-

OMTech Laser Cutter: Custom Air Fitting Wrench

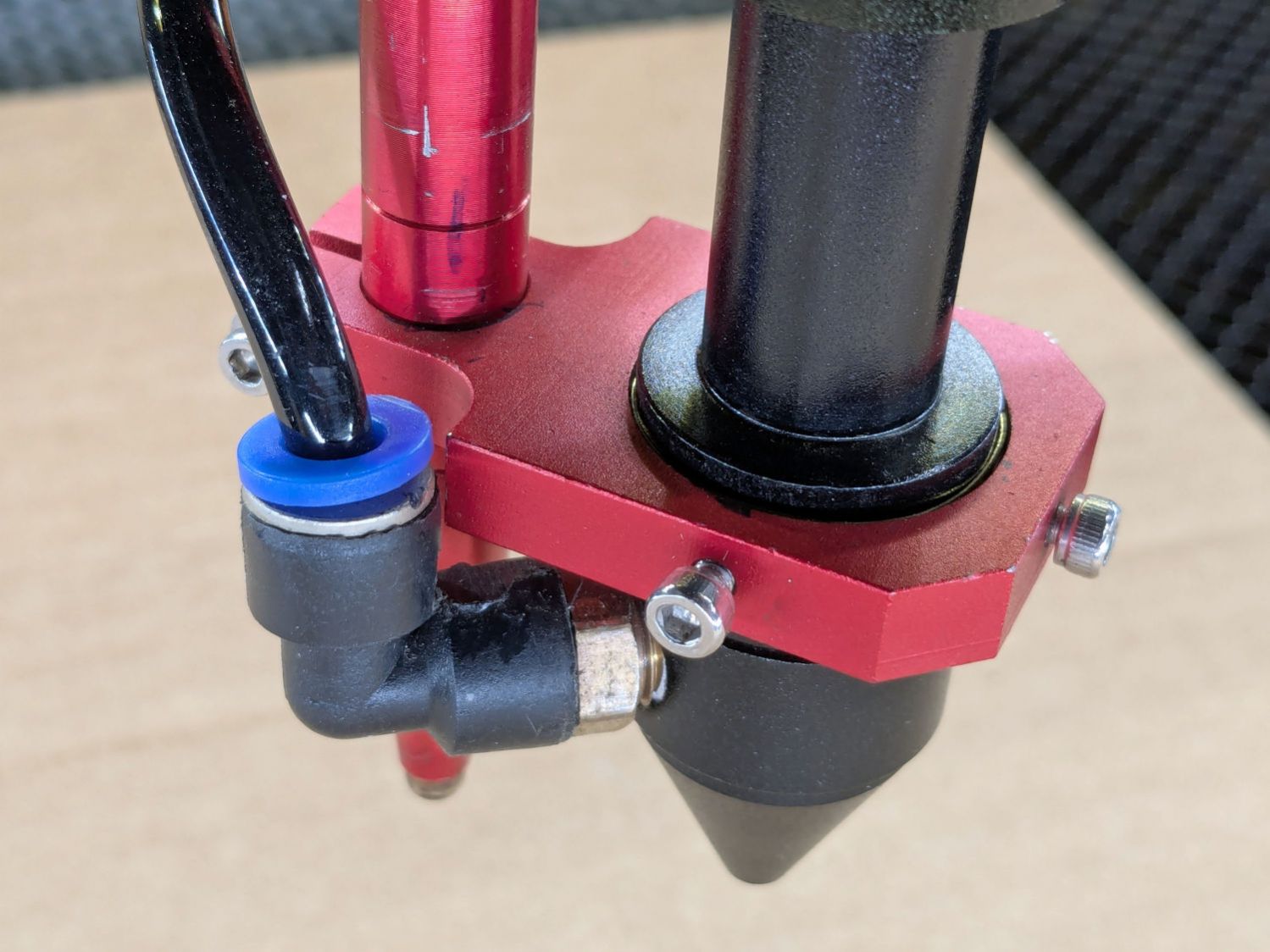

Changing the lens on the laser requires unscrewing the nozzle after removing the assist air fitting that collides with the focus pen holder:

Laser head – assist air vs focus pen All the 12 mm open-end wrenches in my Drawer o’ Spare Wrenches being much too large, I finally got around to making a custom wrench:

