-

Punched Cards: Character Translation & Positioning

With SVG scaling more-or-less settled, converting a line of text into the SVG layouts for printing and punching is

reasonably straightforwardfeasible.The Python program contains several test patterns:

TestStrings = ( " " * NumCols, # blank card for printing "█" * NumCols, # lace card for amusement "0123456789 ABCDEFGHIJKLMNOPQRSTUVWXYZ abcdefghijklmnopqrstuvwxyz", "¢.<(+|!$*);¬,%_>?:#@'=" + '"' + "&-/█", "▯" * NumCols, # hack for row number alignment )A

Contentsstring contains the characters going onto the card, which can come from either the command line orTestStrings:if args.test: # test patterns used without changes Contents = TestStrings[args.test - 1].ljust(NumCols,' ') else: # real cards need cleaning Contents = ''.join(itertools.chain(*args.contents)) if args.seq: nl = 8 - len(args.prefix) Contents = Contents.ljust(NumCols - 8,' ')[:(NumCols - 8)] Contents = Contents + f"{args.prefix}{args.seq:0{nl}d}" else: Contents = Contents.ljust(NumCols,' ')[:NumCols] if not args.lower: Contents = Contents.upper()The

args.seqcommand line option gives either the starting sequence number or, when zero, leaves the original text unchanged. Adding sequence numbers to the Apollo AGC source code is non-canon; so be it. All of the adjusting turnsContentsinto an 80 character string.The

CharMapconverts each Unicode character inContentsinto a list of the holes to be punched in that column:CharMap = { " ": (), "0": (0,), "1": (1,), … snippage … "Z": (10,9), "a": (12,10,1), … snippage … "&": (12,), "-": (11,), "/": (10,1), "█": (12,11,10,1,2,3,4,5,6,7,8,9), # used for lace card test pattern "▯": (12,10,2,4,6,8), # used for alignment tests with hack for row numbers }The numbers in the list are effectively “row names” which must be translated into the physical row index (from the top of the card, because Y coordinates increase downward in SVG files):

RowMap = (2,3,4,5,6,7,8,9,10,11,2,1,0)

The top three card rows are named “12 / 11 / 10”, with the “10 row” in the same place as the “0 row” = third row from the top = index 2, which is why the mapping is not one-to-one.

Whereupon punching the holes goes a little something like this:

if args.layout == "laser": for c in range(len(Contents)): glyph = Contents[c] if not (glyph in CharMap): glyph = ' ' for rn in CharMap[glyph]: r = RowMap[rn] HoleEls.append( svg.Rect( x=svg.mm(BaseHoleAt[X] + c*HoleOC[X] - HoleSize[X]/2), y=svg.mm(BaseHoleAt[Y] + r*HoleOC[Y] - HoleSize[Y]/2), width=svg.mm(HoleSize[X]), height=svg.mm(HoleSize[Y]), stroke=HoleCut, stroke_width=svg.mm(DefStroke), fill="none", ) )Mercifully, everything is in millimeters and LightBurn plunks the holes exactly where they should be:

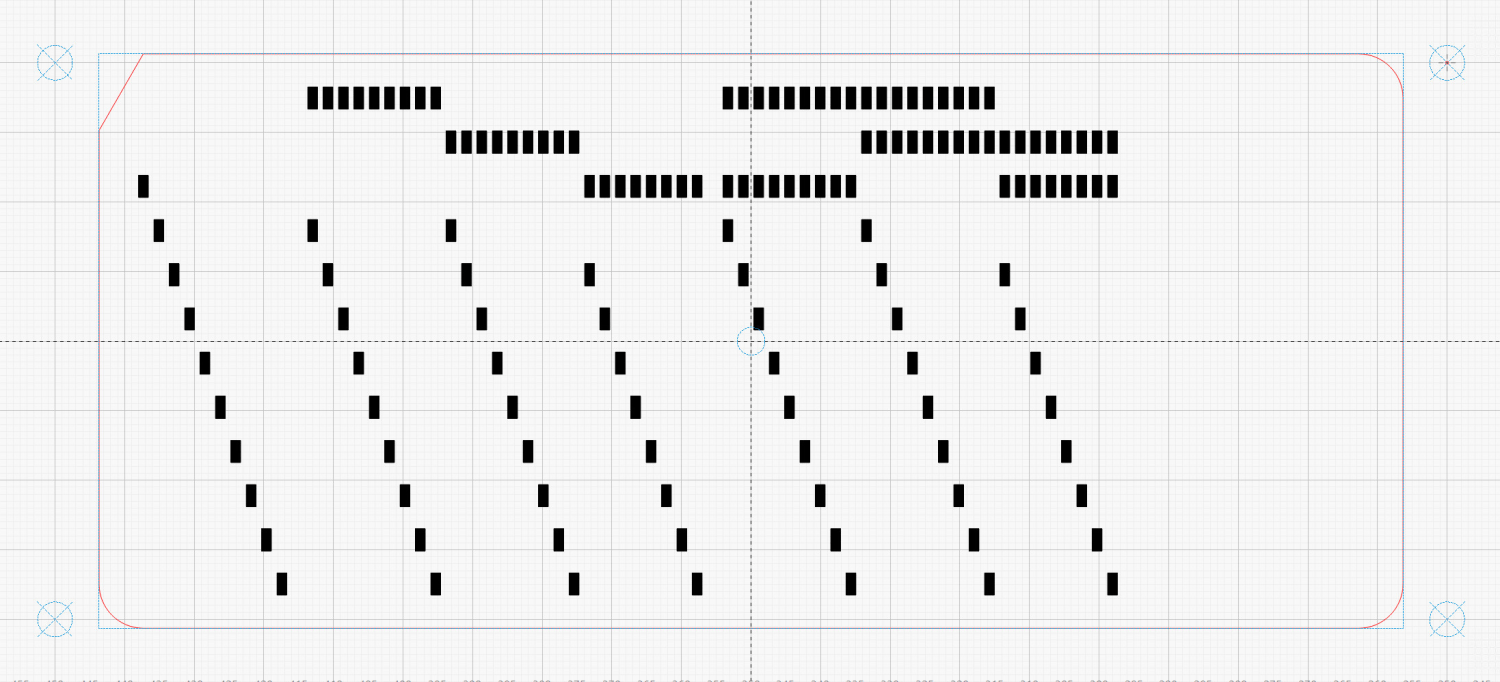

Punched Cards – laser SVG layout That’s the LightBurn layout with the rectangles on the black layer set to

Fill. The SVG rectangles havefill="none"because LightBurn uses only the vector stroke, so you’ll see hollow rectangles in any other program. The card outline goes on the red layer set toLinefor cutting.Punchingevaporating those holes must happen on the printed card made with the same text string, which requires another pass through the program with different command-line parameters.A real blank card has a digit corresponding to the row name printed in every column, much like the bottom card:

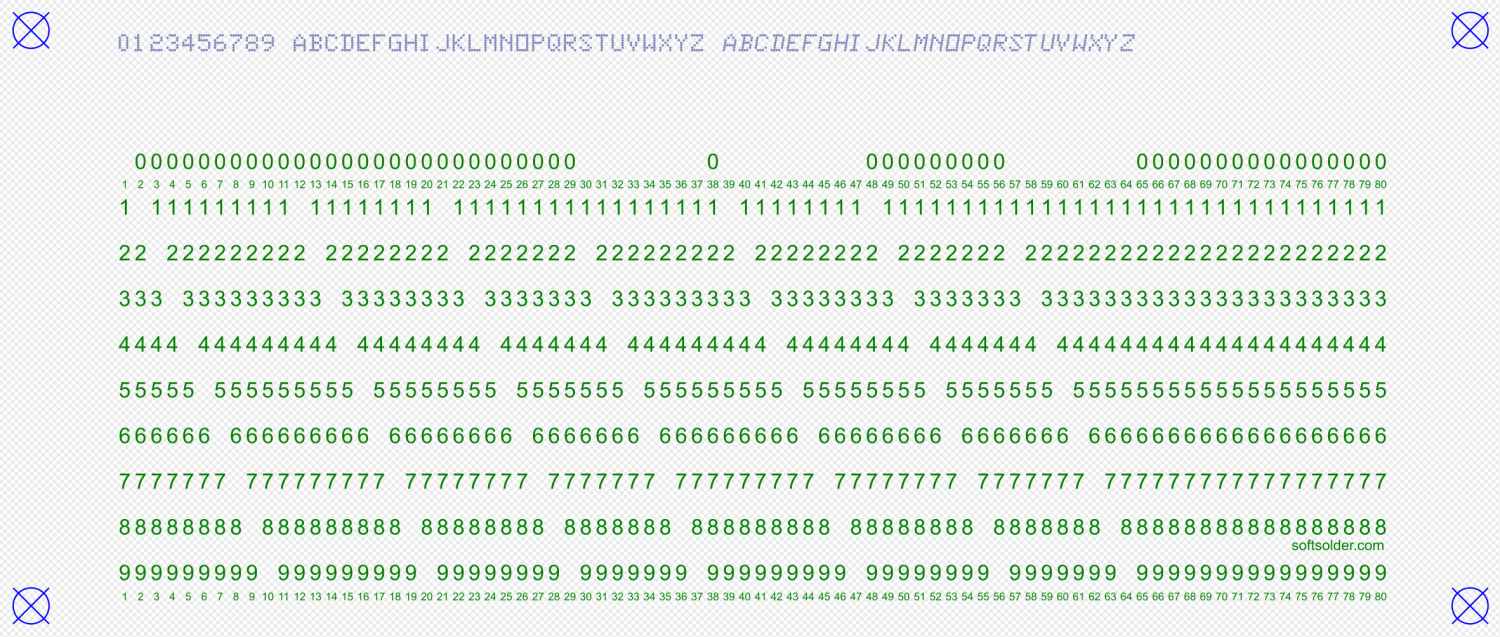

Punched cards – lace and blank tests In these cards, the digits aren’t printed at the positions where holes will appear:

