-

HBP + Aluminum Build Plate + ABS Film = Win!

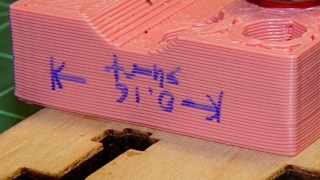

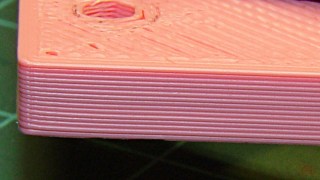

A close look at the first few layers of some recent objects shows why I’m willing to put up with all the hassle described over the last few weeks.

For small objects, take a look at my build of coasterman’s calibration set:

50 mm tower – build detail

Leach field plug – build detail

X Rod Follower – build detail Microscope LED ring light (two pieces glued on the obvious line):

Microscope ring light – build detail Fan adapter plate:

Fan adapter plate – build detail Companion cube, with a slightly warped right corner:

Companion Cube – build detail Now, those objects may have other problems, but two things work really well:

- The first layer sticks like it was glued to the ABS film

- The side walls build perfectly straight, without bulges or shrinkage

What’s important to me: this is dependable and repeatable.

It’s not yet a simple routine, because these objects were built while I was hacking away at the HBP + aluminum plate platform, some are on the old ABP + aluminum plate arrangement, and they’re not all first-attempt parts. However, given a proper setup, It. Just. Works.

Part of the process involves a very slow first-layer feed: about 10 mm/s. At that pace the molten ABS has enough time to bond with the layer on the plate, even around corners; much faster and it can pull free.

The Extruder runs at 210 °C, the HBP at 120 °C, feed is 40 mm/s, and traverse is around 50 mm/s.

It is yet to be seen if this lashup will remain stable, but the first indications seem pretty good.

-

Subscribe

Subscribed

Already have a WordPress.com account? Log in now.