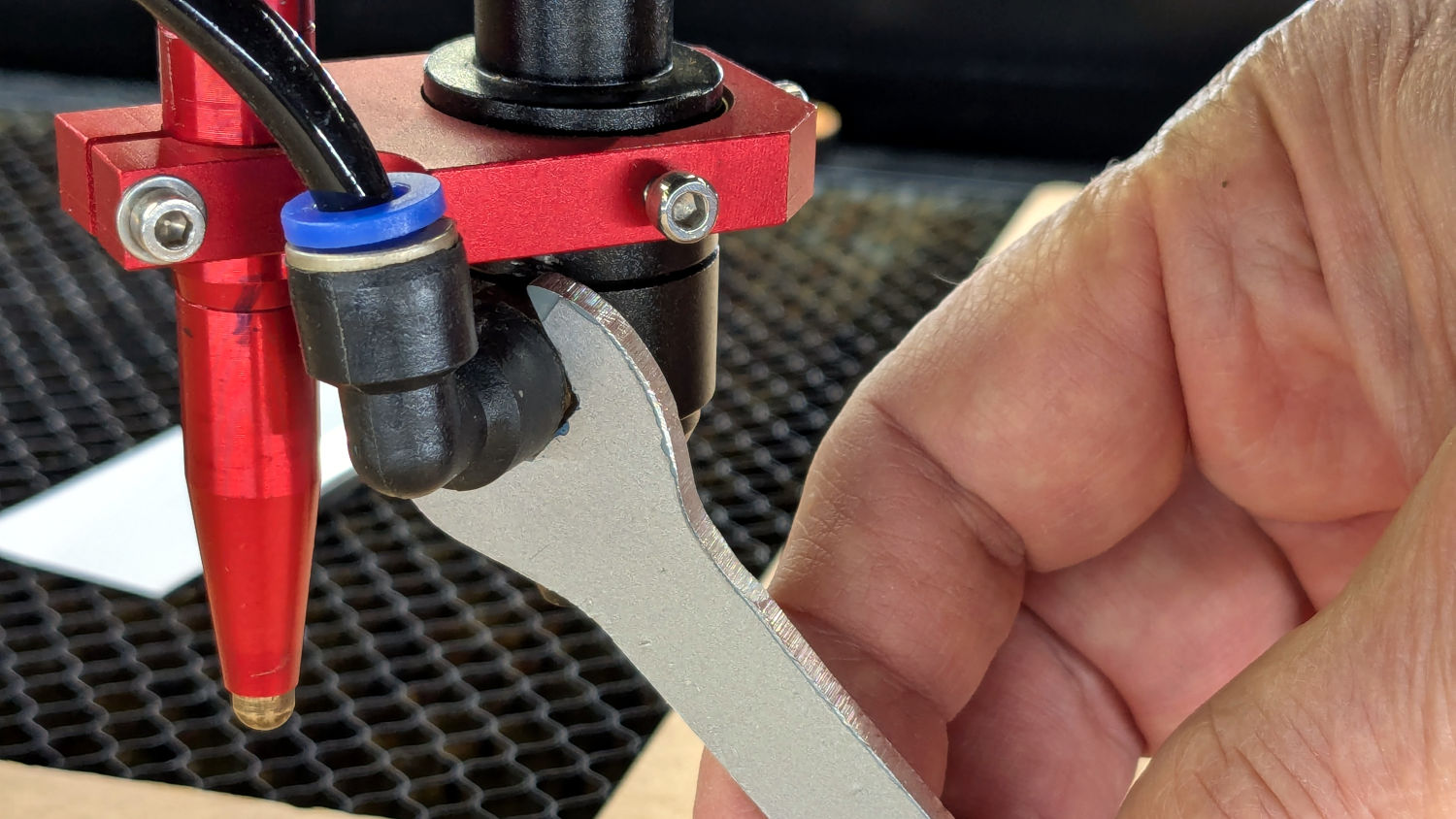

Air fitting wrenches The plywood wrench came from a traced scan of a similar wrench, then adjusting the jaw opening to 12 mm. It served to verify the overall shape & size, then became a template for the real wrench atop a scrap of 1/8 inch aluminum sheet with flaking paint.

Some bandsawing and filing later:

Air fitting wrench – at nozzle A little wrench makes swapping the lens somewhat less tedious, which is a Good Thing™.

Protip: Remember to adjust the

Focus Distanceby the difference between the two lenses.

-

Subscribe

Subscribed

Already have a WordPress.com account? Log in now.