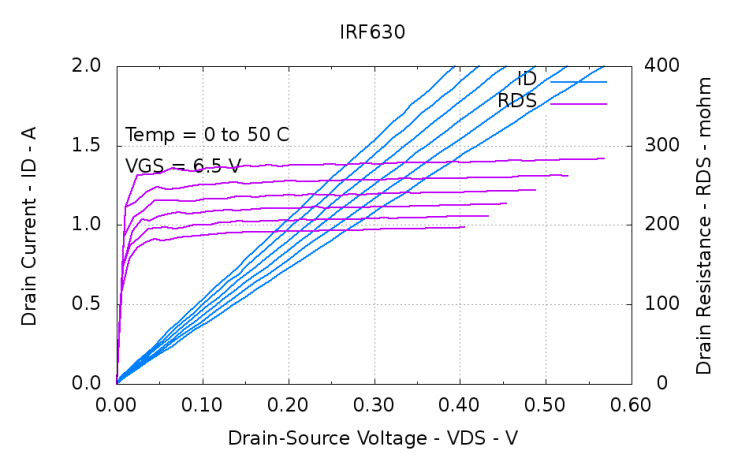

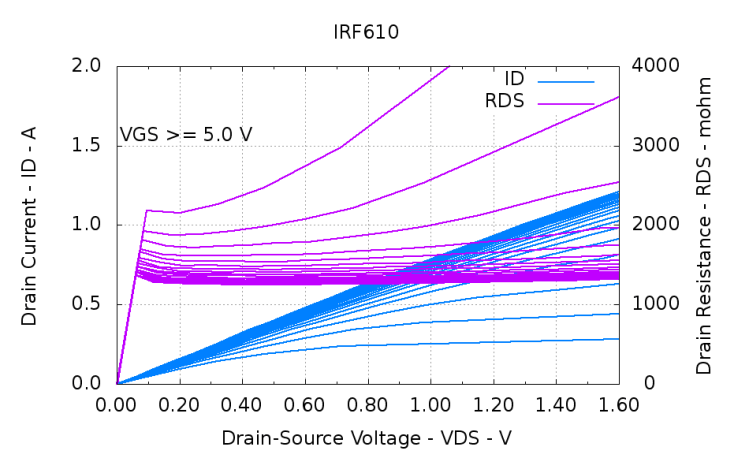

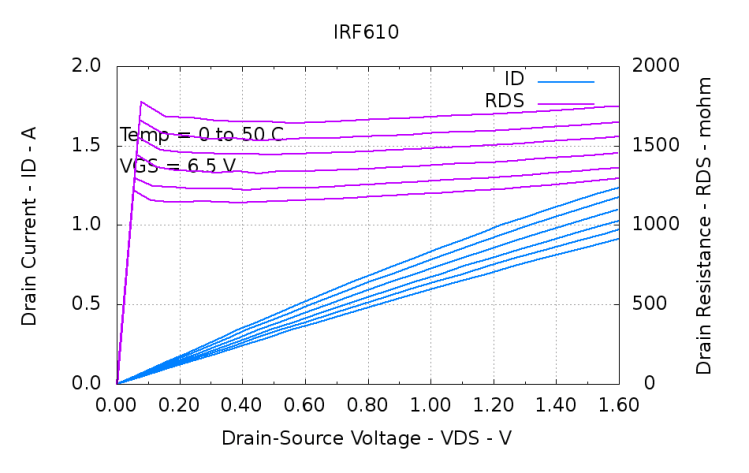

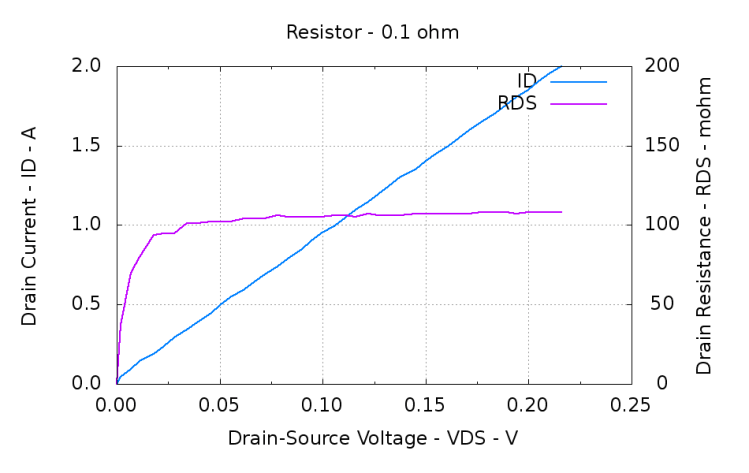

Which produces a plot like this:

It’d be handy to automatically generate labels for the gate voltages, but I haven’t been able to figure out how to read values from the dataset and plunk them into the label strings. You can, however, select blocks of gate voltage and superblocks of temperature with a bit of effort.

The Bash script that feeds Gnuplot looks something like this:

#!/bin/sh

#-- set plot limits

tx=3

vgs_min="4.0"

vds_max="0.2"

rds_max=100

rds_tics=$((${rds_max} / 4))

id_max="2.0"

#-- overhead

export GDFONTPATH="/usr/share/fonts/truetype/"

base="${1%.*}"

echo Base name: ${base}

ofile=${base}.png

echo Output file: ${ofile}

#-- do it

gnuplot << EOF

#set term x11

set term png font "arialbd.ttf" 18 size 950,600

set output "${ofile}"

set title "${base}"

set key noautotitles

unset mouse

set bmargin 4

set grid xtics ytics

set xlabel "Drain-Source Voltage - VDS - V"

set format x "%4.2f"

set xrange [0:${vds_max}]

#set xtics 0,5

set mxtics 2

set ytics nomirror autofreq

set ylabel "Drain Current - ID - A"

set format y "%4.1f"

set yrange [0:${id_max}]

#set mytics 2

set y2label "Drain Resistance - RDS - mohm"

set y2tics nomirror autofreq ${rds_tics}

set format y2 "%3.0f"

set y2range [0:${rds_max}]

#set y2tics 32

#set rmargin 9

set datafile separator "\t"

#set label 1 "Temp index = ${tx}" at 0.81,0.55 font "arialbd,18"

set label 2 "VGS >= ${vgs_min} V" at 0.11,0.55 font "arialbd,18"

plot \

"$1" using 2:((\$1 >= ${vgs_min})?\$3:NaN) index $tx:$tx with lines lt 3 lw 2 title "ID" ,\

"" using 2:((\$1 >= ${vgs_min})?(\$4*1000):NaN) index $tx:$tx axes x1y2 with lines lt 4 lw 2 title "RDS"

EOF

The variables up near the top control the plot limits; it’d be nice to have a complex Bash script that prompted for values, had useful defaults, and fed all that into Gnuplot. Given what I’m doing, it’s easier to just keep the Bash script open in the portrait monitor, watch the results on the landscape monitor, and twiddle until it looks right.

This script produces a plot for a single temperature range based on the superblock index tx; you can select a single block using index name (along the lines of “T=0.0”), but you can’t select multiple such blocks in a single plot statement.

Selecting gate voltages requires testing the first column for a match with the trinary operator and assigning the data value for lines that don’t match to the not-a-number value NaN to prevent it from appearing in the plot:

((\$1 >= ${vgs_min})?\$3:NaN)

All in all, the whole apparat makes for a fairly brittle set of code, but the plots come out ready for printing and that makes up for a lot.