Punched Cards – print SVG layout Preventing a digit sliver from peeking around the edge of a hole makes the text-to-hole alignment look better than it really is. As a bonus, if the holes evaporated in the 9 row don’t match up with the missing digits, poking the

STOPbutton on the laser minimizes the damage; for these cards, I can tolerate a slight punching error.FWIW, back in the day you could get cards printed with any ink color you wanted, as long as you were buying a million or two. While green ink is non-canon for the cards I remember, it was possible.

Not printing a digit requires some gyrations:

if args.layout == "print": xoffset = 0.3 # tiny offsets to align chars with cuts yoffset = 1.5 for c in range(NumCols): glyph = Contents[c] rnx = CharMap[glyph] # will include row name 10 aliased as row name 0 for rn in range(10): pch = RowGlyphs[rn] # default is digit for row if ((rn in rnx) or ((rn == 0) and (10 in rnx))): # suppress punched holes pch = RowGlyphs[-1] if glyph == "▯" else " " # except for alignment tests r = RowMap[rn] TextEls.append( svg.Text( x=svg.mm(BaseHoleAt[X] + c*HoleOC[X] + xoffset), y=svg.mm(BaseHoleAt[Y] + r*HoleOC[Y] + yoffset), class_=["holes"], font_family="Arial", # required by LightBurn font_size="3.0mm", # required by LightBurn text_anchor="middle", text=pch ) )The

xoffsetandyoffsetvalues come from empirical measurements and will likely not match whatever your printer produces.The text and hole layout assume the corner targets have been aligned, so the final alignment depends on at least:

- Eyeballometric positioning of red dot at target center

- Red dot pointer to actual laser spot alignment

- Correct focus distance

- Printer stability in both X and Y

The font gets selected by the

class_andfont_familyattributes, with Inkscape requiring the former and LightBurn the latter. Just to keep things interesting, each program ignores the other attribute. Theclass_attribute selects one of theStyleentries emitted while blurting out the accumulated SVG elements:if not args.debug: canvas = svg.SVG( width=svg.mm(PageSize[X]), height=svg.mm(PageSize[Y]), elements=[ svg.Style( text = f"\n.attrib{{ font: 2mm Arial; fill:{CardText}}}" + f"\n.holes{{ font: 3.0mm Arial; fill:{CardText}}}" + f"\n.cols{{ font: 1.5mm Arial; fill:{CardText}}}" + f"\n.dotty{{ font: 4.0mm KEYPUNCH029; fill:{CardGray}}}" + f"\n.dottylc{{ font: italic 4.0mm KEYPUNCH029; fill:{CardGray}}}" ), ToolEls, MarkEls, CardEls, TextEls, HoleEls, ], ) print(canvas)The

print(canvas)statement squirts the SVG text tostdout, where the Bash script directs it into a suitable file.The

Contentsstring appears across the top of the card in a dark-ish gray-ish color resembling a well-worn IBM 029 keypunch machine ribbon, with theKEYPUNCH029font providing gritty 5×7 verisimilitude:if args.layout == "print": xoffset = 0.3 for c in range(len(Contents)): glyph = Contents[c] if not (glyph in CharMap): glyph = ' ' fc = "dottylc" if curses.ascii.islower(glyph) else "dotty" glyph = svg.escape(glyph) # escape the characters that wreck SVG syntax TextEls.append( svg.Text( x=svg.mm(BaseHoleAt[X] + c*HoleOC[X] + xoffset), y=svg.mm(5.0), # align just below card edge class_=[fc], font_family="KEYPUNCH029", # required by LightBurn font_size="4.0mm", # required by LightBurn text_anchor="middle", text=glyph ) )Although lowercase letters on a punched card are definitely non-canon, the

args.lowercommand-line switch applies italic to them and the font maps them to uppercase.Dumping unfiltered text into an SVG file allows code injection attacks, which I discovered when this test card passed through:

"¢.<(+|!$*);¬,%_>?:#@'=" + '"' + "&-/█"

The

svg.escape()function replaces characters like “&” with “&”., which I filed under “Things I should have learned by now.”Two passes through the program with appropriate switches and the same text will produce two matching SVG files. Although they’re scaled to the same size, the SVG-to-be-printed requires considerable processing before the printer sees it …

-

Subscribe

Subscribed

Already have a WordPress.com account? Log in now.